Reflective heat-insulation exterior wall coating and preparation method thereof

A technology of exterior wall coatings and coating additives, applied in the direction of reflection/signal coatings, rosin coatings, coatings, etc., can solve the problems of failure to meet expectations during the use of heat insulation materials, reduced stain resistance of coating films, rough coatings, etc. problems, to achieve the effects of fast bonding, overall weather resistance and aging resistance, and strong thixotropic adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

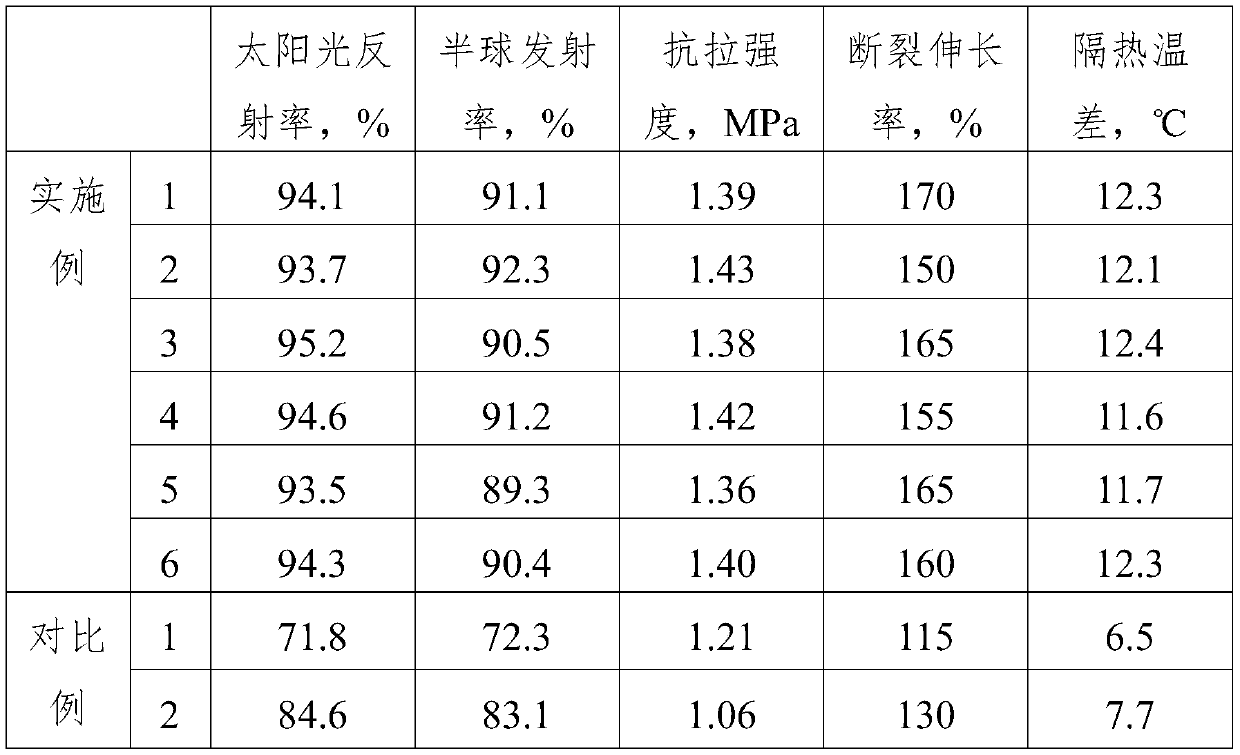

Examples

Embodiment 1

[0031] A reflective and heat-insulating exterior wall paint, comprising the following components in mass percentage: 12% of ceramic waste, 10% of nano-titanium dioxide, 5% of prefabricated fiber particles, 30% of functional filler, 7% of paint additives, and the balance of composite emulsion.

[0032] in:

[0033] Ceramic waste includes: Si≥40wt%, Zr≥34wt%, Al≥15wt%, Zn≥2.2wt%, Mg≥0.6wt%, Ca≤0.5wt%, RE≤0.5wt%, B≤0.2wt%.

[0034] The prefabricated fiber particles include the following raw materials in parts by weight: 1.2 parts of magnesium borate whiskers, 10 parts of wollastonite, 5 parts of sepiolite, 1 part of tourmaline, 1 part of expanded graphite, and 1 part of copper acetate; the preparation method of the prefabricated fiber particles is as follows: :

[0035] 1) Take the materials according to the mass ratio first, place the magnesium borate whiskers in 200°C superheated steam containing 25vt% nitrogen for heat treatment for 1 hour, and dry them with hot air at 85-90°...

Embodiment 2

[0049] A reflective and heat-insulating exterior wall paint, comprising the following components in mass percentage: 15% of ceramic waste, 13% of nano-titanium dioxide, 5% of prefabricated fiber particles, 25% of functional filler, 8% of paint additives, and the balance of composite emulsion.

[0050] in:

[0051] Ceramic waste includes: Si≥40wt%, Zr≥34wt%, Al≥15wt%, Zn≥2.2wt%, Mg≥0.6wt%, Ca≤0.5wt%, RE≤0.5wt%, B≤0.2wt%.

[0052] The prefabricated fiber particles include the following raw materials in parts by weight: 1.4 parts of magnesium borate whiskers, 8 parts of wollastonite, 6 parts of sepiolite, 1.2 parts of tourmaline, 0.8 parts of expanded graphite, and 1 part of copper acetate; the preparation method of the prefabricated fiber particles is :

[0053] 1) Take the materials according to the mass ratio first, place the magnesium borate whiskers in 180°C superheated steam containing 25vt% nitrogen for heat treatment for 1 hour, and dry them with hot air at 85-90°C after...

Embodiment 3

[0062] A reflective and heat-insulating exterior wall paint, comprising the following components in mass percentage: 10% of ceramic waste, 13% of nano-titanium dioxide, 7% of prefabricated fiber particles, 30% of functional filler, 10% of paint additives, and the balance of composite emulsion.

[0063] in:

[0064] Ceramic waste includes: Si≥40wt%, Zr≥34wt%, Al≥15wt%, Zn≥2.2wt%, Mg≥0.6wt%, Ca≤0.5wt%, RE≤0.5wt%, B≤0.2wt%.

[0065] The prefabricated fiber particles include the following raw materials in parts by weight: 0.9 parts of magnesium borate whiskers, 10 parts of wollastonite, 7 parts of sepiolite, 1 part of tourmaline, 0.5 parts of expanded graphite, and 1 part of copper acetate; the preparation method of the prefabricated fiber particles is as follows: :

[0066] 1) Take the materials according to the mass ratio first, place the magnesium borate whiskers in 200°C superheated steam containing 20vt% nitrogen for heat treatment for 1 hour, and dry them with hot air at 85...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com