Carbon nanotube-enhanced carboxymethyl xylan/polyacrylic acid composite hydrogel and preparation method thereof

A technology of composite hydrogel and carboxymethyl wood is applied in the field of carbon nanotube reinforced carboxymethyl xylan/polyacrylic acid composite hydrogel and its preparation, and can solve the problem of low strength, low strength of biomass-based hydrogel, Restricted applications, carbon nanotubes cannot react, etc., to achieve the effect of easy industrialization, excellent mechanical properties, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

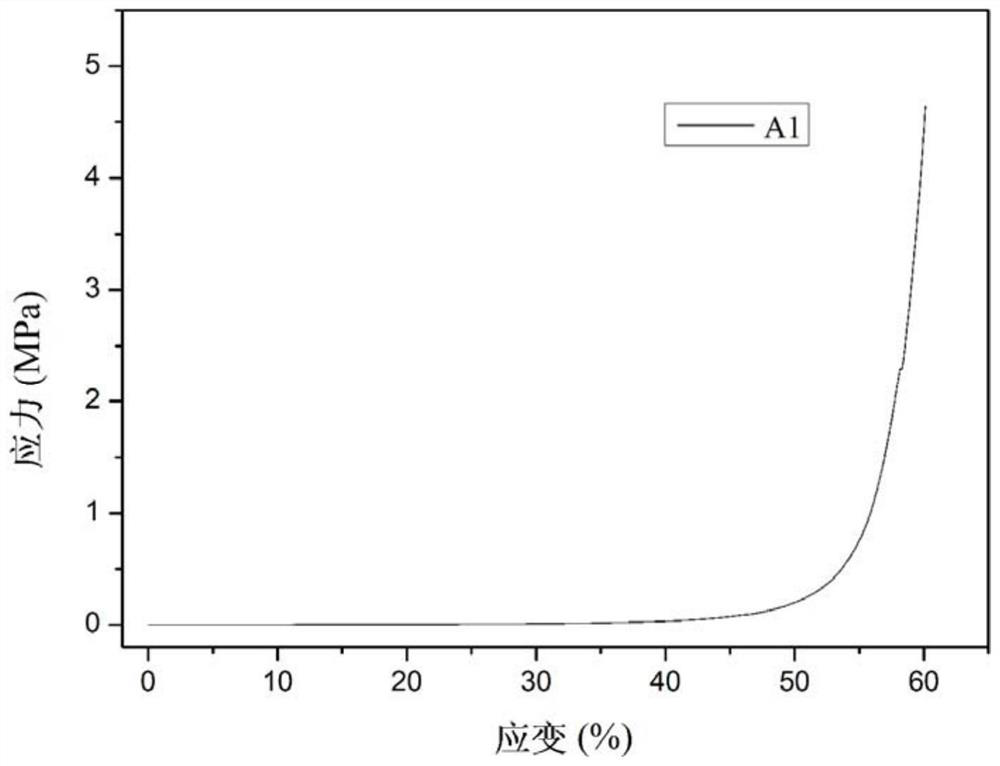

Embodiment 1

[0032] In this example, a carbon nanotube reinforced carboxymethyl group / polyacrylic acid composite hydrogel, the specific preparation steps are as follows:

[0033] (1) Add a sodium hydroxide solution (sodium hydroxide and xylose unit in xylan in xylosaccharide), 0.8: 1), alkalized 10min, sodium chloroacetate (chloroacetic acid) The molar ratio of the xylose unit in sodium and xylose is 1: 1), placed in a microwave reactor, 300W heating to 70 ° C, reaction 10min, fell to room temperature after completion, and 2x volumes of 80 % Ethanol precipitation, filtration, then remove unreacted reagents with ethanol, the obtained precipitate is dissolved, lyophilized, to obtain carboxymethylbacteria;

[0034] (2) Among the acrylic solutions of the mass fraction of 10%, 8 wt% (acrylic) carboxymethylbacterosans, 0.5 wt% (acrylic) carbon nanotubes, 0.5 wt% (based on acrylic acid) FECL 3 , 0.5 wt% (based on acrylic acid) crosslinking agent N, N'-methylene bispacrylamide, nitrogen gas bubbles ...

