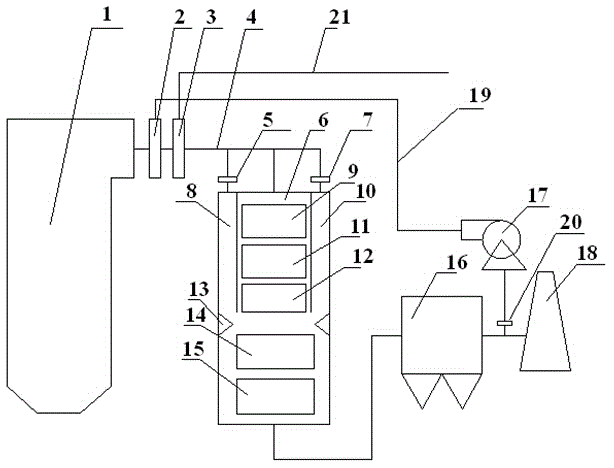

SNCR-SCR combined flue gas denitrification system

A flue gas and denitrification technology, applied in the field of flue gas denitration system, can solve the problems of affecting the denitration efficiency of SNCR and SCR, large fluctuation of boiler flue gas temperature, and shortening of catalyst life, etc., to facilitate transformation, reduce energy consumption and reduce emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be understood that the above-mentioned drawings are not true to scale, but merely schematic diagrams illustrating various preferred features illustrating the basic principles of the invention. The design features disclosed in the present invention, such as size, orientation, orientation and shape are determined according to the specific application and use environment. In addition, in the following description, terms such as "front", "rear", "before", "rear", "front end", "rear end" and other descriptions are defined relative to the flow direction of smoke.

[0026] Combine below figure 1 Specific examples of the present invention will be described in detail.

[0027] A boiler in a thermal power plant is used to burn coal, and the boiler may be, for example, a fluidized bed boiler. The flue gas in the coal combustion enters the horizontal flue 4 from the outlet of the furnace 1 . In the horizontal flue 4, the ammonia injection grid 3 is vertically arranged,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com