High-tetragonal barium titanate doped with rare earth neodymium and preparation method thereof

A phase barium titanate and neodymium doping technology is applied in the field of high tetragonal phase barium titanate and its preparation, which can solve the problems of limiting the application of barium titanate and difficult to meet the requirements of high-performance components and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

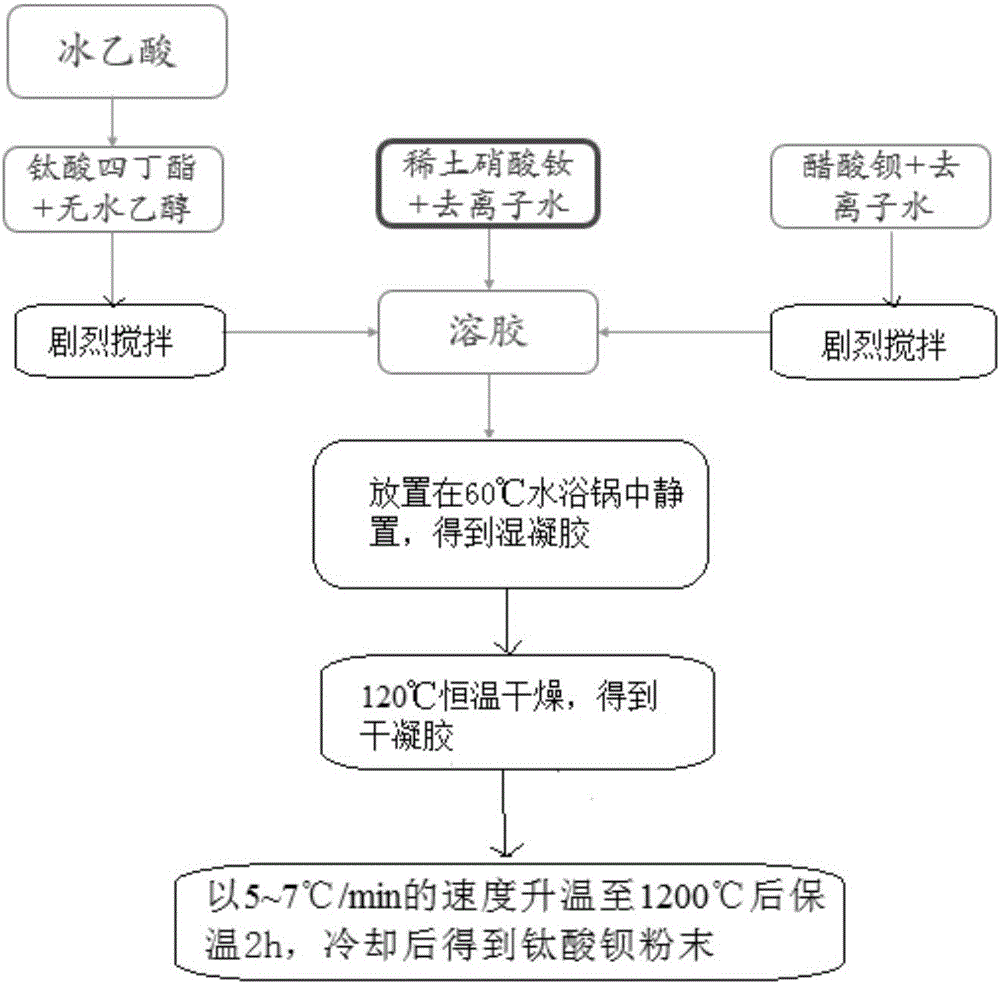

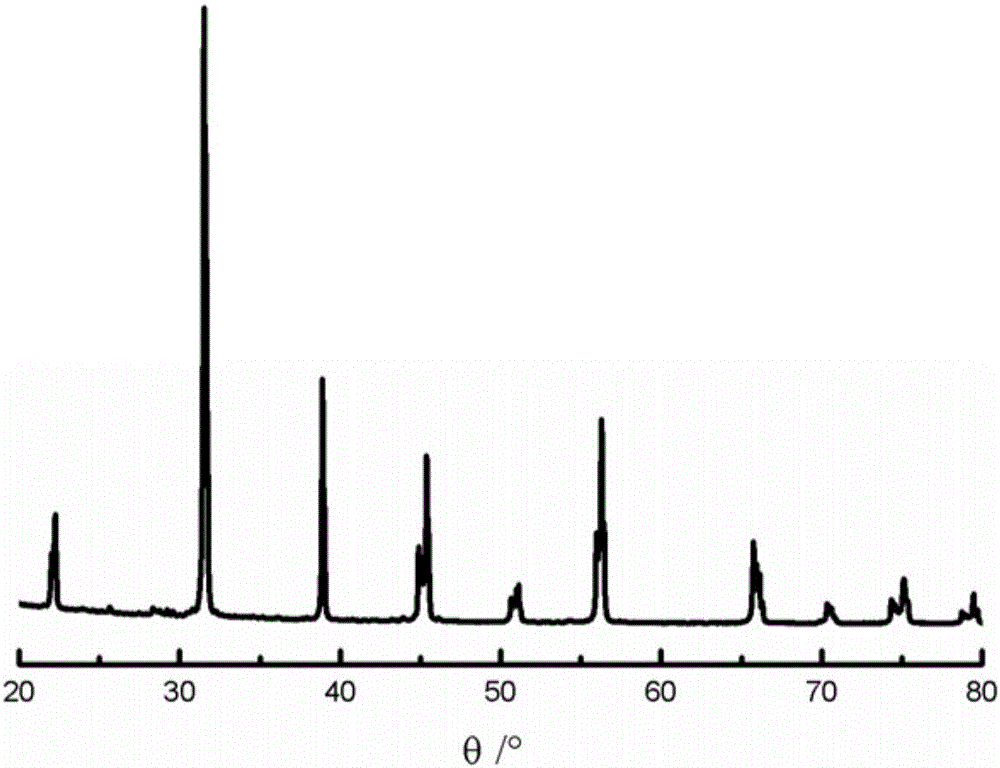

[0028] Aiming at the problems of particle agglomeration, low tetragonal phase content and low electromagnetic performance of barium titanate products in barium titanate prepared at present, the present invention proposes a rare earth neodymium-doped high tetragonal phase barium titanate and its Preparation. Such as figure 1 As shown, it specifically includes:

[0029] Step 1: Dissolve barium acetate in deionized water under a constant temperature water bath at 40-60°C, and stir until completely dissolved to obtain a barium acetate solution with a molar concentration of 1-2.6mol / L; respectively mix neodymium nitrate and titanate Dissolve butyl ester in deionized water and stir until completely dissolved to obtain a rare earth solution with a molar concentration of 0.005-0.015mol / L and a titanium alcohol solution with a molar concentration of 0.9-2.86mol / L;

[0030] Step 2: At room temperature, stir the titanium alcohol solution for 10-20 minutes, then add triethanolamine to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com