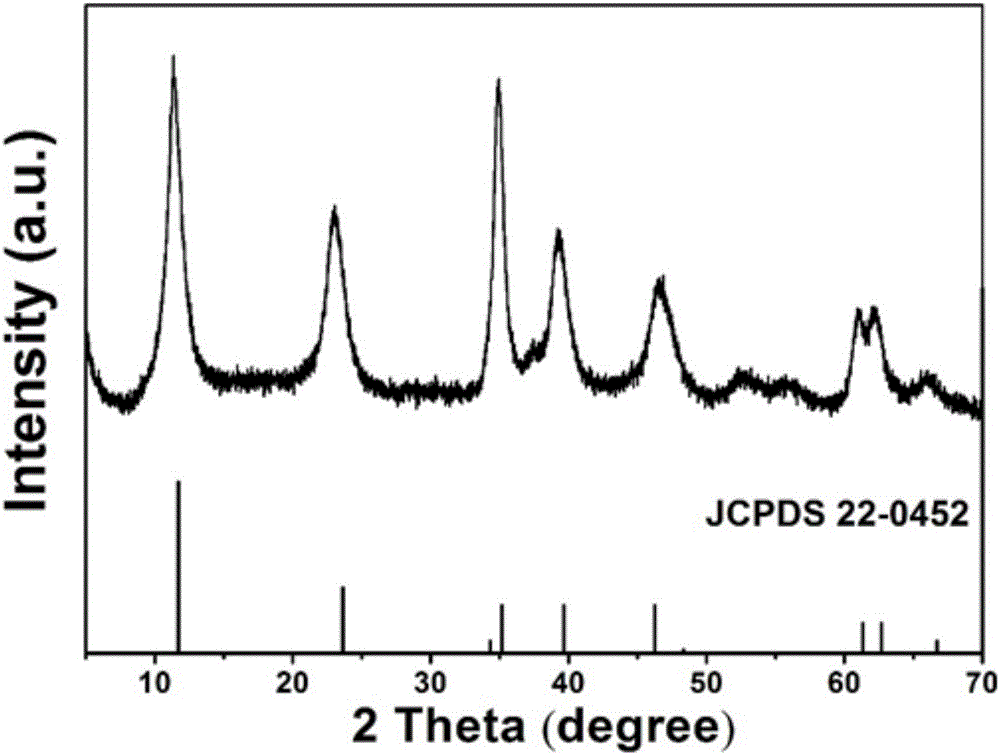

Preparation method of supercapacitor taking laminar nickel aluminum and hydrotalcite nanomaterial as positive electrode

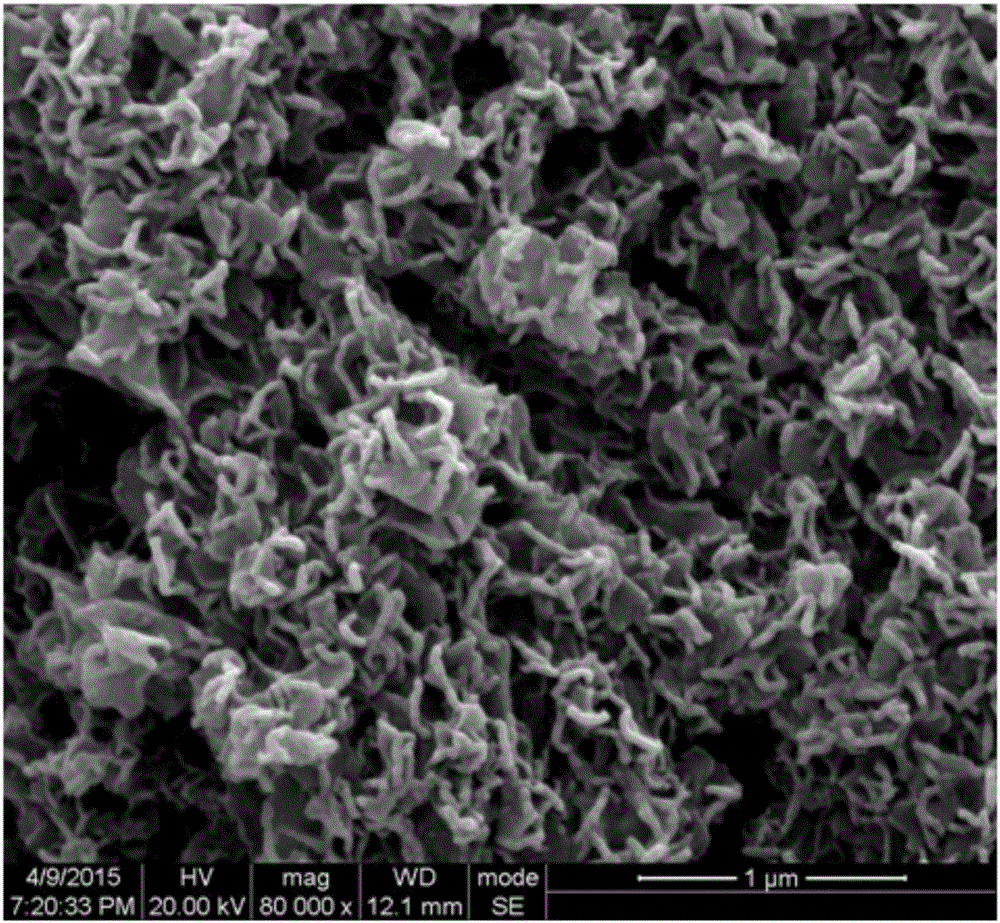

A nickel-aluminum hydrotalcite and supercapacitor technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, nanotechnology, etc., can solve the problems of low energy density of supercapacitors, and achieve stable structure, large specific surface area, and high power The effect of increasing density and energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Disperse 250g of aluminum isopropoxide in 5L of water, stir at 70°C for 12h, then add dropwise HNO with a concentration of 3mol / L 3 Adjust the pH value of the solution to 3, continue to stir, cool the solution system to room temperature, and obtain the AlOOH sol after the water evaporates; grind 250g of the dried AlOOH sol, add 5L of water to stir for 12h, and then reflux for 12h to obtain the AlOOH sol precursor body;

