High-reliability neutralizing transformer and fabrication method thereof

A manufacturing method and reliable technology, applied in the manufacture of inductors/transformers/magnets, parts of transformers/inductors, coils, etc., can solve the problems of small voltage difference, poor electromagnetic shielding, and short service life of neutralizing transformers , to achieve the effect of low saturation magnetic induction, good stability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

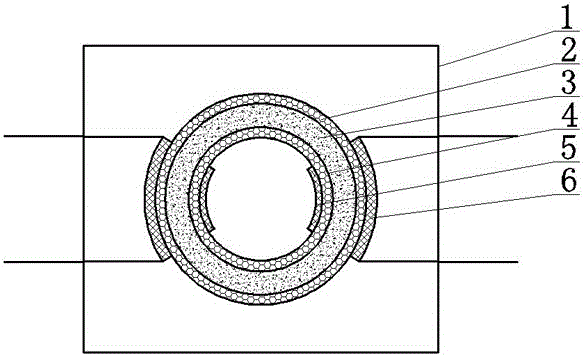

[0044] Such as figure 1A high-reliability neutralization transformer shown in the figure uses a special molybdenum permal core 3, carbon fiber wire with 1140 epoxy polyester insulating paint, a specific ceramic skeleton 2, and an aluminum alloy full Closed shielding cover 1. Heat-vulcanized silicone rubber is applied; the molybdenum Permal magnetic core 3 is sealed in the ceramic skeleton 2 by epoxy resin, and the carbon fiber wire is wound on the ceramic skeleton 2 according to the standard method to form a winding 6. The surface of the winding 6 And the gap between the winding 6 and the ceramic skeleton 2 is filled with heat vulcanized silicone rubber, and the heat vulcanized silicon rubber is also encapsulated with epoxy resin; the aluminum alloy shielding cover 1 covers the entire neutralization transformer except the shielding cover 1 , using a fully enclosed structure.

[0045] The high-reliability neutralization transformer manufacturing method includes the following s...

Embodiment 2

[0079] Such as figure 1 A high-reliability neutralization transformer shown in the figure uses a special molybdenum permal core 3, carbon fiber wire with 1140 epoxy polyester insulating paint, a specific ceramic skeleton 2, and an aluminum alloy full Closed shielding cover 1. Heat-vulcanized silicone rubber is applied; the molybdenum Permal magnetic core 3 is sealed in the ceramic skeleton 2 by epoxy resin, and the carbon fiber wire is wound on the ceramic skeleton 2 according to the standard method to form a winding 6. The surface of the winding 6 And the gap between the winding 6 and the ceramic skeleton 2 is filled with heat vulcanized silicone rubber, and the heat vulcanized silicon rubber is also encapsulated with epoxy resin; the aluminum alloy shielding cover 1 covers the entire neutralization transformer except the shielding cover 1 , using a fully enclosed structure.

[0080] The high-reliability neutralization transformer manufacturing method includes the following ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dielectric strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com