Proton exchange membrane fuel cell membrane electrode electrocatalyst and preparation method thereof

A technology for fuel cell membranes and proton exchange membranes, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of electrocatalyst performance degradation, insufficient dispersion, poor electrode performance, etc., and achieve improved utilization, particle size, etc. Small size and good electrochemical reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

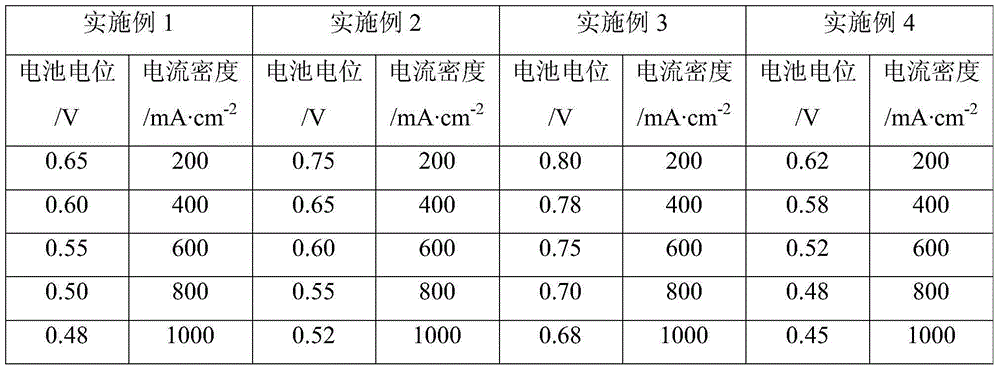

Embodiment 1

[0022] Weigh 200mg of graphene oxide powder and place it in 300mL of propylene glycol for ultrasonic vibration to obtain a uniformly mixed graphene oxide alcohol solution; weigh 2mL of 0.05mol / L chloroplatinic acid, place it in 30mL of propylene glycol, stir and mix evenly to obtain chloroplatinic acid Alcohol solution; mix the above two solutions, add 5% NaOH solution under stirring, adjust pH = 10, stir for 30 minutes, put it into a microwave reactor, microwave power 200W, temperature 180°C, heat for 5 minutes, after the reaction is complete, cool to room temperature; the reaction solution was vacuum filtered, the filter cake was washed alternately with absolute ethanol and deionized water, and washed three times respectively until the pH of the filtrate = 7, and then dried in a vacuum oven at 80°C for 3 hours to constant weight to obtain graphite oxide A Pt / graphene electrocatalyst with alkene as a carrier and Pt as an active component, and the mass percentage of Pt is about...

Embodiment 2

[0024] Weigh 200mg of graphene oxide powder and place it in 300mL of propylene glycol for ultrasonic vibration to obtain a uniformly mixed graphene oxide alcohol solution; weigh 3mL of 0.05mol / L chloroplatinic acid, place it in 30mL of propylene glycol, stir and mix evenly to obtain chloroplatinic acid Alcohol solution; mix the above two solutions, add 5% NaOH solution under stirring, adjust pH = 10, stir for 30 minutes, put it into a microwave reactor, microwave power 200W, temperature 180°C, heat for 5 minutes, after the reaction is complete, cool to room temperature; the reaction solution was vacuum filtered, the filter cake was washed alternately with absolute ethanol and deionized water, and washed three times respectively until the pH of the filtrate = 7, and then dried in a vacuum oven at 80°C for 3 hours to constant weight to obtain graphite oxide A Pt / graphene electrocatalyst with alkene as a carrier and Pt as an active component, and the mass percentage of Pt is about...

Embodiment 3

[0026] Weigh 350mg of graphene oxide powder and place it in 400mL of ethylene glycol for ultrasonic vibration to obtain a uniformly mixed graphene oxide alcohol solution; measure 6mL of 0.06mol / L chloroplatinic acid, place it in 20mL of ethylene glycol, and stir evenly Obtain chloroplatinic acid alcohol solution; mix the above two solutions, add 5% KOH solution under stirring, adjust pH = 12, stir for 20 minutes, then put it into a microwave reactor, microwave power 180W, temperature 120°C, heat for 8 minutes, and the reaction is complete , cooled to room temperature; the reaction solution was vacuum filtered, and the filter cake was washed alternately with acetone and deionized water for 5 times until the filtrate pH=7, and then dried in a vacuum oven at 60°C for 5 hours to constant weight to obtain graphene oxide A Pt / graphene nanometer electrocatalyst with Pt as a carrier and an active component; the mass percentage of Pt is about 20%. The particle size of the Pt / graphene e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com