Method for identifying sulfonamide accelerant in rubber

A technology of sulfenamides and an identification method, which is applied in the identification field of sulfenamide accelerators in rubber mixing, can solve the problems that there are no literatures and methods for the identification method of sulfenamides accelerators, and the method is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

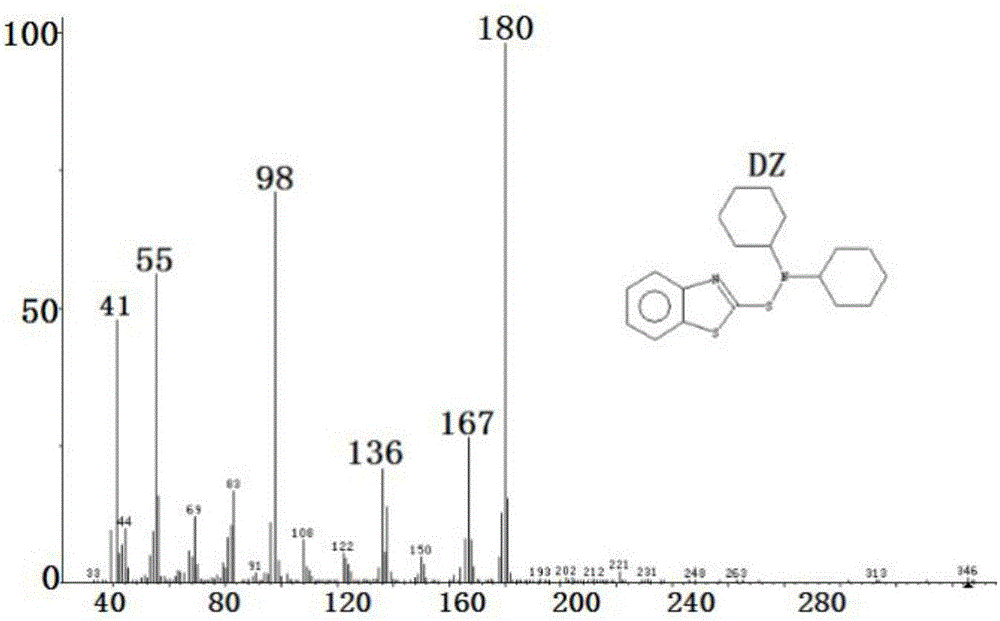

[0042] Example 1: Analysis of sulfenamide accelerators in laboratory prepared mixed rubber

[0043] The basic formula of compounded rubber is (parts by mass): 40 parts of natural rubber NR, 60 parts of butadiene rubber BR; 75 parts of carbon black N37575, 4.0 parts of process oil, 2.0 parts of stearic acid, 1.5 parts of zinc oxide, and 4.0 parts of tackifying resin , 2.0 parts of anti-aging agent 4020, 1.5 parts of anti-aging agent RD, 1.5 parts of sulfur, and 1.6 parts of vulcanization accelerator DZ. The total amount of rubber samples is 193.1 parts.

[0044] Preparation process: use a 1.6-liter Banbury internal mixer (produced by FARREL Company), mix rubber, carbon black and other compounds except sulfur and vulcanization accelerator DZ for 6 minutes and heat up to 160 ° C to obtain a master batch, and Cool the masterbatch to below 90°C; then use an open rubber mixer to mix vulcanization accelerator and sulfur into the masterbatch, and knead the above mixture for 10 minutes ...

Embodiment 2

[0049] Embodiment 2: Qualitative analysis of sulfenamide accelerator in unknown mixed rubber sample

[0050] Sample source: provided by a tire factory.

[0051] The sample was prepared with a liquid nitrogen cryo-grinder to be less than 1.0mm 3 Take 1025.3 mg of colloidal particles, according to the GB / T3516-2006 method, methanol is used as a solvent to prepare a sample extract, and the extract is analyzed by a GC / MS system. The chromatographic conditions are the same as in Example 1.