[0029] (2) Take 5L of the AlOOH sol precursor obtained in step (1), and drop Ni(NO 3 ) 2 Solution 0.5L, after stirring, add urea 50g, hydrothermal reaction at 100°C for 24h, filter the product after the reaction is completed, wash the product alternately with water and ethanol, dry the obtained product at 80°C for 12h, and obtain lamellar nickel-aluminum water Talc nanomaterials;

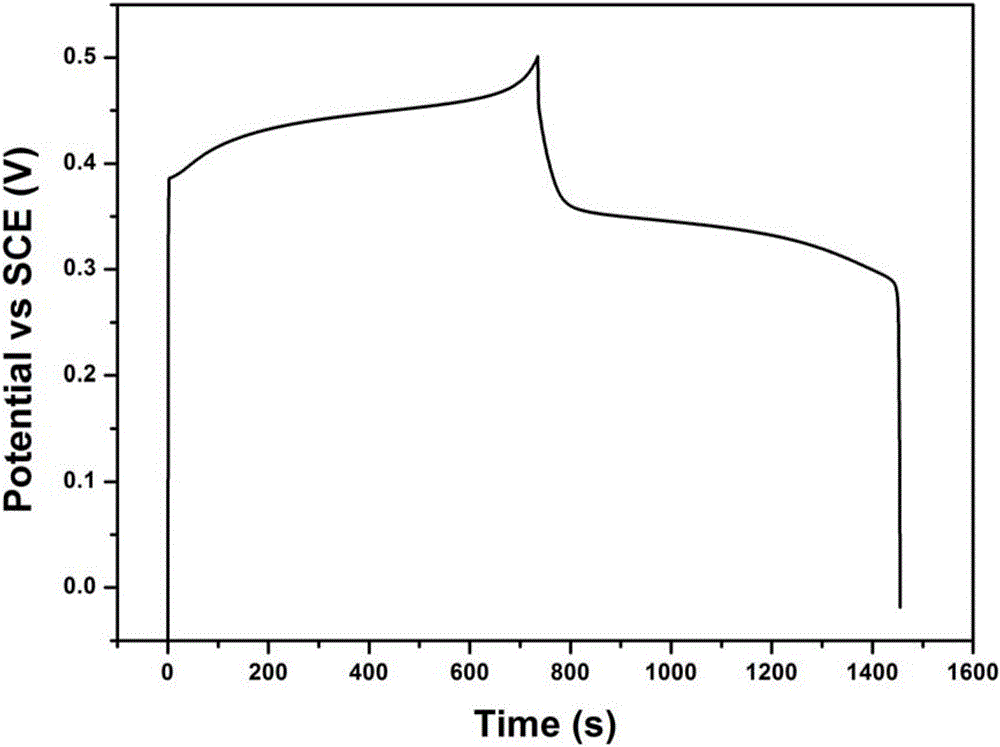

[0030] (3) the lamellar nickel-aluminum hydrotalcite nanomaterial obtained in step (2) is the positive electrode material, acetylene black is the conductive agent, and...

Embodiment 2

[0036] (1) Disperse 250g of aluminum isopropoxide in 5L of water, stir at 50°C for 24h, then add dropwise HNO with a concentration of 1mol / L 3 Adjust the pH value of the solution to 6, continue to stir, cool the solution system to room temperature, and obtain the AlOOH sol after the water evaporates; grind 250g of the dried AlOOH sol, add 10L of water to stir for 12h, and then reflux for 12h to obtain the AlOOH sol precursor body;

[0037] (2) Take 10L of the AlOOH sol precursor obtained in step (1), and drop Ni(NO 3 ) 2 Solution 1L, after stirring, add urea 70g, hydrothermal reaction at 200°C for 18h, filter the product after the reaction is complete, wash the product alternately with water and ethanol, dry the obtained product at 80°C for 12h, and obtain lamellar nickel-aluminum hydrotalcite nanomaterials;

[0038] (3) the lamellar nickel-aluminum hydrotalcite nanomaterial obtained in step (2) is the positive electrode material, acetylene black is the conductive agent, an...

Embodiment 3

[0043] (1) Disperse 250g of aluminum isopropoxide in 5L of water, stir at 90°C for 5h, then add dropwise HNO with a concentration of 5mol / L 3 Adjust the pH value of the solution to 4, continue to stir, cool the solution system to room temperature, and obtain the AlOOH sol after the water evaporates; grind 250g of the dried AlOOH sol, add 25L of water to stir for 12h, and then reflux for 12h to obtain the AlOOH sol precursor body;

[0044] (2) Take 25L of the AlOOH sol precursor obtained in step (1), and drop Ni(NO 3 ) 2 Solution 2.5L, after stirring, add 100g of urea, hydrothermal reaction at 150°C for 22h, filter the product after the reaction is completed, wash the product alternately with water and ethanol, dry the obtained product at 100°C for 8h, and obtain lamellar nickel-aluminum water Talc nanomaterials;

[0045] (3) the lamellar nickel-aluminum hydrotalcite nanomaterial obtained in step (2) is the positive electrode material, acetylene black is the conductive agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com