Carbon fiber composite and application thereof

A composite material and carbon fiber technology, applied to loose filter material filters, filtration separation, membrane filters, etc., can solve the problems of prolonging the treatment time of filtered water and low residual chlorine removal capacity, and improve the residual chlorine removal capacity , filter fully and more thoroughly, and prolong the effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

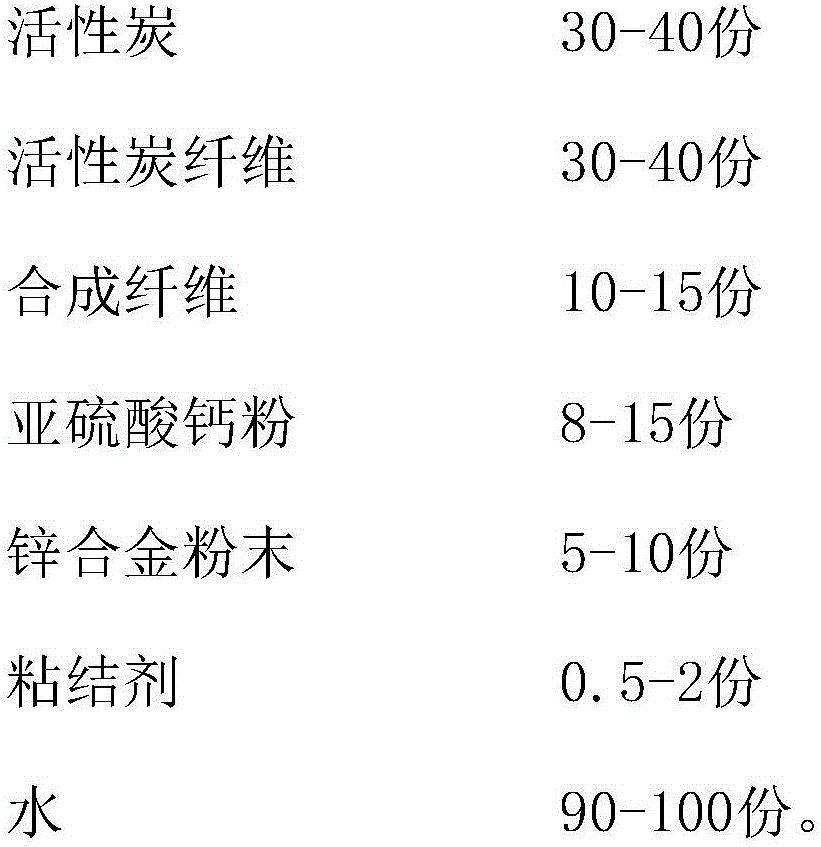

[0038] A filter element is made of carbon fiber composite material, and the carbon fiber composite material is prepared from the following components in parts by weight:

[0039]

[0040] The manufacturing process of the filter element includes the following steps:

[0041] 1) Grinding activated carbon, activated carbon fiber, synthetic fiber, calcium sulfite powder, and zinc alloy powder respectively, and sieving through 100 meshes;

[0042] 2) According to the proportioning ratio, prepare the sieved activated carbon, activated carbon fiber, synthetic fiber, calcium sulfite powder, zinc alloy powder, add polyvinyl acetate and water and mix evenly to obtain a mixed slurry;

[0043] 3) placing the mixed slurry obtained in step 2) in a molding device, and processing it into a filter element semi-finished product;

[0044] 4) Put the filter element semi-finished product that step 3) obtains into the centrifuge, the centrifuge rotation speed is 1500r / min, dehydration and dryin...

