Organic silicon cationic light-cured resin containing oxetane structure and preparation method of resin

A technology of light-curing resin and oxetane, which is applied in the field of ultraviolet light-curing silicon-containing resin preparation, can solve the problems of poor compatibility between silicone and resin, unsatisfactory comprehensive performance, etc., and achieve the effect of small volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 44.05g of 3-hydroxymethyloxetane, add it dropwise to 87.08g of toluene diisocyanate (TDI), and add 0.06g of dibutyltin dilaurate, maintain the temperature at 40°C for 2h, then raise the temperature Keep warm at 70°C, stop the reaction when the NCO content reaches the theoretical value, and obtain polyurethane semi-adduct A1.

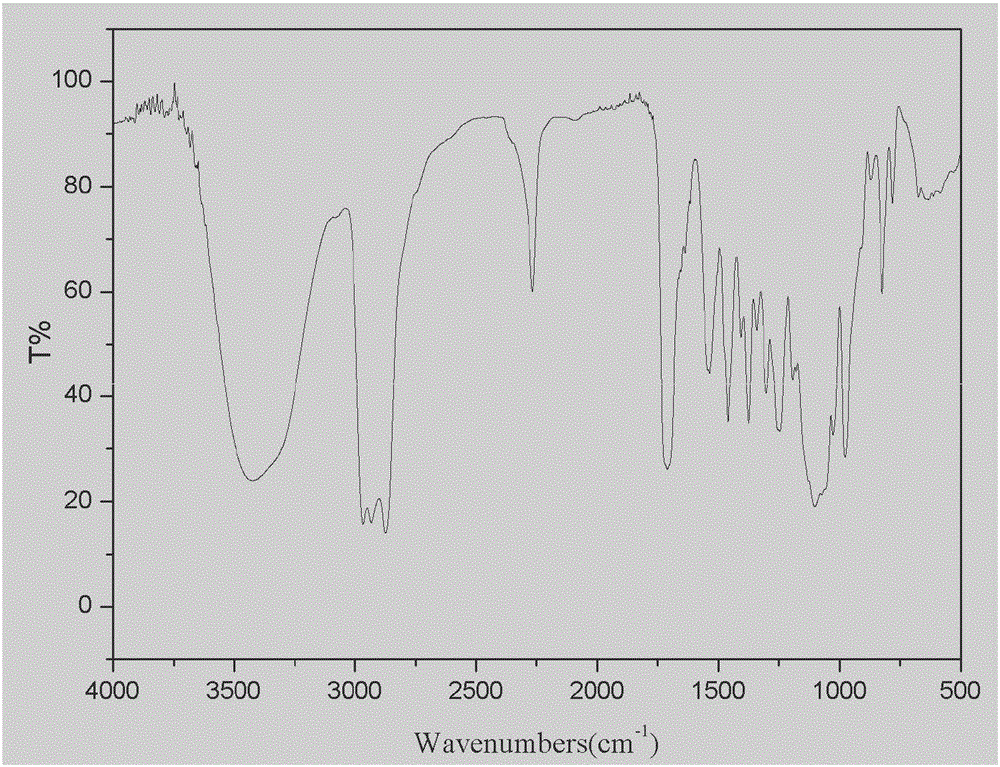

[0033] Weigh 64.05g of dimethylol-terminated polysiloxane (hydroxyl value: 43.72mg KOH / g), add 13.11g of the prepared product A1 to it, and add 0.03g of dibutyltin dilaurate, react at 70°C , until the absorption peak of NCO in the infrared spectrum disappears, stop the reaction, and obtain the organosilicon cationic photocurable resin B1 containing the oxetane structure.

[0034] Prepared resin B1: viscosity is 1520mPa s (GB / T 9269-1988, 60°C); refractive index is 1.51; chromaticity is (APHA) 1G; elongation is 122%; Tg is -22°C; pencil hardness It is 2H; the volume shrinkage rate reaches 3%; the adhesion level is 0.

Embodiment 2

[0036] Weigh 22.03g of 3-hydroxymethyloxetane, add it dropwise to 62.56g of diphenylmethane diisocyanate (MDI), add 0.04g of dibutyltin dilaurate, and keep the temperature at 50°C for 1h Afterwards, the temperature was raised to 80° C. to keep the temperature, and the reaction was stopped when the NCO content reached the theoretical value, and the polyurethane semi-adduct A2 was obtained.

