Drilling wastewater treatment device

A technology for treating equipment and drilling wastewater, applied in mining wastewater treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Problems such as poor performance under high load, to achieve the effect of stable physical form, better effect, and improved ability to resist high load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

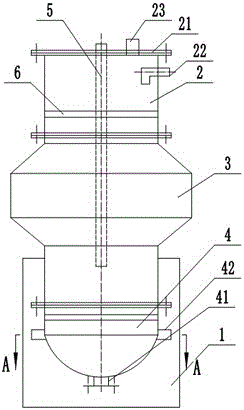

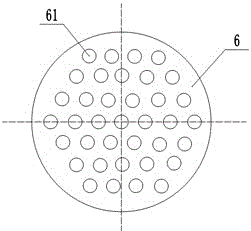

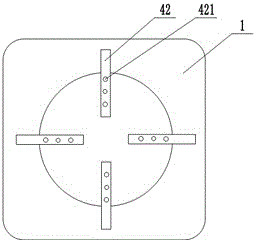

[0023] The reference signs in the drawings of the description include: skirt seat 1, upper tank body 2, upper sealing plate 21, outlet pipe 22, exhaust pipe 23, middle tank body 3, lower tank body 4, water inlet pipe 41, aeration pipe 42. Aeration hole 421, sludge adding pipe 5, water distribution pipe 6, water distribution hole 61.

[0024] The embodiment is basically as attached figure 1 Shown:

[0025] The drilling wastewater treatment equipment in this scheme consists of a tank body and a support device, and the belonging tank body is installed on the equipment support. The tank body includes an upper tank body 2, a middle tank body 3 and a lower tank body 4 from top to bottom, and the upper tank body 2, the middle tank body 3 and the lower tank body 4 are connected by flanges; wherein the upper tank body 2 and the lower tank body The tank body 4 is all cylindrical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com