Deep dewatering treatment method for co-treatment of beer sludge and beer waste liquids

A technology for beer waste liquid and beer sludge, which is applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc. Large and other problems, to achieve the effect of convenient treatment, cost saving and low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

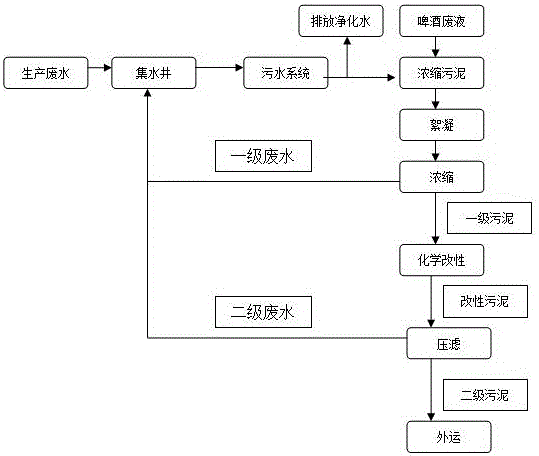

[0035] A method for advanced dehydration treatment of beer sludge in conjunction with beer waste liquid, comprising the following steps:

[0036] Step (A): The production wastewater of the brewery is collected by the water collection well and treated by the sewage treatment system to obtain purified water and beer sludge;

[0037] Step (B): mixing beer sludge and beer waste liquid in the concentration tank to form concentrated sludge;

[0038] Step (C): The concentrated sludge is flocculated and concentrated to separate primary sludge and primary wastewater;

[0039] Step (D): chemically modifying the primary sludge to obtain modified sludge;

[0040] Step (E): Filtering and dehydrating the modified sludge in a screw stacker to obtain secondary sludge and secondary wastewater;

[0041] Step (F): Return the primary wastewater and secondary wastewater to the collection well, mix with the production wastewater and continue to enter the sewage treatment system for treatment unti...

Embodiment 2

[0045] A method for advanced dehydration treatment of beer sludge in conjunction with beer waste liquid, comprising the following steps:

[0046] Step (A): The production wastewater of the brewery is collected by the water collection well and treated by the sewage treatment system to obtain purified water and beer sludge;

[0047] Step (B): mixing beer sludge and beer waste liquid in the concentration tank to form concentrated sludge;

[0048] Step (C): The concentrated sludge is flocculated and concentrated to separate primary sludge and primary wastewater;

[0049] Step (D): chemically modifying the primary sludge to obtain modified sludge;

[0050] Step (E): Filtering and dehydrating the modified sludge in a screw stacker to obtain secondary sludge and secondary wastewater;

[0051] Step (F): Return the primary wastewater and secondary wastewater to the collection well, mix with the production wastewater and continue to enter the sewage treatment system for treatment unti...

Embodiment 3

[0055] A method for advanced dehydration treatment of beer sludge in conjunction with beer waste liquid, comprising the following steps:

[0056] Step (A): The production wastewater of the brewery is collected by the water collection well and treated by the sewage treatment system to obtain purified water and beer sludge;

[0057] Step (B): mixing beer sludge and beer waste liquid in the concentration tank to form concentrated sludge;

[0058] Step (C): The concentrated sludge is flocculated and concentrated to separate primary sludge and primary wastewater;

[0059] Step (D): chemically modifying the primary sludge to obtain modified sludge;

[0060] Step (E): Filtering and dehydrating the modified sludge in a screw stacker to obtain secondary sludge and secondary wastewater;

[0061] Step (F): Return the primary wastewater and secondary wastewater to the collection well, mix with the production wastewater and continue to enter the sewage treatment system for treatment unti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com