Luminescent material and preparation method and application thereof

A luminescent material, energy storage luminescence technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of loss of weather resistance, toxicity of degradation products, environmental damage, etc. , The effect of improving flame retardant and fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

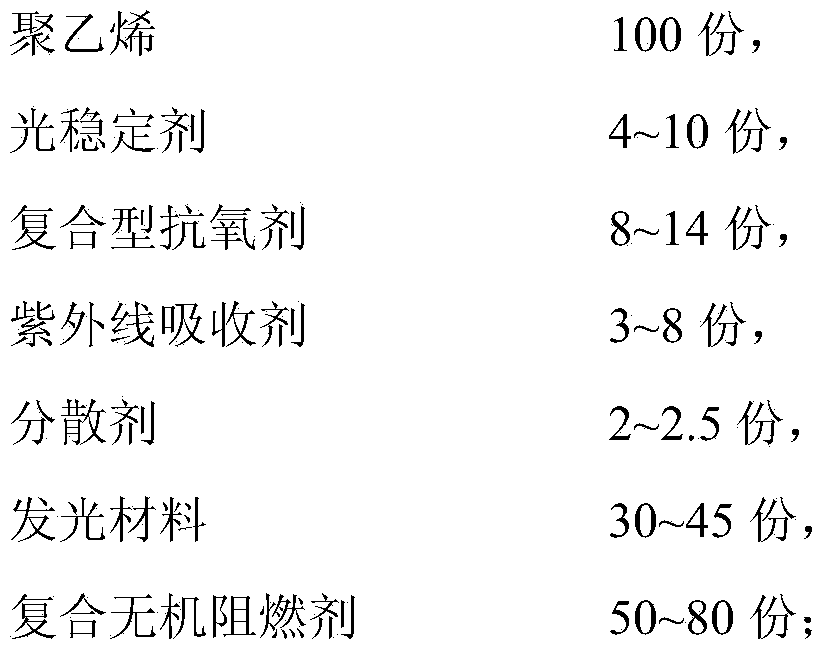

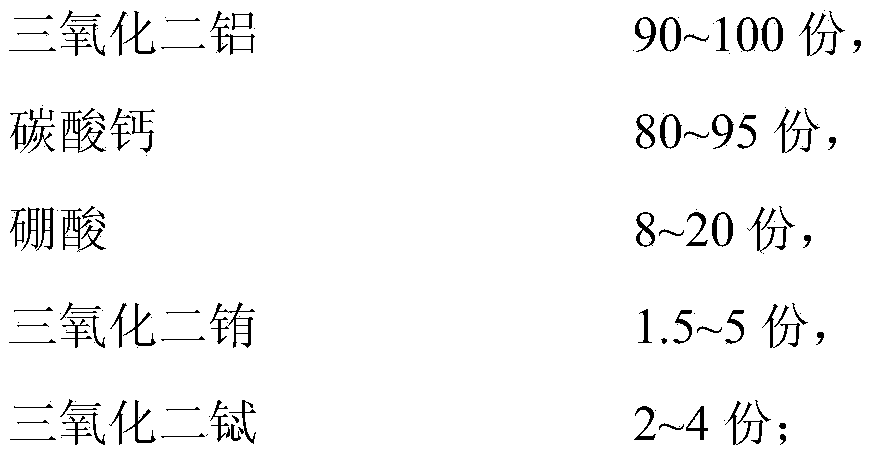

Method used

Image

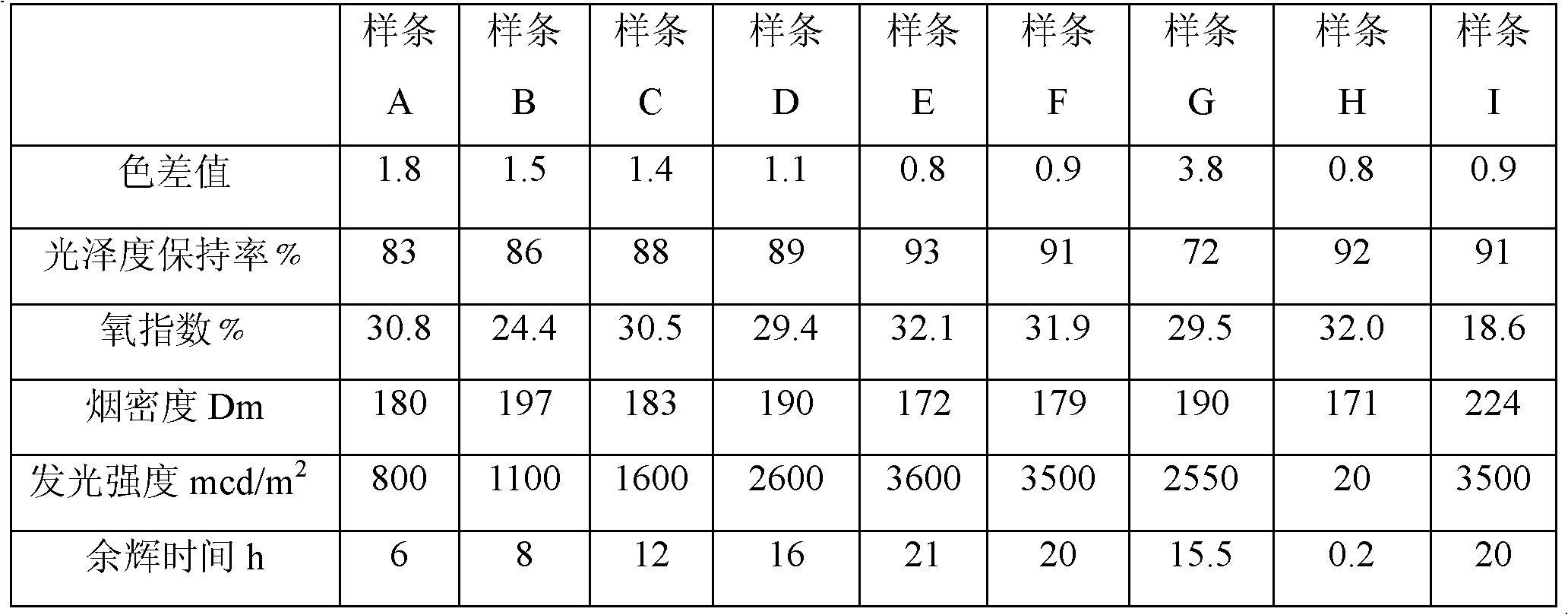

Examples

Embodiment 1

[0045] Prepare the luminescent material first, according to the weight of the luminescent material components: 100 parts of aluminum oxide, 85 parts of calcium carbonate, 10 parts of boric acid, 1.8 parts of europium trioxide, and 2.1 parts of diterbium trioxide. Prepare the raw materials and fully grind the raw materials After mixing through a 500-mesh sieve, put it into an alumina crucible, cover the raw material with a layer of activated carbon with a thickness of 8-12 mm, then install a sealing cover on the crucible and compact the raw material in it, and turn the crucible upside down on the Heating and roasting in a resistance furnace. From 20°C to 200°C, the temperature rise rate is 5-8°C / min. After 200°C, the temperature rise rate is 5-10°C / min. When the temperature reaches 1400°C, keep it for 6-8 hours, and then power off the roasting furnace. After natural cooling for 20 minutes, the crucible was taken out from the roasting furnace, cooled to room temperature naturall...

Embodiment 2

