A kind of preparation method of high molecular weight phenoxy resin

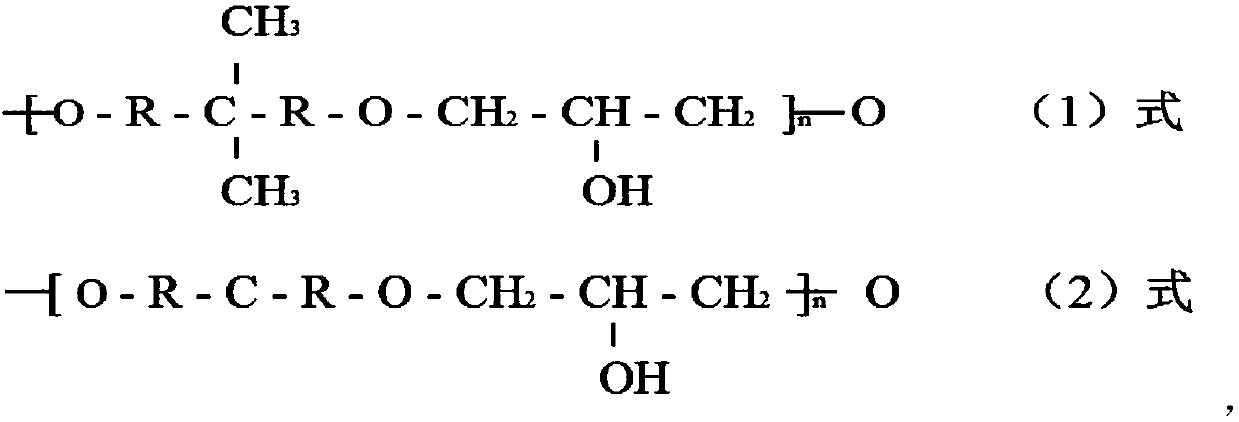

A phenoxy resin and high-molecular-weight technology, which is applied in the field of preparation of high-molecular-weight phenoxy resin, can solve problems such as high water content in products, affecting product performance, and difficulty in dehydration, so as to achieve easy control of reactions, less raw material residues, and product color. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the high molecular weight phenoxy resin of the present embodiment is carried out according to the following steps:

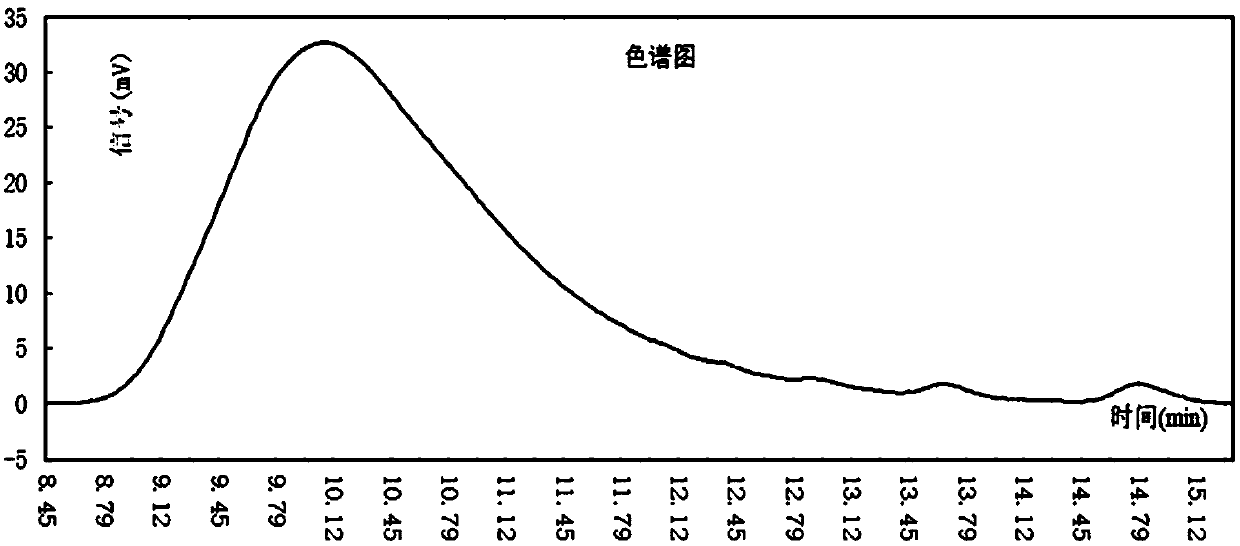

[0032] (1) In a 2000Ml glass-made 4-port detachable flask experimental device equipped with a stirring device, a thermometer, a condenser, and a nitrogen inlet pipe, 55 parts of liquid bisphenol A type 128 epoxy resin, 195 parts of bisphenol A type 604 Solid epoxy resin and 65 parts of bisphenol A are used as raw materials. Under the condition of nitrogen protection, the raw materials are dissolved in 160ml of MIBK solvent at 80°C, and 4 parts of 40% KOH solution of basic catalyst are added, and the reaction is carried out at 90°C for 5 hours. During the reaction, the solvent was added every 30 minutes. The total amount of added solvent was 3 times the weight of the solvent when feeding. Gel permeation chromatography was used to detect the molecular weight of the reaction product in real time. After the molecular weight reached 70...

Embodiment 2

[0035] The preparation method of the high molecular weight phenoxy resin of the present embodiment is carried out according to the following steps:

[0036] (1) In a 2000Ml glass-made 4-port detachable flask experimental device equipped with a stirring device, a thermometer, a condenser, and a nitrogen inlet pipe, 55 parts of liquid bisphenol A type 128 epoxy resin, 195 parts of bisphenol A type 604 Solid epoxy resin and 65 parts of bisphenol A are used as raw materials, and the raw materials are dissolved in 160ml of toluene and butanol mixed solvent at 85°C under the condition of nitrogen protection, and 4 parts of 40% KOH solution of basic catalyst are added. React for 6 hours. During the reaction, add a solvent every 30 minutes. The total amount of added solvent is 4 times the weight of the solvent when feeding. Use gel permeation chromatography to detect the molecular weight of the reaction product in real time. After the molecular weight reaches 70,000 Phosphoric acid wa...

Embodiment 3

[0039] The preparation method of the high molecular weight phenoxy resin of the present embodiment is carried out according to the following steps:

[0040] (1) In a 2000Ml glass-made 4-port detachable flask experimental device equipped with a stirring device, a thermometer, a condenser, and a nitrogen inlet pipe, 55 parts of liquid bisphenol A type 128 epoxy resin, 195 parts of bisphenol A type 604 Solid epoxy resin and 57 parts of bisphenol F are used as raw materials. Dissolve the raw materials in 160ml of MIBK solvent at 90°C under nitrogen protection, add 4 parts of 40% KOH solution of basic catalyst, and react at 90°C for 5 hours. During the reaction, add a solvent every 30min, the added total amount of the added solvent is 3 times of the solvent weight when feeding, adopt gel permeation chromatography to detect the molecular weight of the reaction product in real time, add phosphoric acid after the molecular weight reaches 70000, stop reaction;

[0041] (2) Wash the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com