High-stability concrete silicone joint glue and preparing method thereof

A high stability, concrete technology, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of easy pollution, increased crosslink density, increased modulus, etc., to achieve performance And the effect of improved stability, excellent plasticizing performance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

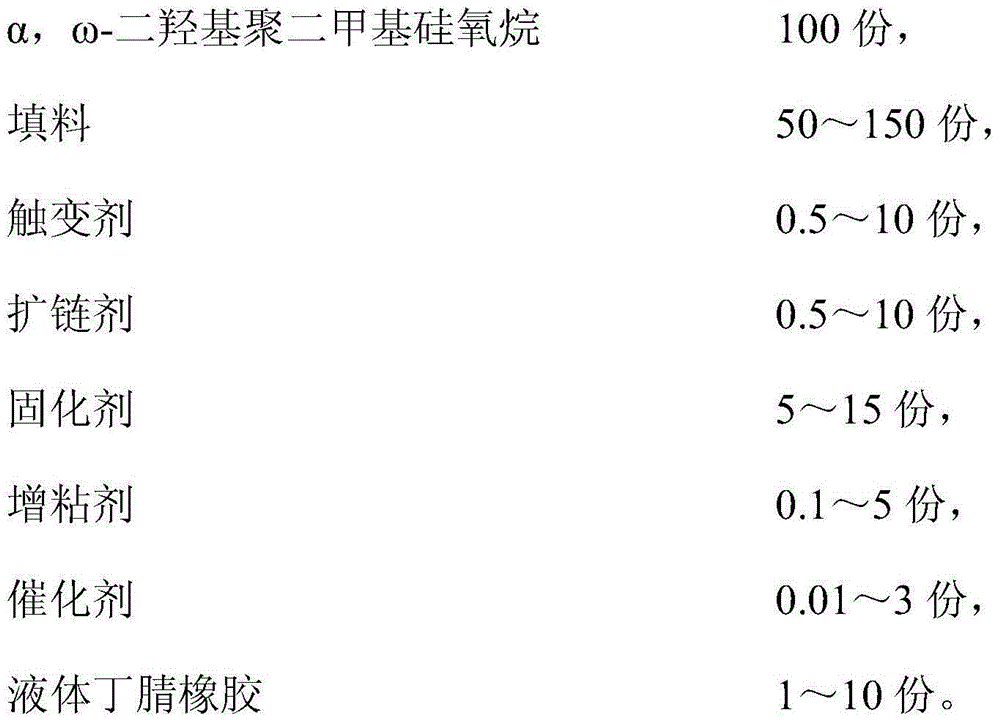

Method used

Image

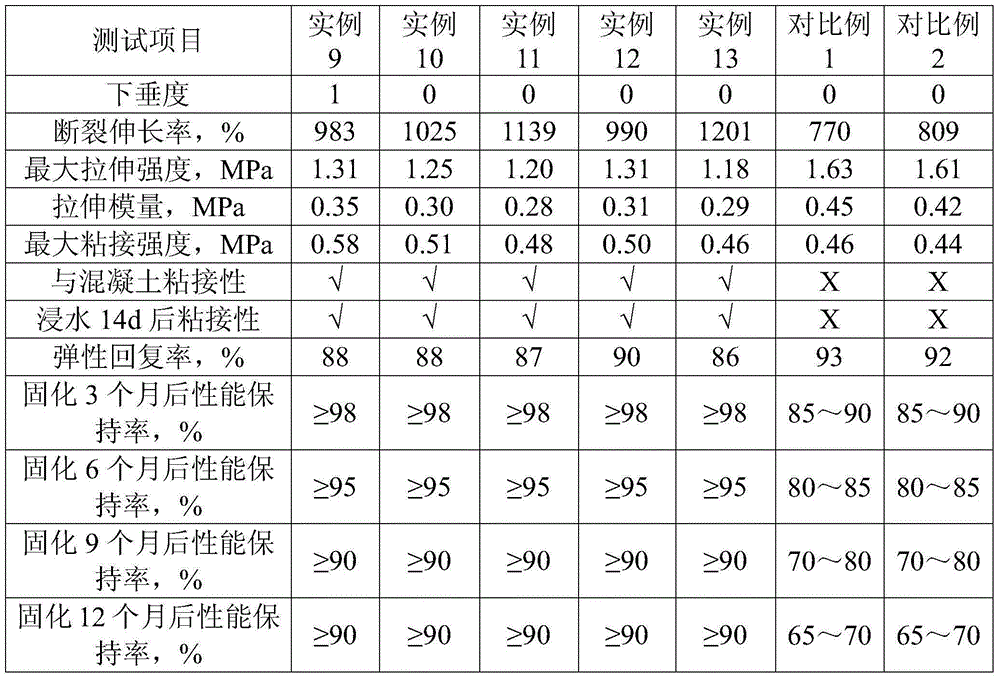

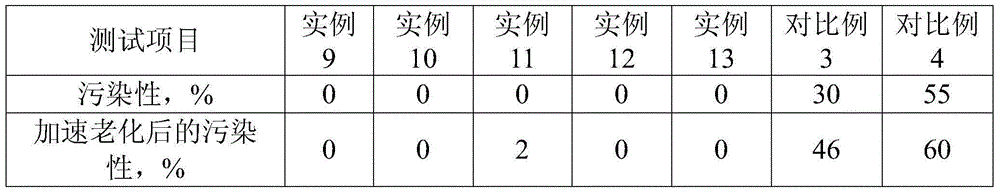

Examples

preparation example Construction

[0049] Preparation of raw materials:

[0050] Add 209.9g (4.58mol) of absolute ethanol and 500mL of petroleum ether into a 3L three-necked flask, keep the nitrogen flow rate at 0.1ml / min, stir evenly in an ice-water bath, control the internal temperature at about 10°C, and then add 300g of (1.85mol) (chloromethyl)methyldichlorosilane, after about 1 hour of dropwise addition, the reaction was continued at 40°C for 3 hours. Then, the solvent and unreacted ethanol are evaporated under a vacuum of 0.05Mpa, and then rectified at normal pressure, and the product at 94-95 ° C is collected to obtain 320 g of colorless and transparent (chloromethyl) methyldiethoxysilane. The yield 96%.

[0051] Preparation of (Chloromethyl)methylethoxybutanoneoximinosilane

[0052] Add 300g (1.85mol) (chloromethyl)methyldichlorosilane, 500ml petroleum ether and 387.2g (3.83mol) triethylamine into a 3L three-necked flask, stir evenly in an ice-water bath, and control the internal temperature at 10 ℃,...