Embodiment 2

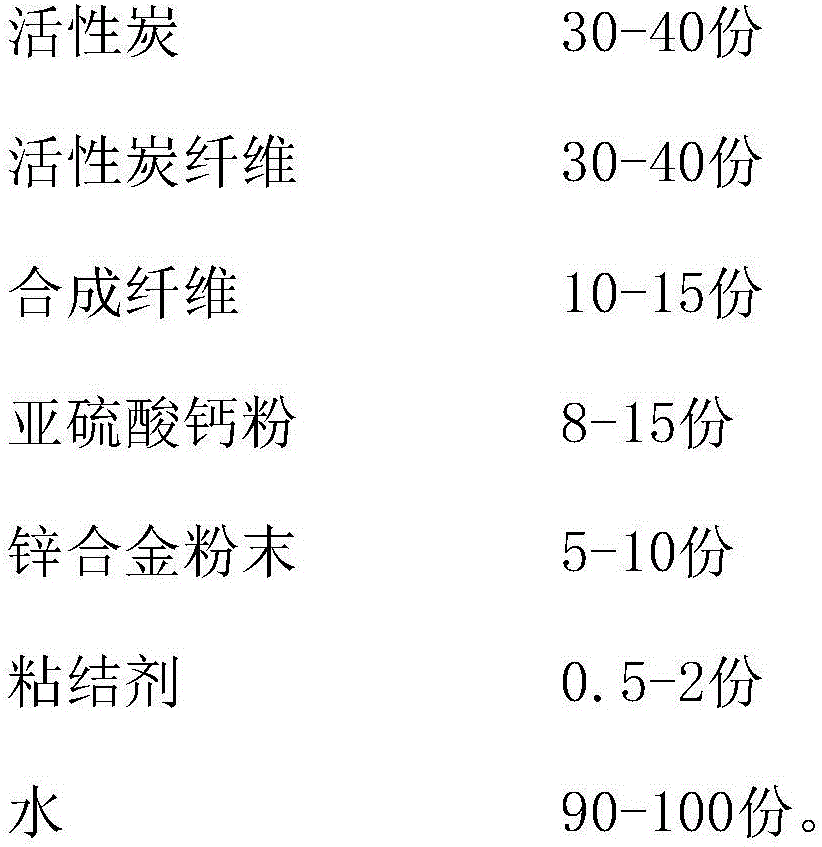

[0047] A filter element is made of carbon fiber composite material, and the carbon fiber composite material is prepared from the following components in parts by weight:

[0048]

[0049] The manufacturing process of the filter element includes the following steps:

[0050] 1) Grinding activated carbon, activated carbon fiber, synthetic fiber, calcium sulfite powder, and zinc alloy powder respectively, and sieving through 200 meshes;

[0051] 2) Prepare sieved activated carbon, activated carbon fiber, synthetic fiber, calcium sulfite powder, zinc alloy powder according to the proportion, add vinyl acetate and water and mix evenly to obtain a mixed slurry;

[0052] 3) placing the mixed slurry obtained in step 2) in a molding device, and processing it into a filter element semi-finished product;

[0053] 4) Put the filter element semi-finished product that step 3) obtains into the centrifuge, the centrifuge rotation speed is 1500r / min, dehydration and drying;

[0054] 5) Fi...

Embodiment 3

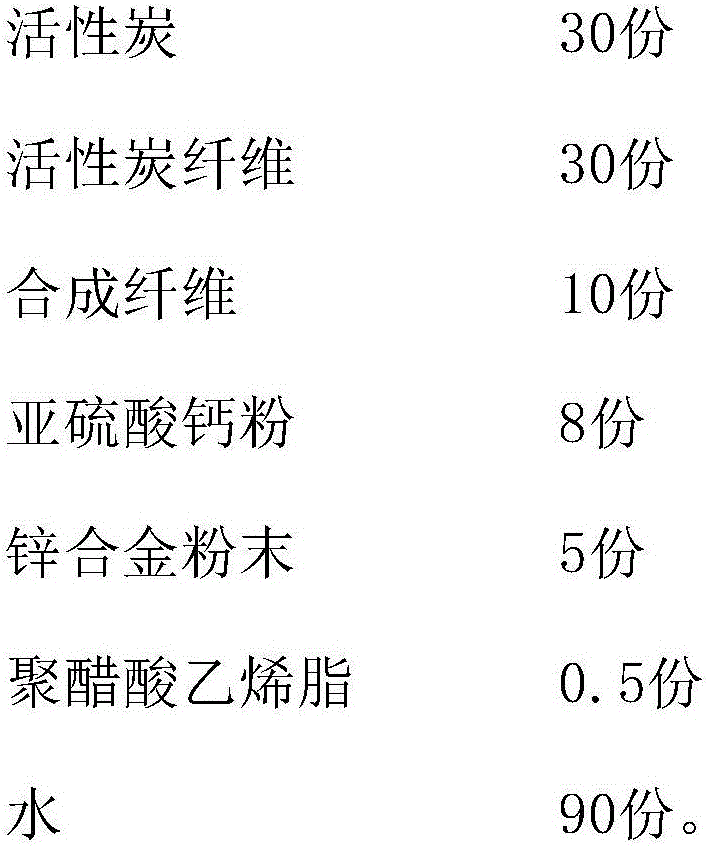

[0056] A filter element is made of carbon fiber composite material, and the carbon fiber composite material is prepared from the following components in parts by weight:

[0057]

[0058] The manufacturing process of the filter element includes the following steps:

[0059] 1) Grinding activated carbon, activated carbon fiber, synthetic fiber, calcium sulfite powder, and zinc alloy powder respectively, and sieving through 160 meshes;

[0060] 2) Prepare sieved activated carbon, activated carbon fiber, synthetic fiber, calcium sulfite powder, zinc alloy powder according to the proportion, add polyvinyl alcohol pyrrolidone and water and mix evenly to obtain a mixed slurry;

[0061] 3) placing the mixed slurry obtained in step 2) in a molding device, and processing it into a filter element semi-finished product;

[0062] 4) Put the filter element semi-finished product that step 3) obtains into the centrifuge, the centrifuge rotation speed is 1500r / min, dehydration and drying;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com