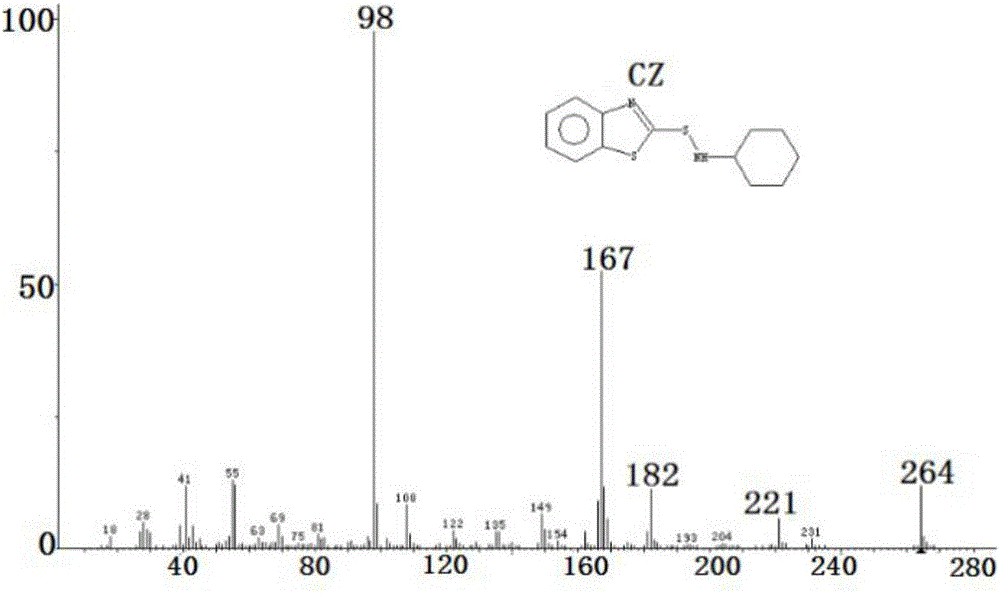

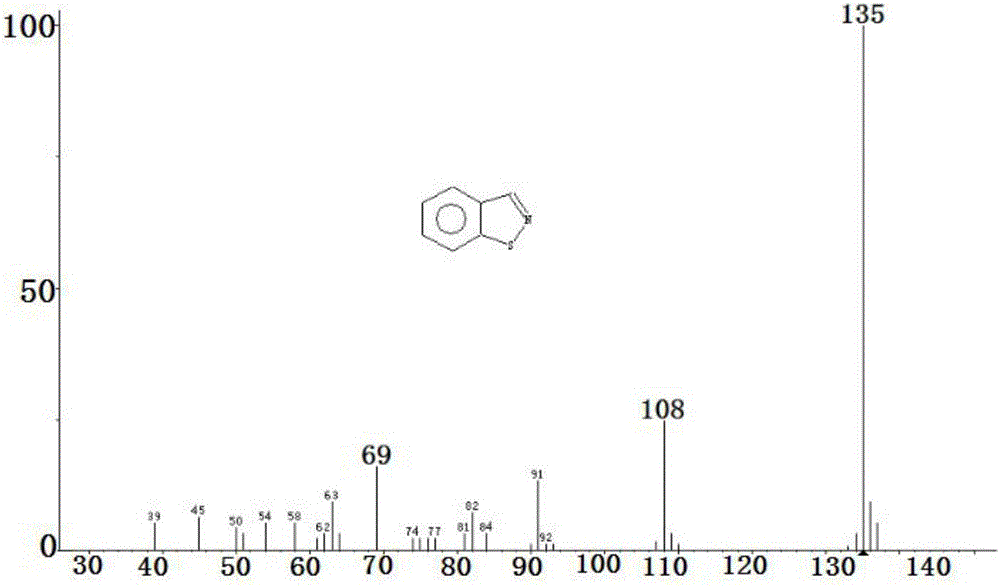

[0052] The total ion chromatogram (see Image 6 C). The chromatogram when finding extraction ion m / z=98, 167 in sample total ion flow chart (see Image 6 D) The mass spectrogram and accelerator CZ mass spectrogram ( figure 2 ) are the same, and the substance peak at the retention time t=22.91min is the accelerator CZ, so it is determined that the accelerator CZ is added in the mixed rubber sample.

[0053] In order to determine whether the sample contains high-boiling sulfenamide accelera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com