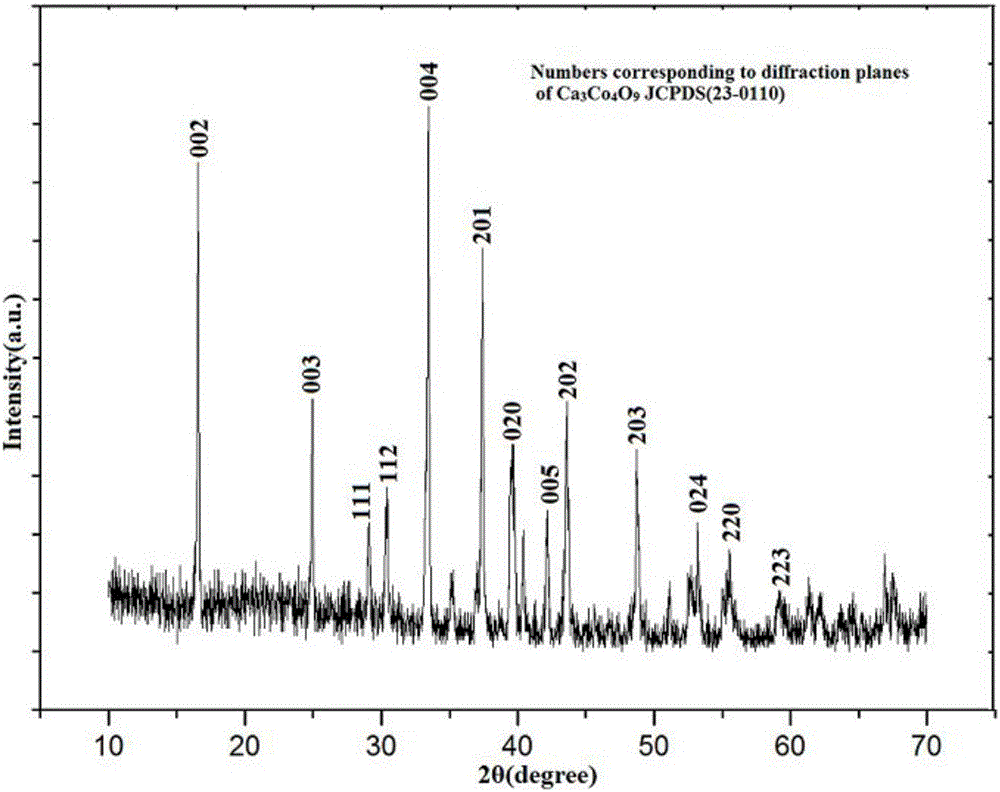

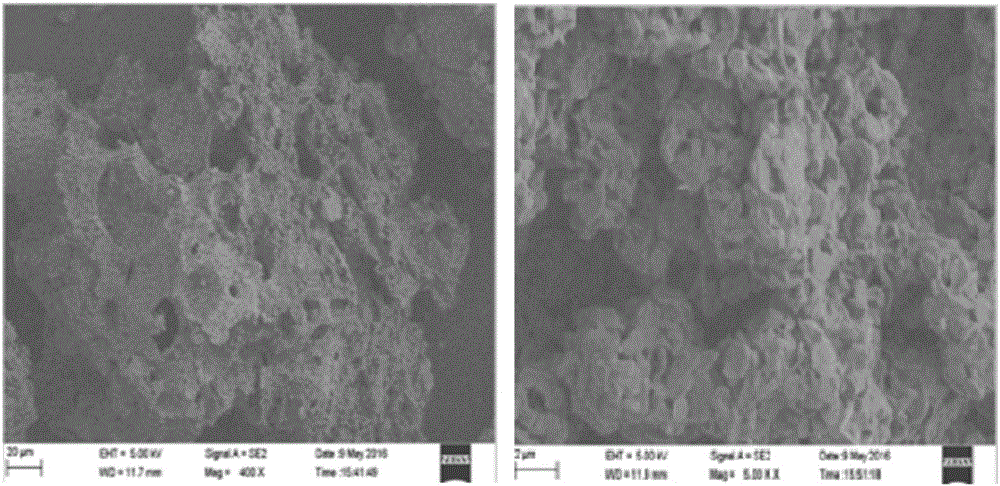

Preparation method of Ca3Co4O9 thermoelectric material

A thermoelectric material and gel method technology, which is applied in ceramic products, applications, household appliances, etc., can solve the problems of thermoelectric materials with few holes, high raw material cost, and inability to achieve, and achieves low cost, improved thermoelectric performance, and improved performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] Preparation of Ca 3 co 4 o 9 Thermoelectric material: use inorganic acetate as raw material and citric acid as complexing agent to form sol and gel, then pre-calcine to obtain precursor nano-powder, and then sinter it. The process is carried out as follows:

[0013] (1) Add calcium carbonate and cobalt acetate to the reaction vessel according to the stoichiometric ratio, add citric acid, the ratio is calcium carbonate: cobalt acetate: citric acid = 3mol: 4mol: 7.5mol, then add deionized water to dissolve the mixture, and dissolve the mixture Put it on a magnetic stirrer to heat and stir, and set the stirring speed at 90 rpm. While stirring, gradually increase the temperature from room temperature to 115°C until the solution turns into a purple-red xerogel;

[0014] (2) Grind the xerogel obtained in step (1) and pre-calcine at 350°C to remove the citric acid in it, and sinter the obtained powder at 800°C to obtain Ca 3 co 4 o 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com