Sulfur-doped carbon material loading noble-metal catalyst and application thereof

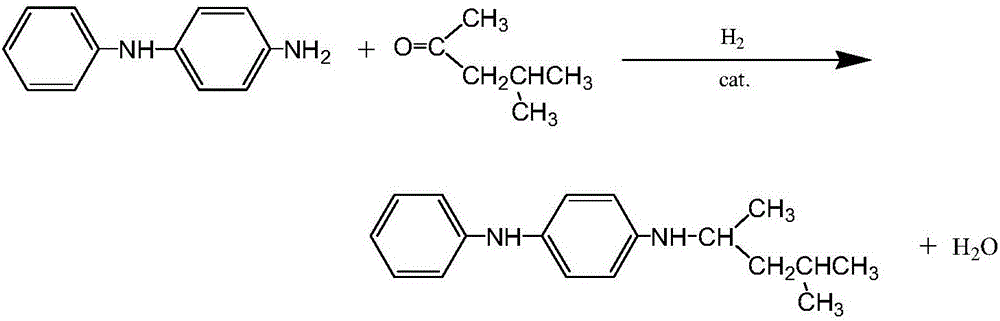

A technology of noble metal catalysts and carbon materials, which is applied in the direction of physical/chemical process catalysts, organic chemistry, amino compound preparation, etc., can solve the problems of reducing the purity and quality of hydrogenation products, complex operations, etc., to avoid sulfur loss, high activity, highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Weigh 10g of activated carbon, the particle size of activated carbon is 150 mesh, and the specific surface area is 1400m 2 / g, the ash content is 0.5wt%, it is mixed evenly with 0.7g elemental sulfur, and treated at 1000°C for 5h under nitrogen atmosphere to obtain sulfur-doped activated carbon. Then the above-mentioned sulfur-doped activated carbon was prepared into a slurry at a temperature of 70° C. in 100 ml of deionized water, and 10 ml of H 2PdCl 4 solution (the Pd content is 0.04g / ml), stirred for 2.5h; the pH value of the solution was adjusted to 8 with 10wt% NaOH solution, and the temperature was lowered to room temperature, filtered, and the filter cake was washed to neutrality with deionized water; The filter cake was configured into a slurry at 70°C, 2ml of 85% hydrazine hydrate solution was added dropwise, stirred for 2 hours, filtered, the filter cake was washed with deionized water until neutral, and vacuum-dried at 100°C to obtain sulfur-doped activated...

Embodiment 2

[0042] Weigh 10g of activated carbon, the particle size of activated carbon is 300 mesh, and the specific surface area is 1200m 2 / g, ash content 0.3wt%, put it in H 2 S / Ar mixed gas (volume ratio 1 / 10) was treated at 800° C. for 10 h at a mixed gas flow rate of 2 L / h to obtain sulfur-doped activated carbon. The above-mentioned sulfur-doped activated carbon was prepared into a slurry at a temperature of 60°C in 100ml of deionized water, and 8ml of H 2 PtCl 6 solution (Pt content is 0.05g / ml), stirred for 2h; the pH value of the solution was adjusted to 8.5 with 10wt% KOH solution, and the temperature was lowered to room temperature, filtered, and the filter cake was washed to neutrality with deionized water; The cake was prepared into a slurry at 60°C, 10ml of formaldehyde was added dropwise, stirred for 2 hours, filtered, the filter cake was washed with deionized water until neutral, and dried in vacuum at 90°C to obtain a platinum catalyst supported on sulfur-doped activat...

Embodiment 3

[0044] Weigh 10g of activated carbon, the particle size of activated carbon is 400 mesh, and the specific surface area is 1600m 2 / g, the ash content is 1.0wt%, it is mixed with 4g of thiophene evenly, and treated at 600°C for 3h under helium atmosphere to obtain sulfur-doped activated carbon. The above sulfur-doped activated carbon was prepared into a slurry at a temperature of 40°C in 100ml of deionized water, and 10ml of Pd(NO 3 ) 2 solution (with a Pd content of 0.05g / ml), stirred for 4h; the pH value of the solution was adjusted to 9 with ammonia water, and the temperature was lowered to room temperature, filtered, and the filter cake was washed with deionized water until neutral; Prepare a slurry under water, add 30ml of formic acid dropwise, stir for 4 hours, filter, wash the filter cake with deionized water until neutral, and dry it in vacuum at 80°C to obtain a sulfur-doped activated carbon-supported palladium catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com