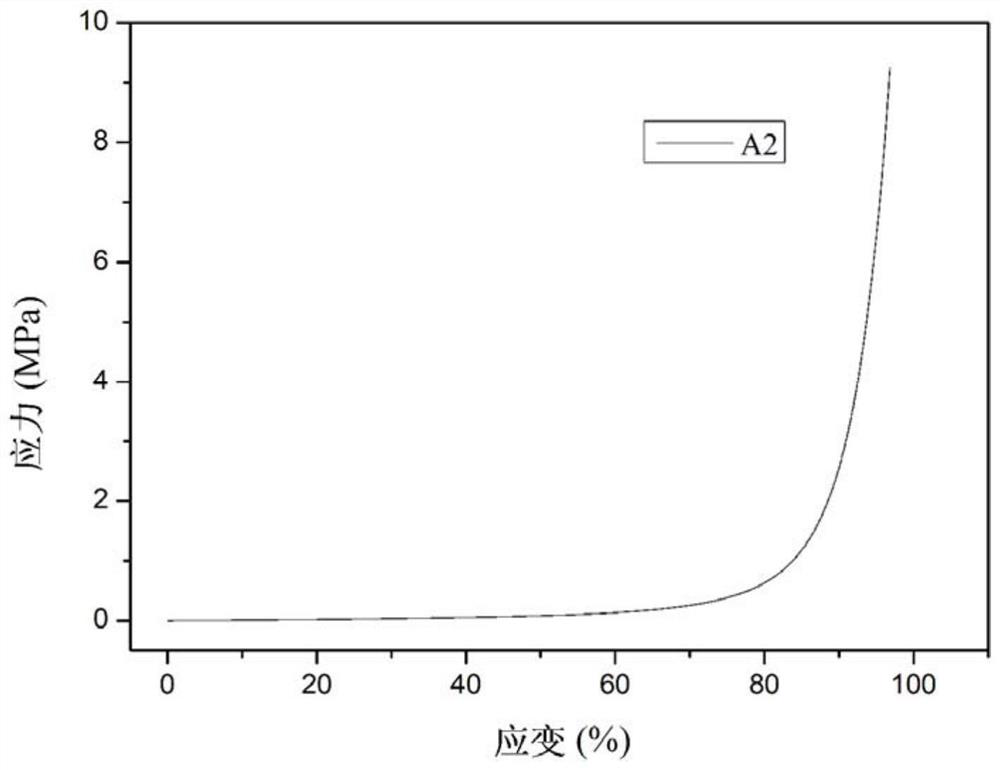

Embodiment 2

[0037] In this example, a carbon nanotube reinforced carboxymethyl group / polyacrylic acid composite hydrogel, the specific preparation steps are as follows:

[0038] (1) Add a sodium hydroxide solution (sodium hydroxide and xylose unit in xylose unit in xylose), 1: 1 of sodium hydroxose unit), alkalized 20min, sodium chloroacetate (chloroacetic acid) The molar ratio of the xylose unit in sodium and xylosaccharide is 2: 1), placed in a microwave reactor, 400W heating to 80 ° C, reaction for 20 min, and fell to room temperature after completion, 3 times volume of 80 of the reaction liquid % Ethanol precipitation, filtration, then remove unreacted reagents with ethanol, the obtained precipitate is dissolved, lyophilized, to obtain carboxymethylbacteria;

[0039] (2) In an acrylic solution of 15%, 10% by weight (acrylic) carboxymethylbin, 2 wt% (based on acrylic) carbon nanotubes, 2 wt% (based on acrylic acid) FECL. 3 , 0.75 wt% (acrylic) crosslinking agent N, N'-methylene bis acryl...

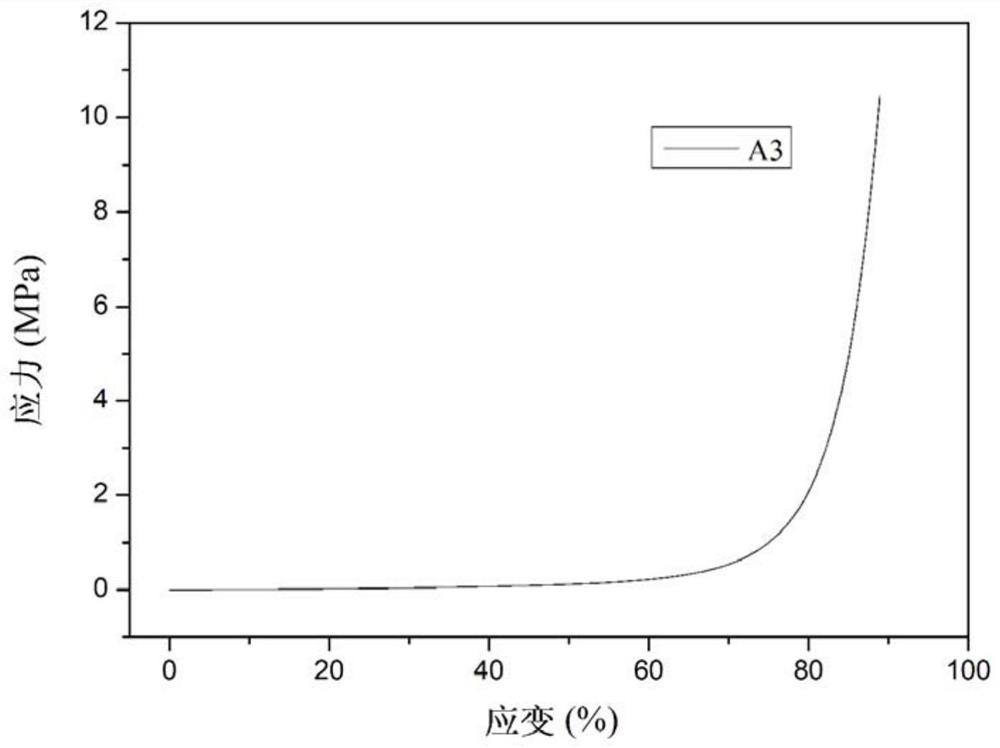

Embodiment 3

[0042] In this example, a carbon nanotube reinforced carboxymethyl group / polyacrylic acid composite hydrogel, the specific preparation steps are as follows:

[0043](1) Add a sodium hydroxide solution (sodium hydroxide with xylose unit in xylan) to 4 wt% of xylosan solution (sodium hydrolyzate), alkalized 30min, sodium chloroacetate (chloroacetic acid) The molar ratio of the xylose unit in sodium and xylosaccharide is 3: 1), placed in a microwave reactor, 550W heating to 90 ° C, reactive 30 min, and fell to room temperature after the reaction is completed, 80 of the reaction liquid % Ethanol precipitation, filtration, then remove unreacted reagents with ethanol, the obtained precipitate is dissolved, lyophilized, to obtain carboxymethylbacteria;

[0044] (2) Among the acrylic solutions of mass fraction of 20%, 12 wt% (acrylic) based carboxymethylbin, 4 wt% (acrylic acid) carbon nanotubes, 2.5 wt% (based on acrylic acid) FECL 3 1 wt% (acrylic acid) crosslinking agent N, N'-methyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com