Aluminum-based metal glass cladding layer and preparation method thereof

A technology of aluminum-based metallic glass and cladding layer, applied in metal processing equipment, metal material coating technology, coating and other directions, can solve the problem of difficulty in preparing high-performance amorphous aluminum alloy materials, limited amorphous forming ability, The problem of high critical cooling rate can improve the internal defects of the molten pool, improve the ability of amorphous formation, and reduce the temperature gradient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0039] The element composition of the aluminum-based amorphous alloy powder used in the aluminum-based metallic glass cladding layer of this embodiment is as follows: 6wt% Ni, 4.5wt% Y, 2wt% Co, 1.5wt% La, and the rest is Al; That is Al 86 Ni 6 Y 4.5 co 2 La 1.5 .

[0040] The particle size range of the aluminum-based amorphous alloy powder is 25-71 μm, and the oxygen content is less than 1000 ppm.

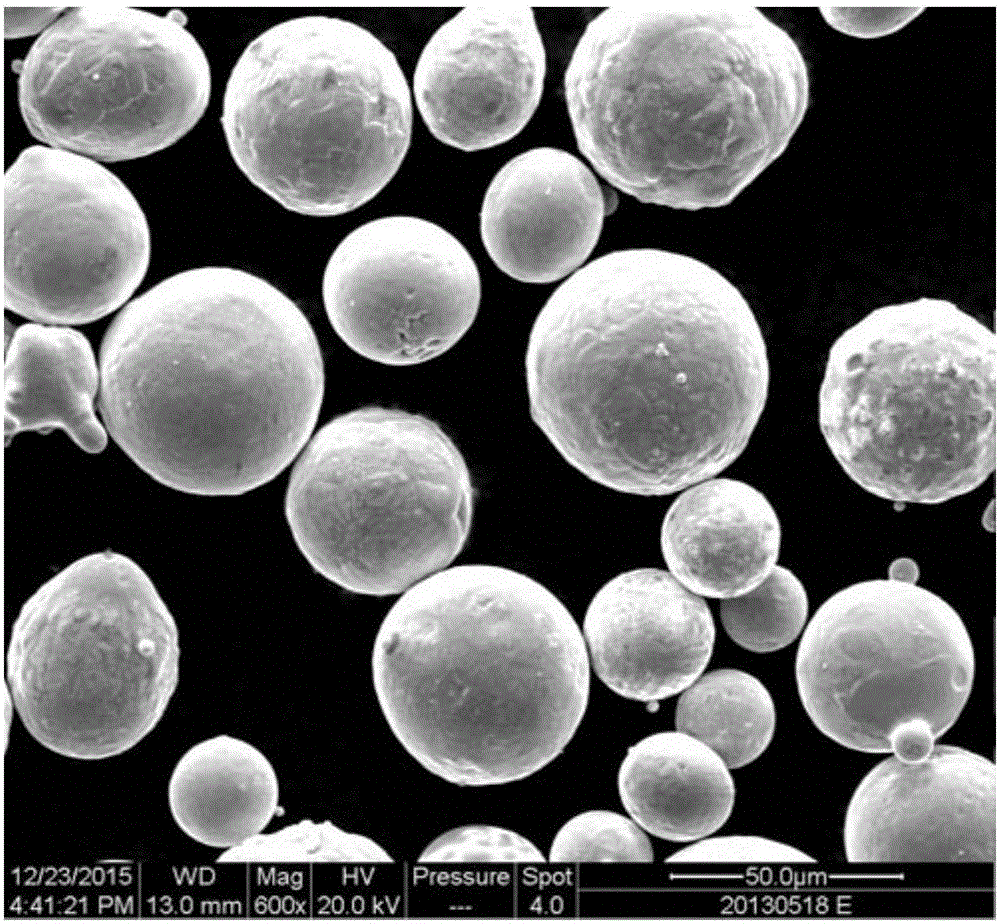

[0041] A Quanta 200 environmental scanning electron microscope (SEM) equipped with an energy spectrum (EDS) accessory was used to observe the structure and morphology of the aluminum-based amorphous alloy powder. The SEM photo is shown in figure 1 .

[0042] Depend on figure 1 It can be seen that the aluminum-based amorphous alloy powder is spherical and has good fluidity, and a small amount of satellite balls are bonded to the surface of some large particles, which helps to increase the packing density of the powder and is suitable for the automatic powder-feeding cladding...

Embodiment 2~ Embodiment 3)

[0089]Each example is basically the same as Example 1, except that the elemental composition of the aluminum-based amorphous alloy powder is shown in Table 2 for details.

[0090]

Embodiment 4~ Embodiment 5)

[0092] Each embodiment is basically the same as embodiment 1, except that the specific process parameters of magnetic field agitation laser cladding forming are shown in Table 3.

[0093]

[0094] According to the methods of Test Examples 1, 3, 4, and 6, the relative properties of the cladding layers prepared in Comparative Example 2 and Examples 2 to 5 were tested, and the results are shown in Tables 1 to 3, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com