Preparation method of strong-coupling type attapulgite-KHX-g-C3N4 composite material

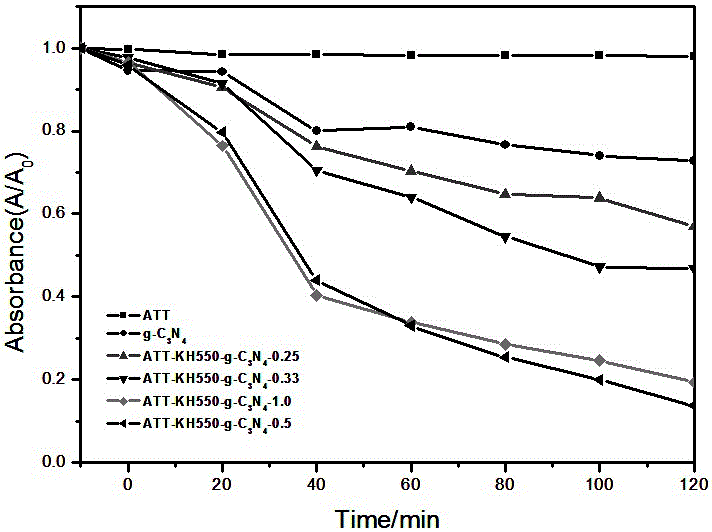

A technology of attapulgite and composite materials, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem that the catalytic activity cannot meet the large-scale application, and achieves good loading effect and firm loading. , the effect of low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

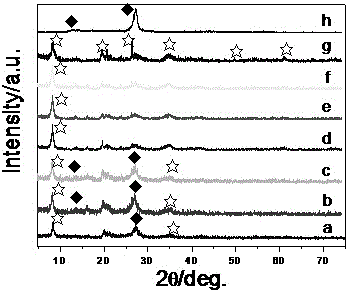

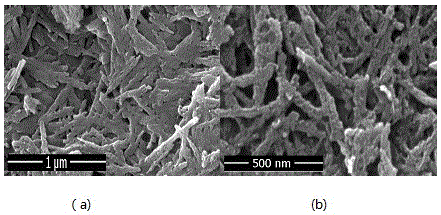

[0015] Embodiment 1: ATT-KH550-g-C is synthesized according to the following steps 3 N 4 -0.5 composite material:

[0016] (a) Weigh 3g of attapulgite and 100mL of toluene into the four-necked flask in turn, stir evenly, heat up to 60°C, after 0.5h, add 2.5mL KH550 while stirring, stir for 4 hours, and the reaction product is separated by filtration After that, it was washed with toluene and absolute ethanol in sequence, and dried at 60°C to obtain ATT-KH550, which was ground and passed through a 200-mesh (74 μm) sieve for later use;

[0017] (b) Weigh 0.302g ATT-KH550 and disperse it in 100mL deionized water, ultrasonically disperse; then add 0.601g melamine, stir, condense and reflux at 80°C for 2h; then freeze-dry for 48h, grind and add to the quartz boat, and the quartz The boat was placed in a tube furnace, and the temperature was programmed in the tube furnace under an air atmosphere. The temperature rise program was as follows: room temperature was raised to 500 °C fo...

Embodiment 2

[0029] Embodiment 2: ATT-KH560-g-C is synthesized according to the following steps 3 N 4 -0.25 Composite:

[0030] (a) Weigh 3g of attapulgite and 100mL of toluene into the four-necked flask in turn, stir evenly, heat up to 60°C, after 0.5h, add 2.5mL of KH560 while stirring, stir for 4 hours, and the reaction product is separated by filtration After that, it was washed with toluene and absolute ethanol in sequence, and dried at 60°C to obtain ATT-KH560, which was ground and passed through a 200-mesh (74 μm) sieve for later use;

[0031] (b) Weigh 0.302g ATT-KH560 and disperse it in 100mL deionized water, ultrasonically disperse; then add 1.208g melamine, stir, condense and reflux at 80°C for 2h; then freeze-dry for 48h, grind and add to the quartz boat, and the quartz boat Placed in a tube furnace, the temperature was programmed to rise in the tube furnace under the air atmosphere. The temperature rise program was as follows: at room temperature, the temperature was raised ...

Embodiment 3

[0032] Embodiment 3: ATT-KH570-g-C is synthesized according to the following steps 3 N 4 -0.5 composite material:

[0033] (a) Weigh 3g of attapulgite and 100mL of toluene into the four-necked flask in turn, stir evenly, raise the temperature to 60°C, after 0.5h, add 2.5mL KH570 while stirring, stir for 4 h, and the reaction product is separated by filtration After that, it was washed with toluene and absolute ethanol in sequence, and dried at 60°C to obtain ATT-KH570, which was ground and passed through a 200-mesh (74 μm) sieve for later use;

[0034] (b) Weigh 0.302g ATT-KH570 and disperse it in 100mL of deionized water, ultrasonically disperse; then add 0.601g melamine, stir, condense and reflux at 80°C for 2h; then freeze-dry for 48h, grind and add to the quartz boat, and the quartz The boat was placed in a tube furnace, and the temperature was programmed to rise in the tube furnace under an air atmosphere. The temperature rise program was as follows: at room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com