Pulse type vacuum atomization and infiltration promotion equipment and method for fruits and vegetables

A pulsed, fruit and vegetable technology, applied in fruit and vegetable preservation, food preservation, food science and other directions, can solve the problems of affecting the preservation effect, environmental pollution, high residual preservatives, etc., to improve the preservation effect, reduce excessive pollution, and increase use. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: Take Agaricus bisporus as an example.

[0039] (1) Raw material pretreatment: Fresh Agaricus bisporus is first washed with running water after harvesting to remove dust, sediment and other sundries on the surface. Pre-cool at 2±1°C for 24 hours, and choose Agaricus bisporus with uniform size, no umbrella opening, no insect damage and mechanical damage, and the diameter of the mushroom cap is 3-4cm for the test.

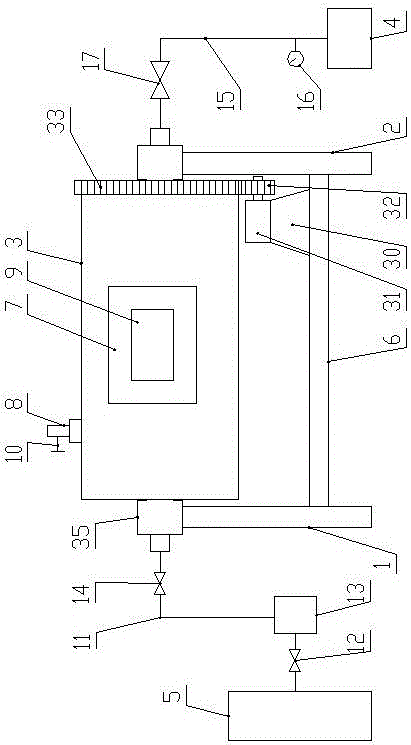

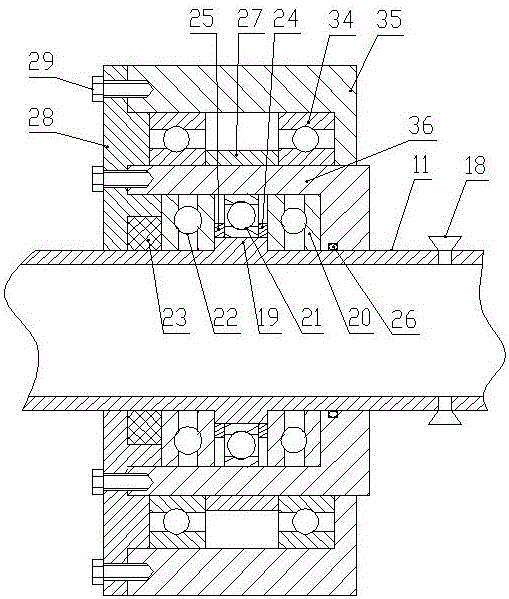

[0040] (2) Vacuum atomization to enhance infiltration: firstly open the feeding door 7, put 100 Agaricus bisporus in each group into the atomized infiltration enhancer tank 3, close the manual valve 10 on the intake pipe 8, open the third solenoid valve 17, Evacuate the inside of the atomized permeation enhancement tank 3 to a vacuum of 0.04MPa and keep it for 10s. Then open the first solenoid valve 12 and the second solenoid valve 14, set the pulse time on the pulse intelligent control system panel as 10s, and the interval is 10s, then start the...

Embodiment 2

[0042] Embodiment 2: In this implementation, take Chinese toon as example.

[0043] (1) Raw material pretreatment: After fresh Chinese toon is harvested, it is first washed with running water to remove dust, sediment and other sundries on the surface. After washing, it is picked up and placed in a drain net to control water. Pre-cool at 2±1°C for 24 hours, select Toona sinensis branches with a relatively consistent maturity, no pests and mechanical damage, and a length of about 15cm for the test.

[0044] (2) Vacuum atomization to enhance penetration: first open the feeding door 7, put each group of 2kg Chinese toon into the atomization enhancement tank 3, close the manual valve 10 on the intake pipe 8, open the third solenoid valve 17, and pump to vacuum temperature to 0.03 MPa, hold for 10s. Then open the first solenoid valve 12 and the second solenoid valve 14, and set the pulse time to be 10s and the interval to be 10s on the pulse intelligent control system panel. Then ...

Embodiment 3

[0046] Embodiment 3: In this implementation, take Apple as an example.

[0047] (1) Raw material pretreatment: Fresh apples are first washed with running water after harvesting to remove dust, silt and other sundries on the surface. Pre-cool at 2±1°C for 24 hours, and select apples with relatively consistent size and maturity, no pests and mechanical damage, for the test.

[0048] (2) Vacuum atomization to enhance penetration: open the feeding door 7, put 50 apples in each group into the atomization enhancement tank 3, close the manual valve 10 on the intake pipe 8, open the third solenoid valve 17, and pump to vacuum temperature to 0.05 MPa, keep for 1min. Then open the first electromagnetic valve 12 and the second electromagnetic valve 14, set the pulse time on the pulse intelligent control system panel as 1min, and the interval is 30s, then start the pulse intelligent control liquid pump 13, and carry out the vacuum atomization of the preservative to the fruits and vegetab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com