[0050]First prepare the luminescent material, prepare the raw materials according to the weight of the luminescent material components: 90 parts of aluminum oxide, 88 parts of calcium carbonate, 10 parts of boric acid, 2.2 parts of europium trioxide, and 2.1 parts of terbium trioxide. The preparation process is as follows: The same as Example 1, the crucible was taken out from the calcining furnace after the calcining furnace was powered off for natural cooling for 28 minutes, and then cooled to room temperature naturally.

[0051] Combine 34 parts of luminescent material with polyethylene (80 parts of low density polyethylene and 20 parts of linear low density polyethylene), tris (1,2,2,6,6-pentamethylpiperidine) phosphite (GW540) 5.5 parts, complex antioxidant (4.4 parts of octadecyl thiodipropionate and 5.2 parts of antioxidant DLTP), UV-328 (2-(2'-hydroxy-3', 5'-dipentylphenyl) ) 5.8 parts of benzotriazole), 2.2 parts of polyethylene wax, composite inorganic flame retardan...

Embodiment 3

[0055] First prepare the luminescent material, prepare the raw materials according to the weight of the luminescent material components: 95 parts of aluminum oxide, 85 parts of calcium carbonate, 14 parts of boric acid, 2.8 parts of europium trioxide, and 2.5 parts of terbium trioxide. The preparation process is as follows: The same as in Example 1, the calcining furnace was powered off for natural cooling for 18 minutes, and then the crucible was taken out of the calcining furnace and cooled to room temperature naturally.

[0056] Combine 38 parts of luminescent material with polyethylene (80 parts of low density polyethylene and 20 parts of linear low density polyethylene), tris (1,2,2,6,6-pentamethylpiperidine) phosphite (GW540) 7.8 parts, composite antioxidant (5.8 parts of antioxidant CA and 6.6 parts of antioxidant DLTP), UV-329 (2-(2'-hydroxy-5'-tert-octylphenyl) benzotriazole ) 4.8 parts, 2.4 parts of polyethylene wax, composite inorganic flame retardant (50 parts of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com