Preparation method for rare earth niobate high-temperature ceramics

A technology of high-temperature ceramics and niobate, applied in the field of high-temperature materials, can solve the problems of coating failure, poor phase stability and high thermal conductivity, and achieve the effects of good high-temperature thermal stability, low impurity content and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

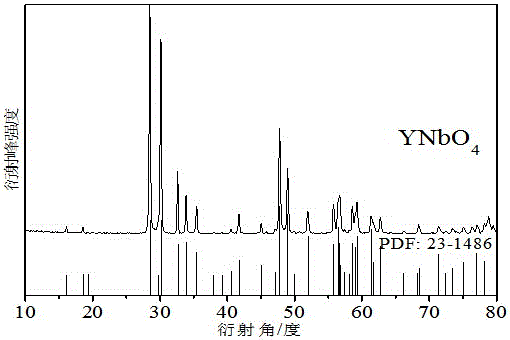

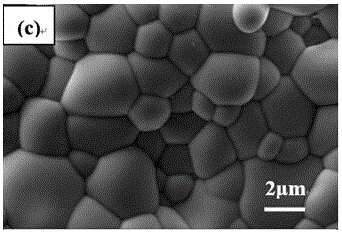

[0029] A new type of high temperature resistance, anti-oxidation, anti-wear yttrium niobate (YNbO 4 ) ceramic material and preparation method thereof, specifically comprising the following steps:

[0030] Weigh 12.7984g of yttrium oxide and 15.0654g of niobium oxide, mix them in absolute ethanol, put them into a planetary ball mill (the speed of the ball mill is 300 r / min, and the ball milling time is 180 min), mix 0.2 mL of polyvinyl alcohol The hydrogel was added to the mixture A that had just been ball-milled and ball-milled again for 60 min, and the mass percent concentration of polyvinyl alcohol hydrogel was 5%; then the ball-milled solution was dried at 60°C for 24 hours and passed through a 300-mesh sieve , and then pressed into a mold (holding pressure 8 MPa, holding time 60 min), after pressing, it was pre-fired at 800 °C for 10 hours.

[0031] After calcining the raw materials for the first time, grind the mixture evenly, dissolve it again in absolute ethanol, and p...

Embodiment 2

[0034] A new type of high temperature resistance, anti-oxidation, anti-wear neodymium niobate (NdNbO 4 ) ceramic material and preparation method thereof, specifically comprising the following steps:

[0035] Weigh 19.0715g of neodymium oxide and 15.0654g of niobium oxide, mix them in absolute ethanol, put them into a planetary ball mill (the speed of the ball mill is 320 r / min, and the ball milling time is 170 min), mix 0.2mL of polyvinyl alcohol The hydrogel was added to the mixture A that had just been ball milled and ball milled again for 50 min. The mass percent concentration of polyvinyl alcohol hydrogel was 6%; then the ball milled solution was dried at 64 °C for 22 hours and passed through a 300 mesh sieve , and then pressed into a mold (holding pressure 9 MPa, holding time 55 min), after pressing, it was pre-fired at 850 °C for 9 hours.

[0036]After the raw materials were calcined for the first time, the mixture was ground evenly, dissolved in absolute ethanol again,...

Embodiment 3

[0038] A new type of high temperature resistance, anti-oxidation, anti-wear samarium niobate (SmNbO) described in this embodiment 4 ) ceramic material and preparation method thereof, specifically comprising the following steps:

[0039] Weigh 19.7646g of samarium oxide and 15.0654g of niobium oxide, mix them in absolute ethanol, put them into a planetary ball mill (the speed of the ball mill is 340 r / min, and the ball milling time is 160 min), mix 0.2mL polyvinyl alcohol The hydrogel was added to the mixture A that had just been ball-milled and ball-milled again for 45 min, and the mass percent concentration of polyvinyl alcohol hydrogel was 7%; then the ball-milled solution was dried at 66°C for 20 hours and passed through a 300-mesh sieve , and then pressed into a mold (holding pressure 10 MPa, holding time 50 min), after pressing, it was pre-fired at 900 °C for 8 hours.

[0040] After calcining the raw materials for the first time, grind the mixture evenly, dissolve it aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com