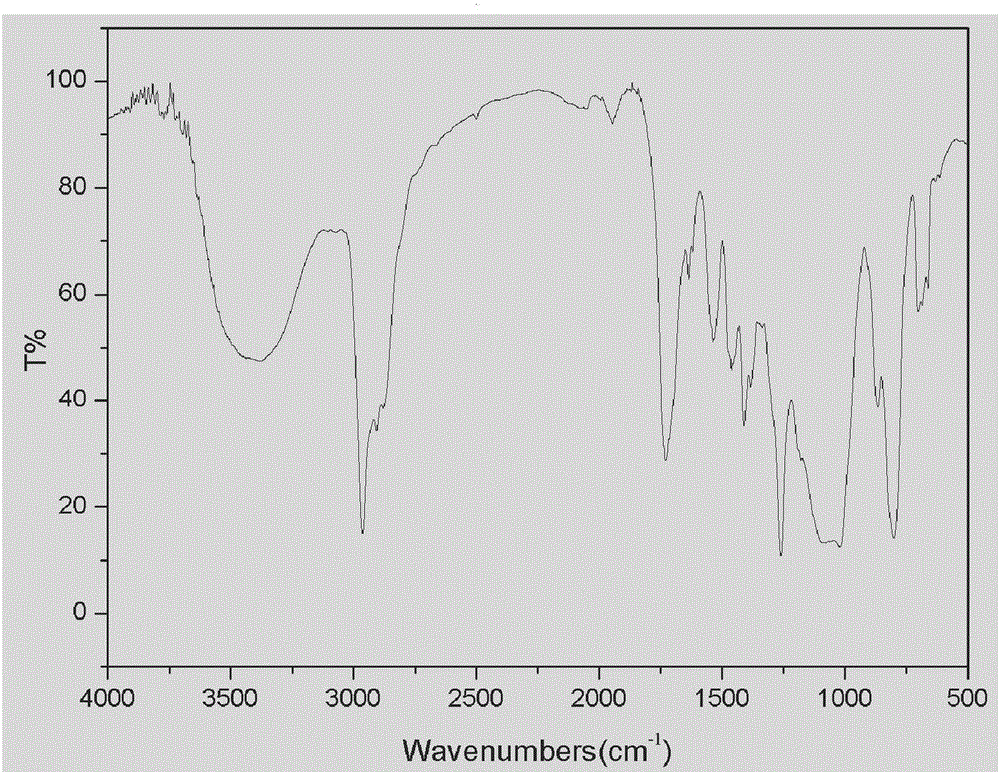

[0037] Weigh 65.45g of dihydroxypropyl-terminated polysiloxane (hydroxyl value 42.78mg KOH / g), add 16.92g of the prepared product A2 to it, and add 0.04g of dibutyltin dilaurate, and react at 80°C , until the absorption peak of NCO in the infrared spectrogram disappears, the reaction is stopped, and the organic silicon cationic photocurable resin B2 containing the oxetane structure is obtained.

[0038] Prepared resin B2: viscosity is 1610mPa s (GB / T 9269-1988, 60°C); refractive index is 1.52; chromaticity is (APHA) 1G; elongation is 108%; Tg is -20°C; pencil hardness It is 3H; the volume ...

Embodiment 3

[0040] Weigh 22.03g of 3-hydroxymethyloxetane, add it dropwise to 55.57g of isophorone diisocyanate (IPDI), and add 0.04g of dibutyltin dilaurate, and maintain the temperature at 45°C for 1.5 After one hour, the temperature was raised to 65°C to keep the temperature, and when the NCO content reached the theoretical value, the reaction was stopped to obtain the polyurethane semi-adduct A3.

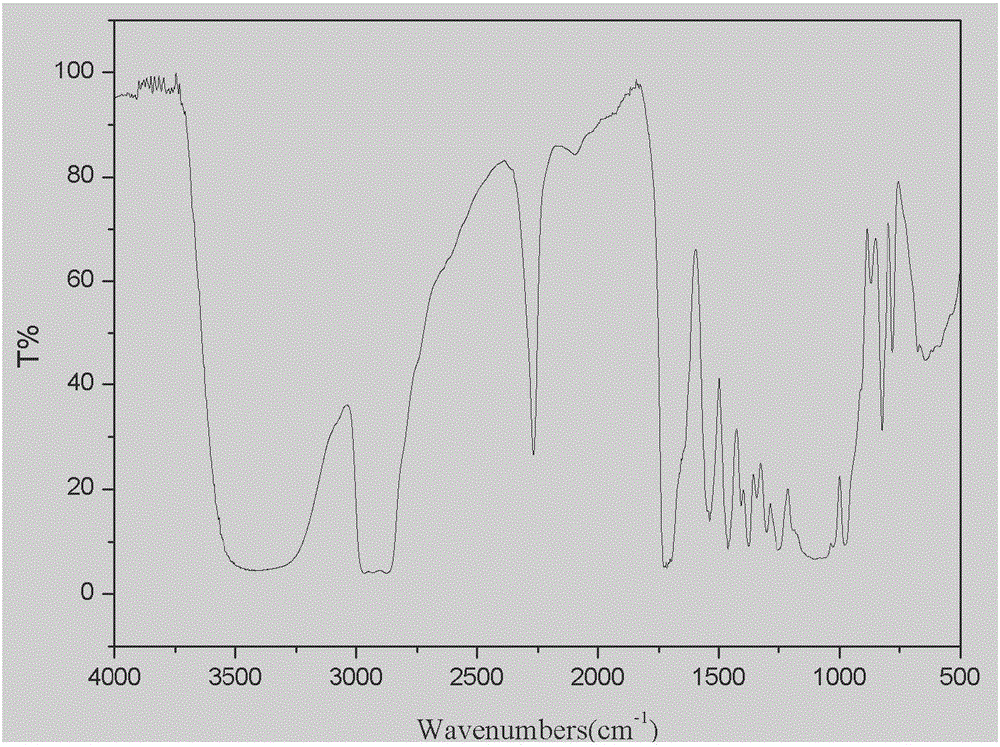

[0041] Weigh 64.05g of dimethylol-terminated polysiloxane (hydroxyl value 43.72mg KOH / g), add 15.52g of the prepared product A3 to it, and add 0.04g of dibutyltin dilaurate, react at 65°C , until the absorption peak of NCO in the infrared spectrum disappears, stop the reaction, and obtain the organosilicon cationic photocurable resin B3 containing the oxetane structure.

[0042] Prepared resin B3: viscosity is 1589mPa s (GB / T 9269-1988, 60°C); refractive index is 1.47; chroma is (APHA) 25; elongation is 150%; Tg is -30°C; pencil hardness It is 1H; the volume shrinkage rate reaches 2%; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com