Soil thermal desorption repair process and apparatus

A soil thermal and thermal desorption technology, applied in the field of soil remediation, can solve the problems of high pollutant removal rate complete sets of equipment and processes, and achieve the effect of high removal rate and wide range of pollutants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention will be described in more detail below in conjunction with the drawings and implementation cases.

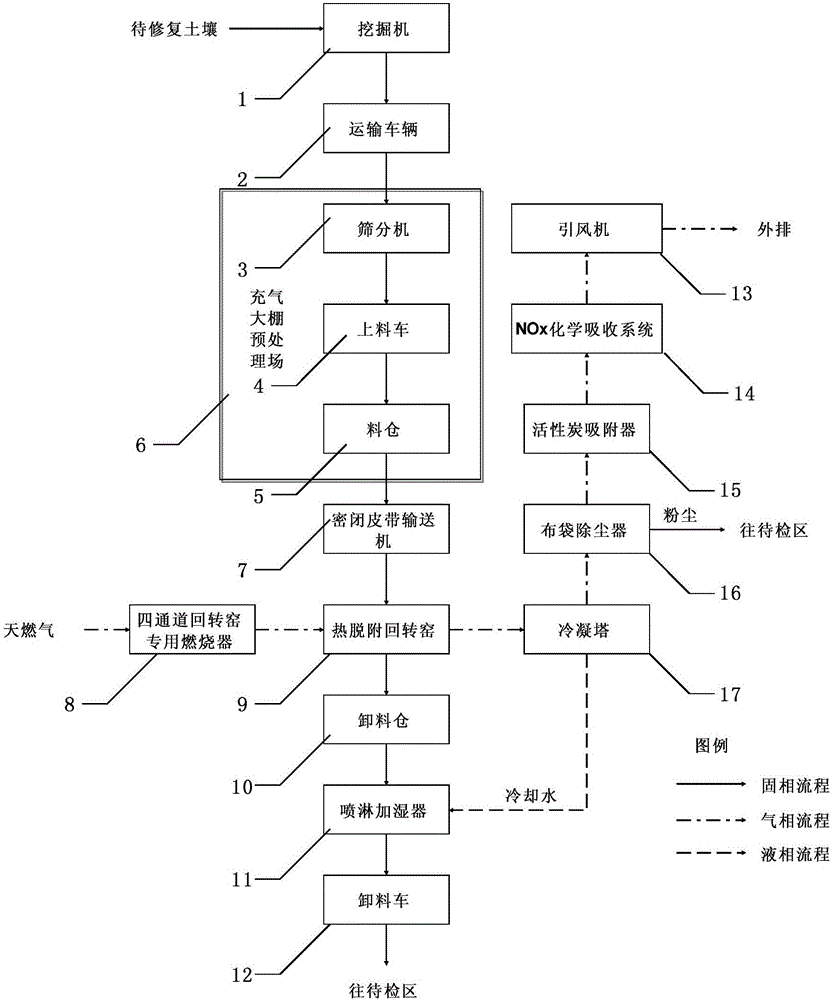

[0018] The equipment used in the soil thermal desorption repair process of the present invention includes a soil pretreatment system, a rotary kiln thermal desorption system, and a rotary kiln tail gas treatment system. For specific structures, see figure 1 As shown, it includes excavator 1, transport vehicle 2, screening machine 3, feeding vehicle 4, silo 5, air-filled greenhouse pretreatment field 6, airtight belt conveyor 7, four-channel rotary kiln dedicated burner 8, heat removal With rotary kiln 9, unloading bin 10, spray humidifier 11, unloading car 12, induced draft fan 13, NO x Chemical absorption system 14, activated carbon adsorber 15, bag filter 16, condensation tower 17. The soil pretreatment system includes an inflatable greenhouse pretreatment field 6. The inflatable greenhouse pretreatment field 6 is equipped with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com