Horizontal type biomass-particle heat energy generating and purifying device

A biomass particle and purifier technology, applied in fluid heaters, lighting and heating equipment, blasting equipment, etc., can solve the problems of flue gas escape, unsuitable installation and use, and excessive flue gas concentration, and achieve smooth and smooth operation. , Accurate shape and position datum, the effect of reasonable operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

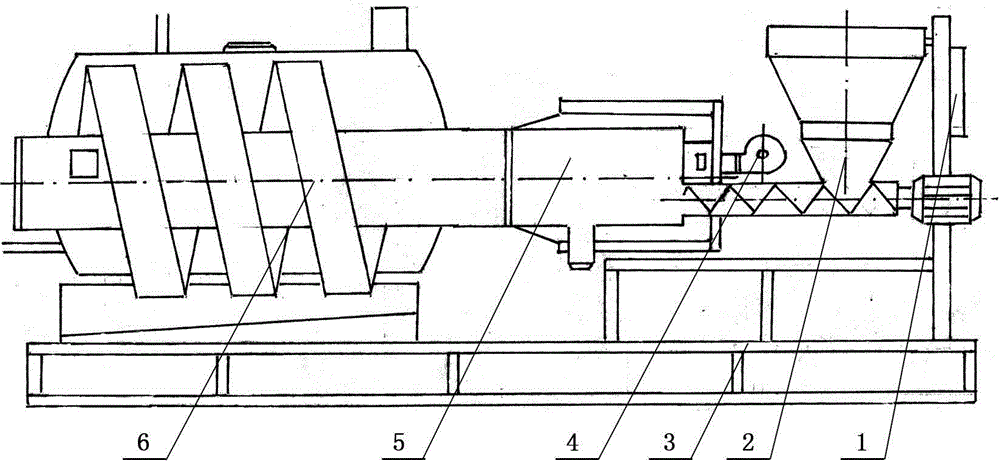

[0053] as attached figure 1 As shown, the horizontal biomass particle heat generation purifier designed in this patent includes a complete machine frame (3), a feeding device (2), an oxygen supply device (4), a particle combustion chamber (5), a separation and purification Heating device (6), manipulation controller (1).

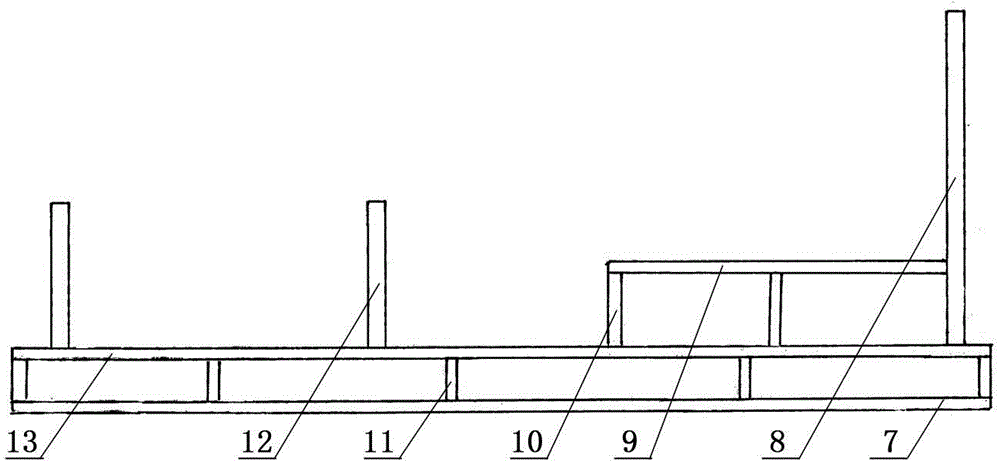

[0054] as attached figure 2 As shown, the complete machine frame (3) includes a base, a door frame, and a bracket. The base is welded and fixed into a chassis of frame structure by bottom beams (7) and cross beams, and is welded and fixed into a base plate of frame structure by base beams (13) and cross beams, and then welded by side columns (11) on both sides. It is connected and fixed as a rigid whole in the form of a three-dimensional grid frame structure. The door frame is composed of left and right two groups of door frames. Each group of door frames includes two front and rear door posts (12) and arc-shaped joists. The lower ends of each group of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com