Technique for safe reducing treatment of electroplating sludge

A technology of electroplating sludge and process methods, applied in water/sludge/sewage treatment, pyrolysis treatment of sludge, chemical instruments and methods, etc., can solve the problems of low pollution control level, low equipment level, environmental damage, etc. Achieve the effect of solving environmental pollution problems, wide application range and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

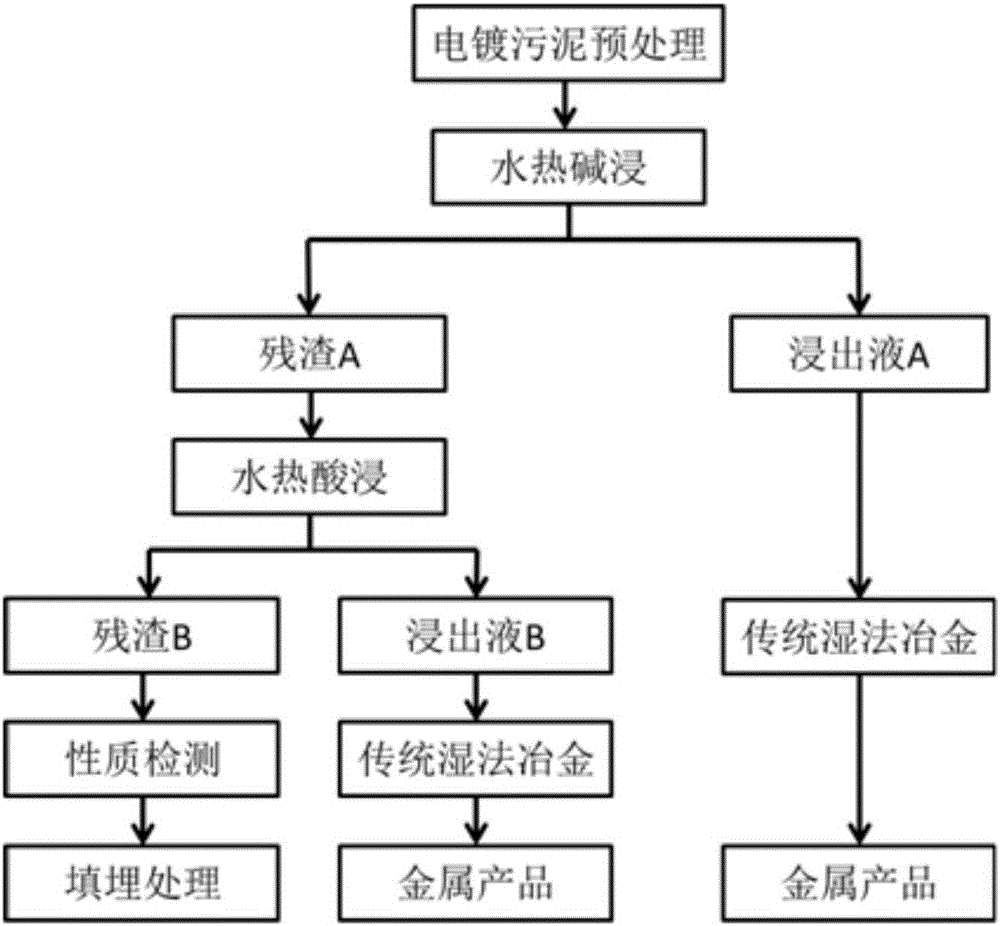

[0038] A process method for safe and reduced-volume disposal of electroplating sludge, comprising the following steps:

[0039] (1) Electroplating sludge pretreatment: take electroplating sludge (water content 65%), use a powerful mixer to crush it and stir it until it is sticky, and it can pass through a 200-mesh sieve;

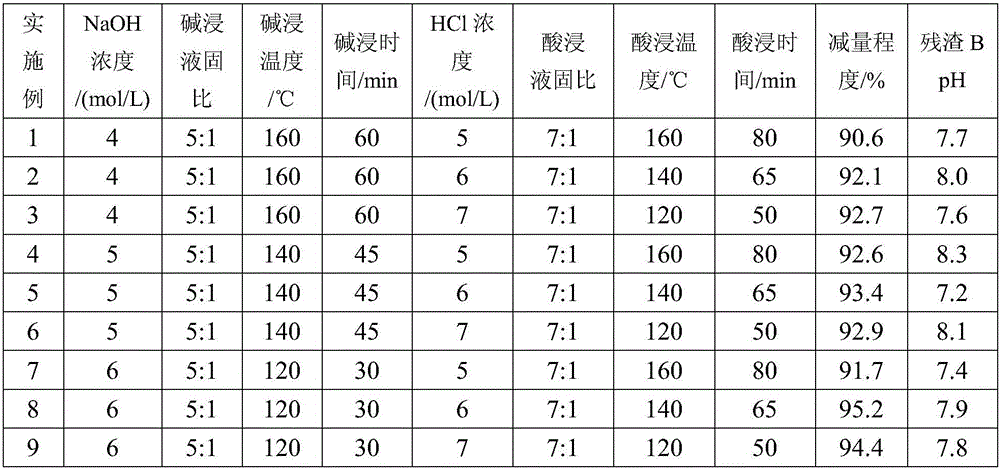

[0040] (2) Take the viscous electroplating sludge obtained in step (1), add NaOH solution with a concentration of 4 to 6mol / L, the liquid-solid ratio of NaOH solution and electroplating sludge is 5:1, and then place it in a high-pressure reactor React at 100-170°C for 30-60 minutes. After the reaction is complete, carry out suction filtration to obtain leachate A and residue A respectively;

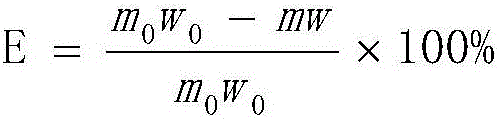

[0041] (3) Take the remaining residue A of step (2), add HCl solution with a concentration of 5-7mol / L, the liquid-solid ratio of HCl solution and residue A is 7:1, and then place it in an autoclave at 120-160 The reaction was carried out at ℃ for 50-80 minutes. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com