Energy-saving nanofiltration membrane for water purification system and preparation method thereof

A water purification system and nanofiltration membrane technology, which is applied in the field of water treatment, can solve problems such as ineffective removal and inability to ensure drinking water safety, and achieve the effect of avoiding osmotic resistance, avoiding a large increase, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

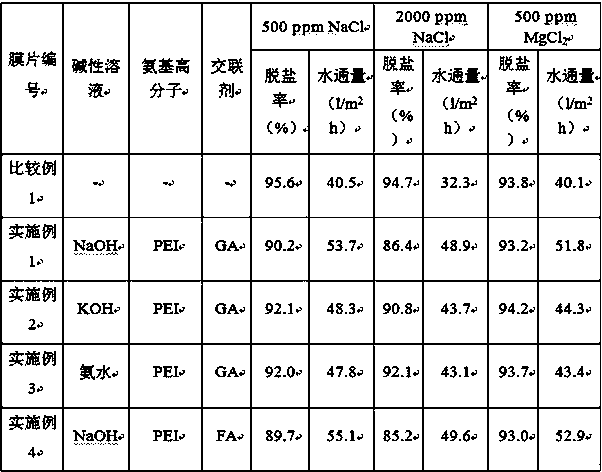

Embodiment 1

[0030] A dense nanofiltration membrane with a non-woven fabric layer, a polysulfone support layer and a polyamide layer is prepared according to a conventional method.

[0031] First, the polysulfone microporous membrane composed of non-woven fabric and polysulfone support layer was immersed in an aqueous solution containing 1 wt% m-phenylenediamine, and the excess solution on the surface was removed with a rubber roller. The organic phase solution of 1 wt% trimesoyl chloride was contacted for 1 minute, and heat-treated in an oven at 70 °C for 5 minutes to obtain a dense nanofiltration membrane.

[0032] Then soak the dense nanofiltration membrane in an aqueous NaOH solution with a mass fraction of 0.5%, take it out after 5 minutes, rinse it, and contact it with an aqueous solution containing polyethyleneimine for 1 minute, remove the excess aqueous solution on the surface, and use a mass fraction of 1.0% The glutaraldehyde aqueous solution was cross-linked and heat-treated at...

Embodiment 2

[0035] A dense nanofiltration membrane with a non-woven fabric layer, a polysulfone support layer and a polyamide layer is prepared according to a conventional method.

[0036]First, the polysulfone microporous membrane composed of non-woven fabric and polysulfone support layer was immersed in an aqueous solution containing 1 wt% m-phenylenediamine, and the excess solution on the surface was removed with a rubber roller. The organic phase solution of 1 wt% trimesoyl chloride was contacted for 1 minute, and heat-treated in an oven at 70 °C for 5 minutes to obtain a dense nanofiltration membrane.

[0037] Then soak the dense nanofiltration membrane in a KOH aqueous solution with a mass fraction of 0.5%, take it out after 5 minutes, rinse it, and contact it with an aqueous solution containing polyethyleneimine for 1 minute, remove the excess aqueous solution on the surface and use a mass fraction of 1.0% The glutaraldehyde aqueous solution was cross-linked and heat-treated at 80°...

Embodiment 3

[0040] A dense nanofiltration membrane with a non-woven fabric layer, a polysulfone support layer and a polyamide layer is prepared according to a conventional method.

[0041] First, the polysulfone microporous membrane composed of non-woven fabric and polysulfone support layer was immersed in an aqueous solution containing 1 wt% m-phenylenediamine, and the excess solution on the surface was removed with a rubber roller. The organic phase solution of 1 wt% trimesoyl chloride was contacted for 1 minute, and heat-treated in an oven at 70 °C for 5 minutes to obtain a dense nanofiltration membrane.

[0042] Then soak the dense nanofiltration membrane in an ammonia solution with a mass fraction of 0.5%, take it out after 5 minutes, rinse it, and contact it with an aqueous solution containing polyethyleneimine for 1 minute, remove the excess aqueous solution on the surface, and use a mass fraction of 1.0% The glutaraldehyde aqueous solution was cross-linked and heat-treated at 80°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com