High-strength and hydrophilic polysulfone hollow fiber ultrafiltration membrane

An ultrafiltration membrane, high-strength technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of complex spinning process, low strength of hollow fiber membrane, low hydrophilicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

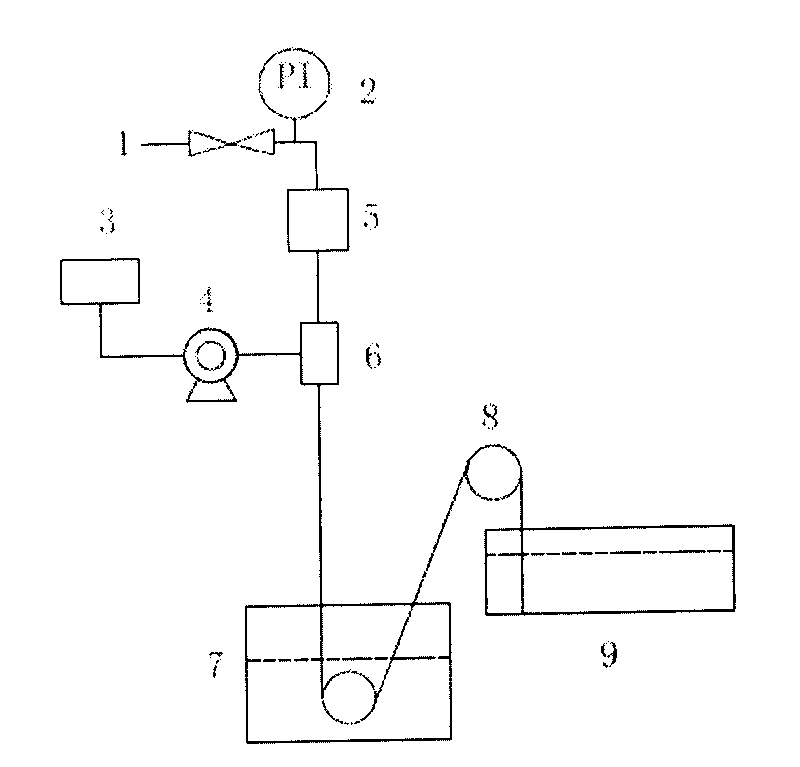

[0054] The formula of the casting solution is: PES 18%, PVP 8%, PEG600 2%, acetone 1%, and the rest is N,N-dimethylacetamide (DMAC). Add various raw materials into a three-necked flask with a stirrer and a thermometer, swell at 40°C for 2 hours, then raise the temperature to 70°C and continue stirring for 20 hours to prepare a uniform and stable polymer mixed solution, and then carry out Filtration, defoaming, and the prepared spinning stock solution was left to stand for at least 24 hours before use.

[0055] The spinning conditions are shown in Table 2. The spinneret is a three-hole spinneret. The extrusion speed of spinning solution is 17g·min -1 , the flow rate of core fluid is 5g·min -1 ; After a 5cm dry spinning process, the nascent hollow fiber undergoes phase inversion in a coagulation bath at 45°C to form a hollow fiber membrane; then it is collected by the godet wheel at a speed of 2.7r·min -1 .

[0056] The operating condition of table 2 embodiment one

[0057...

Embodiment 1

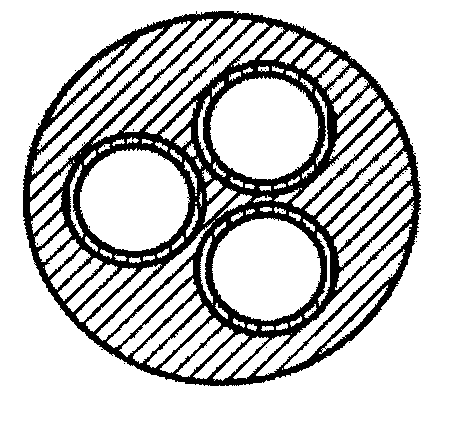

[0059] The cross-sectional structure of embodiment 1 gained three-hole membrane sees attached Figure 4 .

[0060] The main performance parameters of the membrane are: the pure water flux of the membrane is 94L m at 0.1MPa -2 h -1 , the rejection rate of polyethylene glycol with a molecular weight of 20kD is over 90%, the contact angle is 64°, and the breaking force and bursting strength are respectively 7.85N and 0.50MPa.

Embodiment 2

[0070] The casting solution formula is: PES 14%, PVP 8%, FeCl 3 3%, lithium chloride (LiCl) 4%, PEG6002%, soil temperature 20 2%, and the rest is N, N-dimethylacetamide (DMAC). A three-hole spinneret was used, and the spinning conditions and membrane performance parameters are shown in Table 4.

[0071] Spinning conditions and membrane performance parameters of the second embodiment of table 4

[0072]

[0073] Compared with Example 1, the feature of Example 2 is that under the condition of very low polyethersulfone content, the method of adding lithium chloride is used to change the viscosity of the casting solution and improve the spinnability of the casting solution; at the same time, adding FeCl 3 , through FeCl 3 The complexation reaction with PVP modifies the polyethersulfone membrane to improve the hydrophilic performance of the membrane. Surfactant TWen 20 can increase FeCl 3 solubility.

[0074] It can be seen from Table 4 that the pure water flux of the memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com