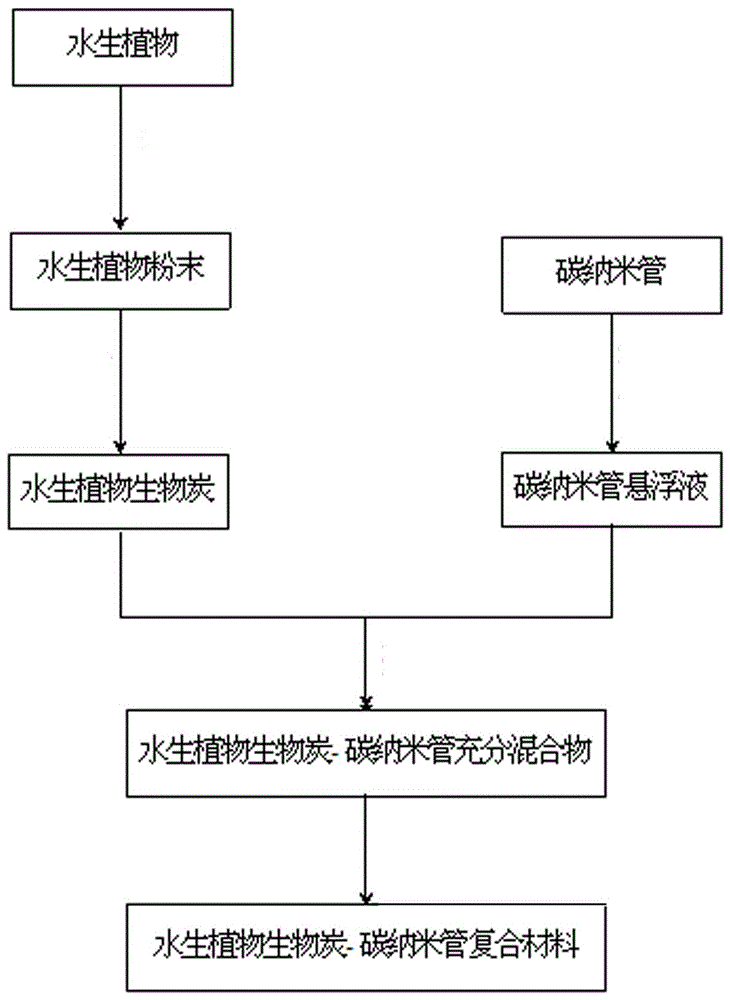

Preparation method and application of aquatic plant charcoal-carbon nanotube composite material

A technology of aquatic plants and carbon nanotubes, applied in water pollutants, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as poor adsorption capacity, achieve high adsorption performance, reduce transportation costs, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

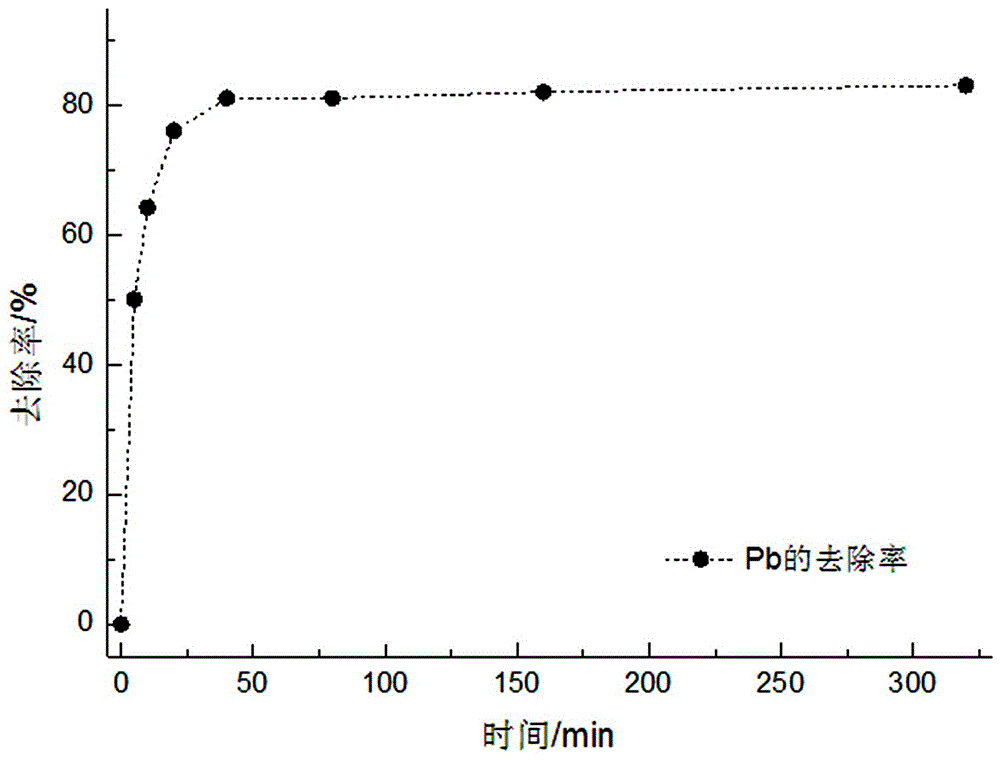

Examples

Embodiment Al

[0034] (1) Naturally air-dry the reeds so that the internal moisture content is lower than 10%, and then crush them through a 100-mesh sieve to obtain reed powder;

