Transparent high-strength self-leveling methanol-removed single-component organic silica gel and preparation method thereof

A silicone, high-strength technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of non-self-leveling, non-protruding high strength, yellowing of rubber materials, etc. , to achieve the effect of solving storage stability, excellent transparency, and eliminating thixotropic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

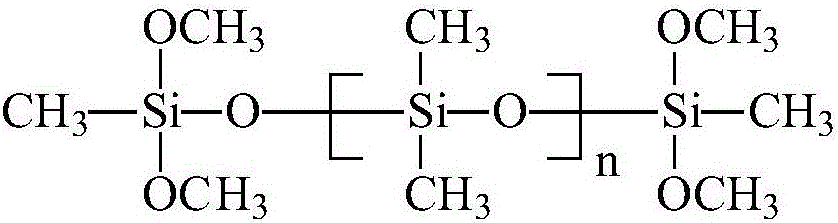

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of a transparent high-strength self-leveling demethanol type one-component organic silica gel comprises the following steps:

[0045] 1) Add alkoxy-terminated polydimethylsiloxane, reinforcing filler, plasticizer, and hydroxyl scavenger into a planetary mixer, and stir and mix under vacuum;

[0046] 2) Add a crosslinking agent in the mixture obtained in the previous step, and disperse and stir under vacuum;

[0047] 3) Add coupling agent and catalyst, disperse and stir under vacuum to prepare transparent high-strength self-leveling demethanolized silica gel.

[0048] Preferably, in step 1), the vacuum degree is 0.075-0.095MPa, the rotation speed is 600-800rpm, and the stirring time is 20-120min; further preferably, in step 1), the vacuum degree is 0.08-0.09 MPa, the rotating speed is 650~750rpm, and the stirring time is 40~60min.

[0049] Preferably, in step 2), the vacuum degree is 0.075-0.095MPa, the rotation speed is 300-500rpm, and the stirrin...

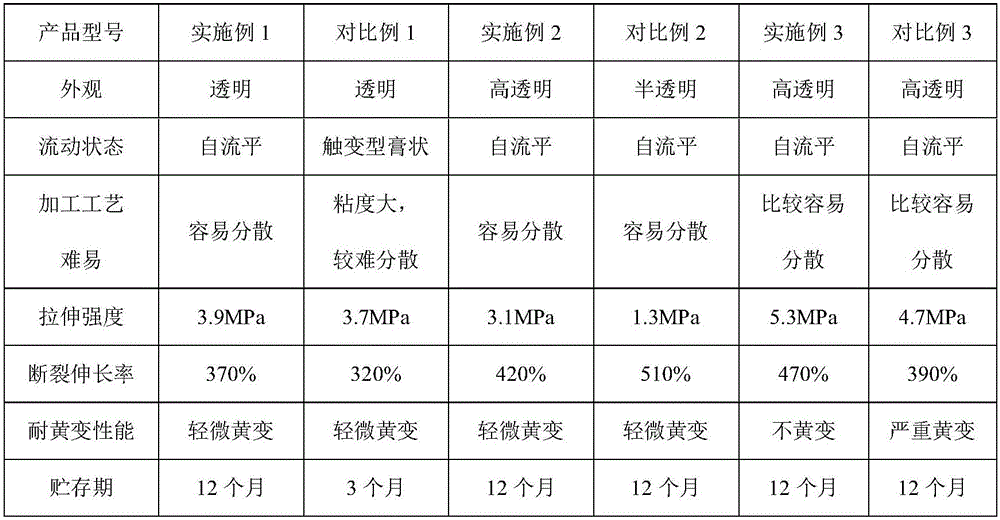

Embodiment 1

[0053] (1) In the planetary stirring tank, add 100 parts by mass of polydimethylsiloxane with a viscosity of 1500mPa·s at 25°C and a polydimethylsiloxane with a viscosity of 100mPa·s. Base silicone oil 10 mass parts, specific surface area 220m 2 20 mass parts of hydrophilic fumed silica / g, 3 mass parts of vinyltriisopropenyloxysilane, stirred and dispersed at 700 rpm for 50 min under a vacuum of 0.085 MPa;

[0054] (2) Add 13 parts by mass of tetramethoxysilane oligomer, stir and disperse at 400 rpm for 30 min under a vacuum of 0.085 MPa;

[0055] (3) Add 1.5 parts by mass of γ-(2,3-epoxy, propoxy)propyltrimethoxysilane, 1.5 parts by mass of γ-aminopropyltrimethoxysilane, and 0.5 parts by mass of stannous octoate, at 0.085MPa Stir and disperse at 400rpm under vacuum for 40min;

Embodiment 2

[0063] (1) In the planetary stirring tank, add 100 parts by mass of polydimethylsiloxane with a viscosity of 5000 mPa·s at 25 °C and a specific surface area of 400 mPa. 2 10 mass parts of hydrophilic fumed silica / g, 7 mass parts of vinyltriisopropenyloxysilane, stirred and dispersed at 700 rpm for 50 min under a vacuum of 0.085 MPa;

[0064] (2) Add 10 parts by mass of tetramethoxysilane oligomer, stir and disperse at 400 rpm for 30 min under a vacuum of 0.085 MPa;

[0065] (3) Add 2.5 parts by mass of γ-(2,3-epoxy, propoxy)propyltrimethoxysilane, 1.5 parts by mass of γ-aminopropyltrimethoxysilane, 3-mercaptopropyltrimethoxysilane Parts by mass, 1.5 parts by mass of dibutyltin dilaurate, stirred and dispersed at 400rpm for 40min under a vacuum of 0.085MPa;

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com