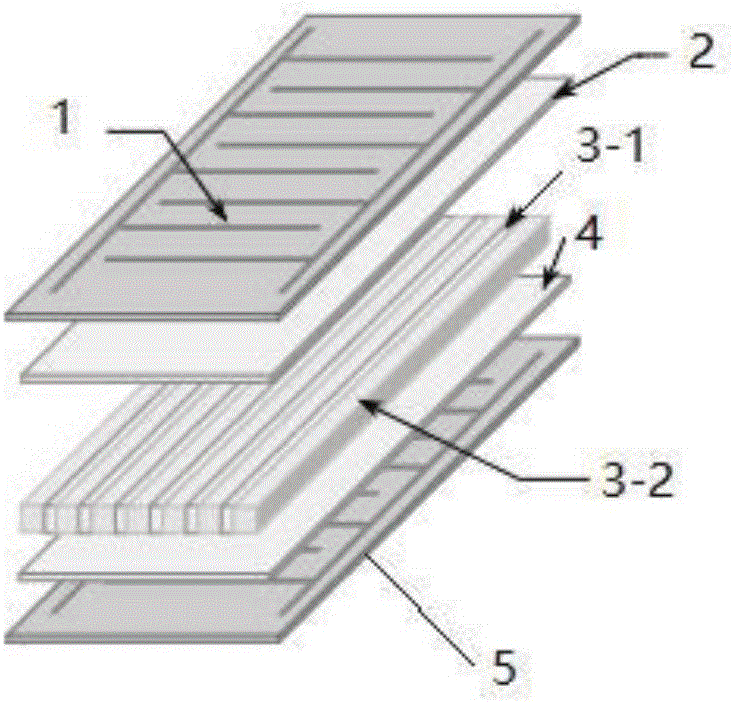

Interdigitated electrodes piezoelectric fiber composite material and preparation method therefor

A technology of piezoelectric fibers and composite materials, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, etc., can solve the problems of low utilization rate of polarization electric field, achieve convenient processing, simple operation, and improve driving deformation. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Step (1): Cut the PZT piezoelectric ceramic block (27*7*0.8mm) by cutting method, and prepare the piezoelectric ceramic fiber array. In the piezoelectric ceramic fiber array, the piezoelectric ceramic fiber width is 250 μm, and the fiber spacing 80μm;

[0060] Step (2):

[0061] Step (2-1): barium titanate modification:

[0062] 10g nano barium titanate particles (particle size is 90~100nm), put into the hydrogen peroxide aqueous solution (30wt%) ultrasonic dispersion, reflux 6 hours at 106 degree centigrade under magnetic sub-stirring, centrifugal separation, dry 12h; The product after drying (hydroxylation treatment The final nano-barium titanate) was then immersed in 0.1mol / L dopamine aqueous solution and stirred at 60 degrees Celsius for 10 hours, then centrifuged and dried for 24 hours to obtain dopamine-modified nano-barium titanate powder (about 9g).

[0063] Step (2-2): modified polymer preparation:

[0064] Then the modified nano-barium titanate obtained in ...

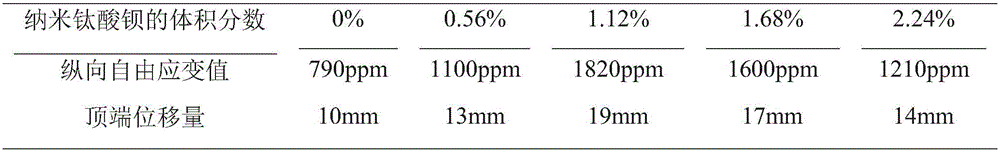

Embodiment 2

[0071] The difference from Example 1 is that the volume fraction of nano barium titanate is 1.12% (based on the volume of the cured product after the modified polymer solution is cured). The performance test can be carried out on the material prepared in this embodiment, and the results are shown in Table 1.

Embodiment 3

[0073] The difference from Example 1 is that the volume fraction of nano barium titanate is 1.68% (based on the volume of the cured product after the modified polymer solution is cured). The performance test can be carried out on the material prepared in this embodiment, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com