[0035] (2) Weigh the reed powder described in step (1), put the powder in a box-type atmosphere furnace, and pass nitrogen gas into the furnace, the nitrogen flow rate is 400 mL / min; the heating rate is controlled at 10 °C / min, and the temperature is programmed to To 500°C, keep the final temperature and continue pyrolysis for 60 minutes; after the pyrolysis process is over, reed biochar can be obtained;

[0036] (3) The carbon nanotube suspension was prepared by adding 2 g of carbon nanotube powder prepared in advance into 100 mL of deionized water;

[0037] (4) The carbon nanotube suspension described in step (3) is ultrasonically treated with an ultrasonic homogenizer, the output frequency is 20 kHz per hour, the pulse interval is 15 min, and the ultrasonic time is 1 h;

[0038] (5) Weigh 1 g of reed biochar d...

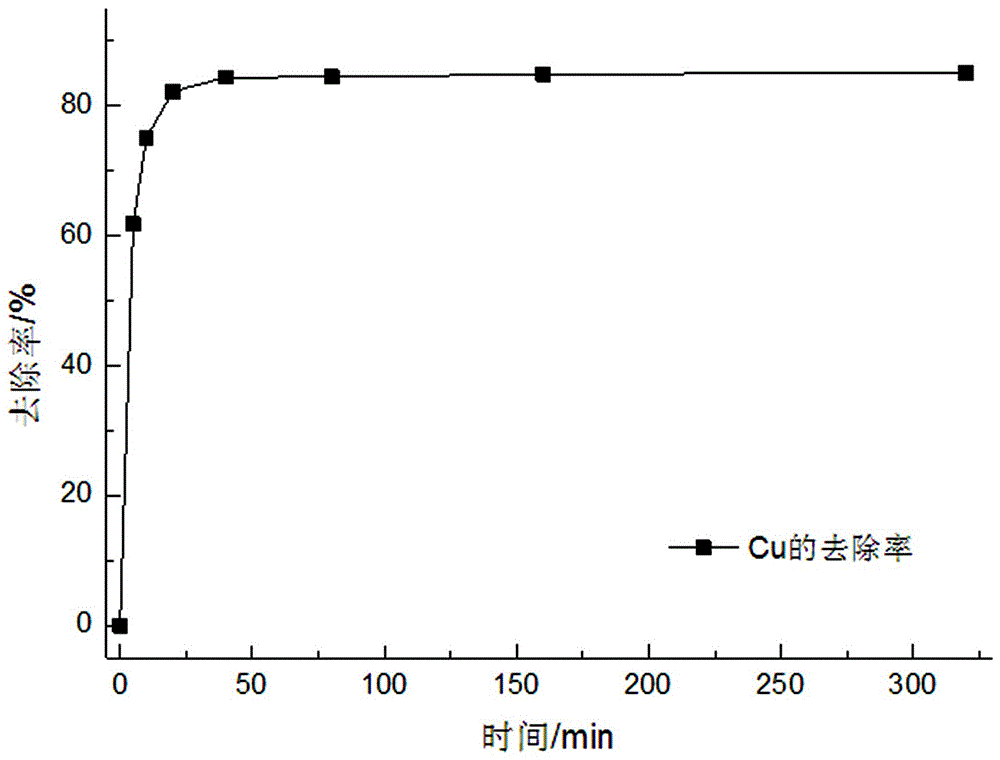

Embodiment A2

[0041] (1) Naturally air-dry the cattail so that the internal moisture content is lower than 10%, and then crush it through a 100-mesh sieve to obtain the cattail powder;

[0042] (2) Weigh the cattail powder described in step (1), place the powder in a box-type atmosphere furnace, and feed nitrogen into the furnace at a nitrogen flow rate of 400 mL / min; control the heating rate at 10 °C / min, and program the temperature to To 500°C, keep the final temperature and continue pyrolysis for 60 minutes; after the pyrolysis process is over, Typha biochar is obtained;

[0043] (3) The carbon nanotube suspension was prepared by adding 2 g of carbon nanotube powder prepared in advance into 100 mL of deionized water;

[0044] (4) The carbon nanotube suspension described in step (3) is ultrasonically treated with an ultrasonic homogenizer, the output frequency is 20 kHz per hour, the pulse interval is 15 min, and the ultrasonic time is 1 h;

[0045] (5) Weigh 1 g of Typha biochar describ...

Embodiment A3

[0048] (1) Naturally air-dry Zizania so that the internal moisture content is lower than 10%, and then crush it through a 100-mesh sieve to obtain Zizania powder;

[0049] (2) Weigh the asparagus powder described in step (1), put the powder in a box-type atmosphere furnace, and pass nitrogen gas into the furnace, the nitrogen flow rate is 400 mL / min; the heating rate is controlled at 10 °C / min, the program Raise the temperature to 500°C, and keep the final temperature for pyrolysis for 60 minutes; after the pyrolysis process is over, the Zizinia japonica biochar is obtained;

[0050] (3) The carbon nanotube suspension was prepared by adding 2 g of carbon nanotube powder prepared in advance into 100 mL of deionized water;

[0051] (4) The carbon nanotube suspension described in step (3) is ultrasonically treated with an ultrasonic homogenizer, the output frequency is 20 kHz per hour, the pulse interval is 15 min, and the ultrasonic time is 1 h;

[0052] (5) Weigh 1 g of Zizani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com