Embodiment 1

[0055] Put 290.8g (1.59mol) (chloromethyl) methyldiethoxysilane, 152.2g (1.75mol) morpholine, 178.2g (1.75mol) triethylamine, 0.4gKI and 800mL petroleum ether into a 3L three-necked flask , After reacting at 60°C for 4h under the protection of nitrogen. The triethylamine hydrochloride that generates is removed by filtration, and the filtrate is rotary evaporated to remove solvent and unreacted triethylamine and morpholine, and rectification, collect 125-132 ℃ / 10mmHg product, obtain orange-yellow transparent (morpholine methyl ) 294.1 g of methyldiethoxysilane, yield 79.4%.

[0056] 1 HNMR (300MHz, CDCl 3 ), δ3.67(4H), 3.60(4H), 2.45(4H), 2.20(2H), 1.10(6H), 0.16(3H)

[0057] Elemental analysis: C% 51.39, H% 9.88, N% 5.94.

Embodiment 2

[0059] Put 132g (0.5mol) (chloromethyl) methyl dibutylketoxime base silane, 46.2g (0.53mol) morpholine, 53.6g (0.53mol) triethylamine, 0.2gKI and 300ml petroleum ether into a 1L three-necked flask After reacting at 75°C for 6h under the protection of nitrogen, the generated triethylamine hydrochloride was removed by filtration, and the filtrate was rotary evaporated to remove the solvent, unreacted triethylamine and morpholine, and then rectified, and collected at 143-150°C / 8mmHg As a product, 118.2 g of orange-yellow transparent (morpholinomethyl)methyldibutanoximinosilane was obtained, with a yield of 74.9%.

[0060] 1 HNMR (300MHz, CDCl 3 ), δ3.63(4H), 2.40(14H), 2.18(2H), 1.08(6H), 0.18(3H)

[0061] Elemental analysis: C% 53.31, H% 9.25, N% 13.29.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com