High-weather-resistance gas protection welding wire with excellent weldability

A gas-shielded welding wire and weldability technology, applied in the field of high-weather-resistant gas-shielded welding wire, can solve the problems of poor welding processability, difficult spreading of molten metal, slag inclusion, etc., to achieve excellent weld formability, improve arc stability, reduce welding cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with preferred embodiments.

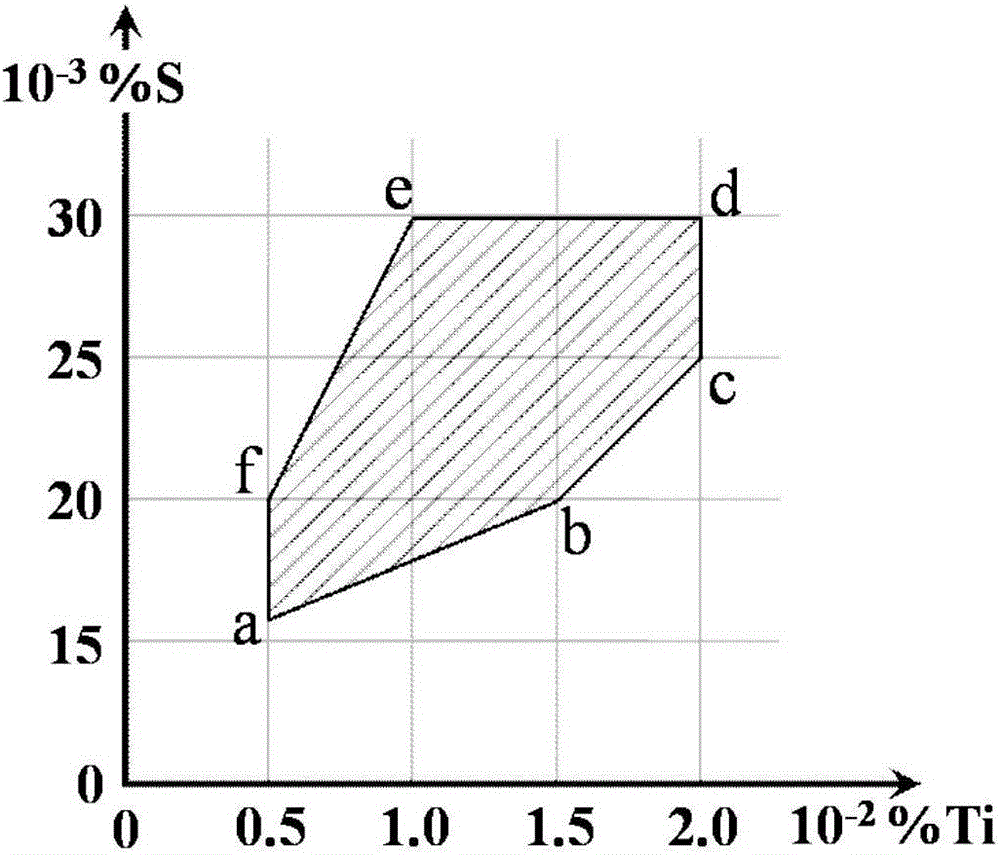

[0029] It is smelted according to the target composition and cast into steel ingots. The steel ingot is homogenized and processed into wire rod; then it is made into welding wire through softening treatment, pickling, wire drawing, copper plating, coiling and other processes. The chemical composition of the welding wire is shown in Attached Table 1. figure 1 shown.

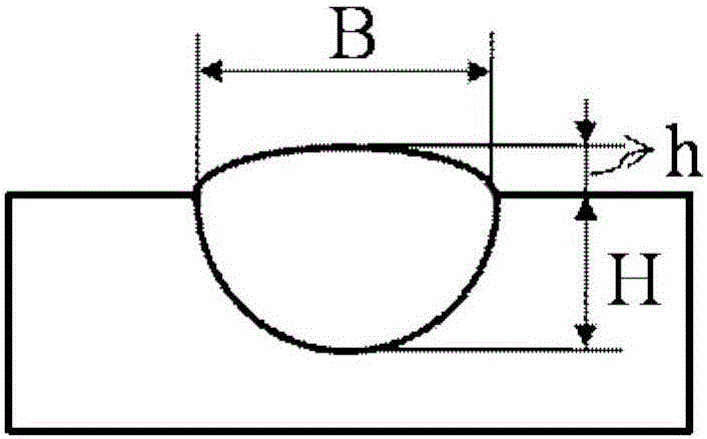

[0030] The welding wire adopts the welding polarity of DC reverse connection, matching 100% CO 2 or Ar+20%CO 2 It can be used as a shielding gas for welding. At the same time, it can match the current of 200A to 350A and the voltage of 22V to 35V for welding. The performance test of deposited metal is carried out according to the national standard. The welding process performance test adopts the method of surfacing welding on the surface of the flat plate, and records the welding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com