Method for purifying ulinastatin on basis of ion exchange resin

The technology of ion exchange resin and ulinastatin, which is applied in the field of medicine, can solve the problems of influence on the yield of ulinastatin, complicated purification process, etc., and achieve the effects of increasing molecular weight cut off, simple purification process and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

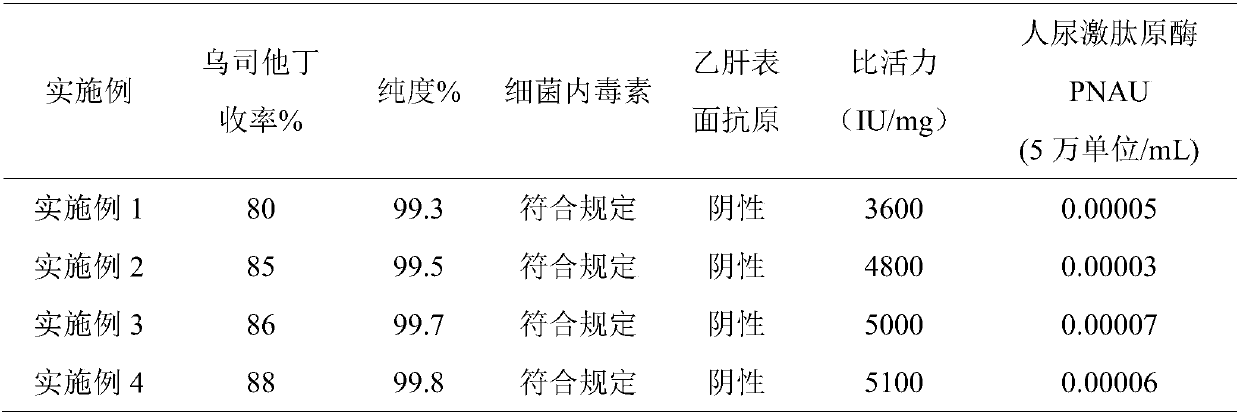

Examples

Embodiment 1

[0041] 1) Take 1 ton of clarified urine, adjust the pH to 6, filter it with gauze, add 8 kg of chitosan-chitin mixture (chitosan: chitin = 3:1) to the filtrate while stirring, adjust the pH to 4, Stir until the adsorption is complete, filter, discard the urine, wash with water to remove residual urine and impurities until clarification; stir and wash chitosan-chitin with ammonia water, and filter to obtain the filtrate; add ammonium sulfate to the filtrate for salting out, stir to dissolve, and static Place, precipitate, and obtain the crude product of ulinastatin after filtering the obtained solid and drying it;

[0042]2) Add sodium acetate-acetic acid buffer solution of pH=5 to the ulinastatin crude product until completely dissolved, continue to add sodium alginate (molecular weight 20,000), stirring, leaving standstill, centrifuging to obtain the lower sediment 1, adding ammonium sulfate buffer solution to the sediment 1 to make pH=6, ultrafiltration to obtain the retenta...

Embodiment 2

[0048] 1) Take 1 ton of clarified urine, adjust the pH to 6.5, filter it with gauze, add 12 kg of chitosan-chitin mixture (chitosan: chitin = 8:1) to the filtrate while stirring, adjust the pH to 5, Stir until the adsorption is complete, filter, discard the urine, wash with water to remove residual urine and impurities until clarification; stir and wash chitosan-chitin with ammonia water, and filter to obtain the filtrate; add ammonium sulfate to the filtrate for salting out, stir to dissolve, and static Place, precipitate, and obtain the crude product of ulinastatin after filtering the obtained solid and drying it;

[0049] 2) Add sodium acetate-acetic acid buffer solution with pH=5.5 to the crude ulinastatin until completely dissolved, and continue to add sodium alginate (molecular weight 50,000), stirring, standing, and centrifugation to obtain the lower sediment 1, adding ammonium sulfate buffer solution to the sediment 1 to make pH=6.5, and ultrafiltration to obtain the r...

Embodiment 3

[0055] 1) Take 1 ton of clarified urine, adjust the pH to 6.5, filter it with gauze, add 12 kg of chitosan-chitin mixture (chitosan: chitin = 5:1) to the filtrate while stirring, adjust the pH to 4, Stir until the adsorption is complete, filter, discard the urine, wash with water to remove residual urine and impurities until clarification; stir and wash chitosan-chitin with ammonia water, and filter to obtain the filtrate; add ammonium sulfate to the filtrate for salting out, stir to dissolve, and static Place, precipitate, and obtain the crude product of ulinastatin after filtering the obtained solid and drying it;

[0056] 2) Add sodium acetate-acetic acid buffer solution with pH=5 to the crude product of ulinastatin until completely dissolved to obtain mixed solution 1;

[0057] Adjust the pH=6 of the mixed solution 1, pass it through the anion exchange resin AmberliteIRA400 at a speed of 120mL / min, and then use NaH with pH=6 2 PO 4 -Na 2 HPO 4 The mixed solution of buf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com