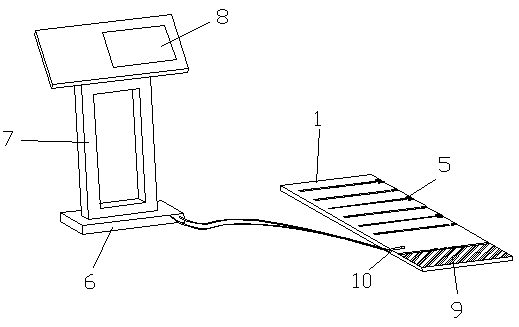

A luminous standing long jump test device

A test device and long jump technology, applied in jumping equipment, sports accessories, gymnastics equipment, etc., can solve the problems of weak protection of knee joints, no luminous function, etc., achieve superior mechanical properties and friction characteristics, not easy to deform, Effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

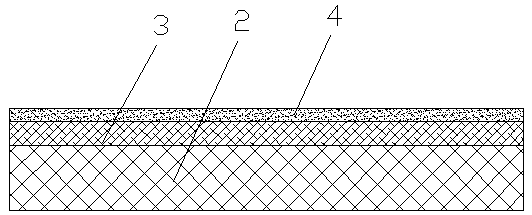

[0029]A luminous standing long jump test device, comprising a test board 1 and a display, the test board 1 includes a steel plate 2 and a composite layer fixed on the steel plate 2, the composite layer is composed of an elastic layer 3 and a luminous paint layer 4 arranged on the elastic layer 3 , the composite layer is prepared by the following method: Step 1. Take phenolic resin, add 2% by weight of boric acid, heat up to 102°C and keep it for 40min, after vacuum dehydration, add hydrolyzed silane coupling agent, and heat up to 100°C Keep at ℃ for 2.5h, after cooling, the modified phenolic resin A is prepared; take another phenolic resin and dissolve it in methanol, add 5% silver nitrate and 10% polyethylene glycol by weight of the phenolic resin, stir magnetically, and After heating at a rate of 5°C / min to 200°C for 10 minutes, continue to heat at this rate to 800°C for 1 hour to prepare modified phenolic resin B; : Mix evenly at a weight ratio of 1 to prepare a phenolic re...

Embodiment 2

[0036] A luminous standing long jump test device, comprising a test board 1 and a display, the test board 1 includes a steel plate 2 and a composite layer fixed on the steel plate 2, the composite layer is composed of an elastic layer 3 and a luminous paint layer 4 arranged on the elastic layer 3 , the composite layer is prepared by the following method: Step 1. Take phenolic resin, add 0.5% by weight of boric acid, heat up to 95°C and keep for 30min, after vacuum dehydration, add hydrolyzed silane coupling agent, and heat up to 85°C Keep at ℃ for 2h, after cooling, the modified phenolic resin A is obtained; take another phenolic resin and dissolve it in methanol, add silver nitrate and 13% polyethylene glycol which account for 2% of the weight of the phenolic resin, stir magnetically, and then dissolve the phenolic resin at 7 After heating at a rate of °C / min to 160 °C for 12 minutes, continue to heat at this rate to 750 °C for 1.5 h to obtain modified phenolic resin B; : Mix...

Embodiment 3

[0043] A luminous standing long jump test device, comprising a test board 1 and a display, the test board 1 includes a steel plate 2 and a composite layer fixed on the steel plate 2, the composite layer is composed of an elastic layer 3 and a luminous paint layer 4 arranged on the elastic layer 3 , the composite layer is prepared by the following method: Step 1. Take phenolic resin, add 1.3% by weight of boric acid, heat up to 105°C and keep it for 10min, after vacuum dehydration, add hydrolyzed silane coupling agent, and heat up to 95°C Keep at ℃ for 1.0h, and after cooling, the modified phenolic resin A is obtained; another phenolic resin is dissolved in methanol, and silver nitrate and 11% polyethylene glycol are added, which account for 2.5% of the weight of the phenolic resin. After magnetic stirring, the After heating at a rate of 6°C / min to 180°C for 15 minutes, continue to heat at this rate to 700°C for 2.0 hours to obtain modified phenolic resin B; modify phenolic resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com