Method for preparing indium oxide nanoparticle of porous structure

A porous structure and nanoparticle technology, which is applied in the field of preparation of indium oxide nanoparticles, can solve the problems of complicated preparation methods, high production costs, and industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

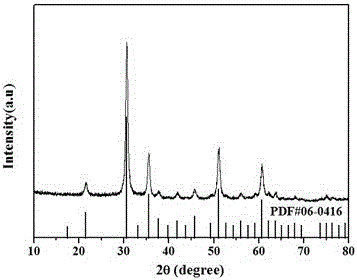

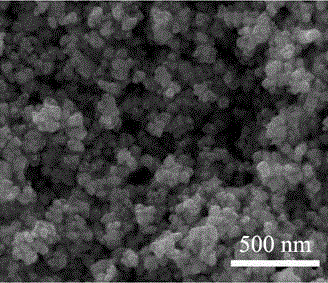

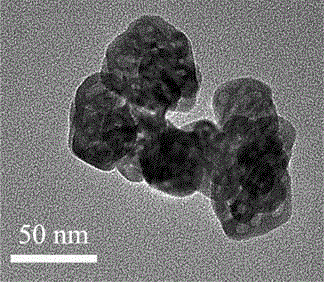

Embodiment 1

[0016] (1) Weigh a certain amount of indium chloride and dodecylamine, dissolve them in absolute ethanol, the concentration of indium chloride is 0.025 mol / L, the concentration of dodecylamine is 0.025 mol / L, and control the The molar ratio of indium to dodecylamine is 1:1;

[0017] (2) Move the mixed solution obtained in step (1) to a hydrothermal reaction kettle lined with polytetrafluoroethylene, conduct a hydrothermal reaction at a temperature of 170°C for 8 hours, and then use the product after the hydrothermal reaction The centrifuge is used for solid-liquid separation, and the obtained solid product is washed several times with deionized water and ethanol;

[0018] (3) Place the solid product obtained in step (2) in a drying oven, dry at 60°C for 24 hours, then put it in an alumina crucible and put it in a muffle furnace, and heat-treat it at 400°C for 3 hours to obtain indium oxide with a porous structure Powder.

Embodiment 2

[0020] (1) Weigh a certain amount of indium chloride and dodecylamine, dissolve them in absolute ethanol, in which the concentration of indium chloride and dodecylamine is 0.028 mol / L, and the concentration of dodecylamine is 0.028 mol / L. The molar ratio of indium to dodecylamine is 1:1;

[0021] (2) Move the mixed solution obtained in step (1) to a hydrothermal reaction kettle lined with polytetrafluoroethylene, and conduct a hydrothermal reaction at a temperature of 180°C for 12 hours, and then use the product after the hydrothermal reaction The centrifuge is used for solid-liquid separation, and the obtained solid product is washed several times with deionized water and ethanol;

[0022] (3) Place the solid product obtained in step (2) in a drying oven, dry at 60°C for 24 hours, then put it in an alumina crucible and put it in a muffle furnace, and heat-treat it at 400°C for 3 hours to obtain indium oxide with a porous structure Powder.

Embodiment 3

[0024] (1) Weigh a certain amount of indium chloride and dodecylamine, dissolve them in absolute ethanol, the concentration of indium chloride is 0.028 mol / L, the concentration of dodecylamine is 0.056 mol / L, and control the The molar ratio of indium to dodecylamine is 1:2;

[0025] (2) Move the mixed solution obtained in step (1) to a hydrothermal reaction kettle lined with polytetrafluoroethylene, and conduct a hydrothermal reaction at a temperature of 180°C for 12 hours, and then use the product after the hydrothermal reaction The centrifuge is used for solid-liquid separation, and the obtained solid product is washed several times with deionized water and ethanol;

[0026] (3) Place the solid product obtained in step (2) in a drying oven, dry at 60°C for 24 hours, then put it in an alumina crucible and put it in a muffle furnace, and heat-treat it at 400°C for 3 hours to obtain indium oxide with a porous structure Powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com