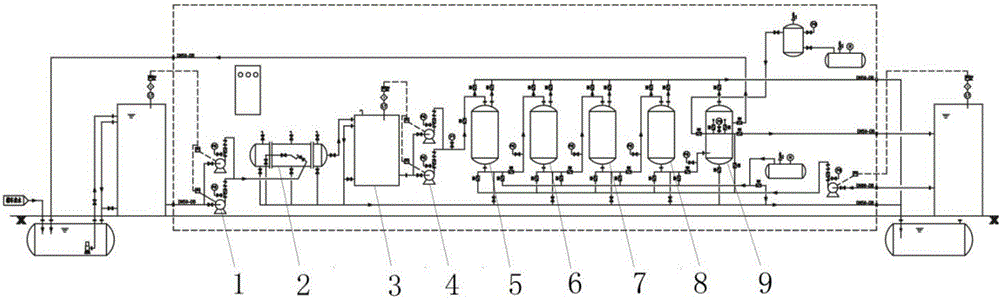

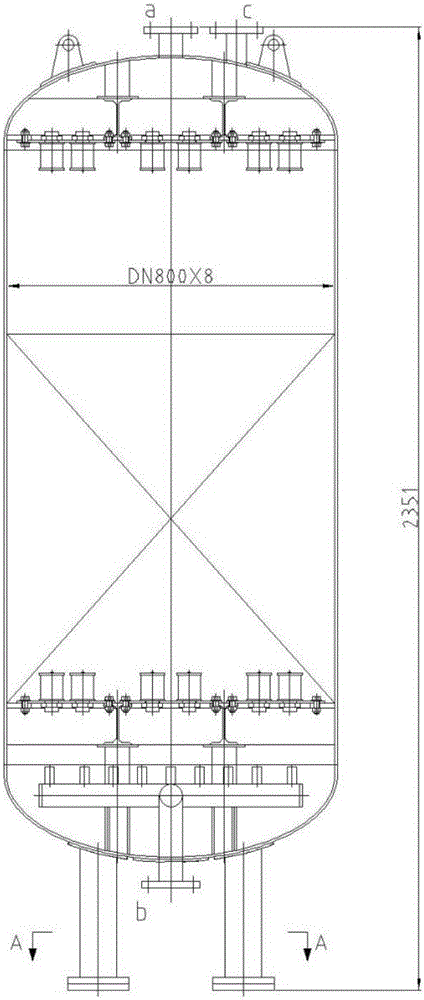

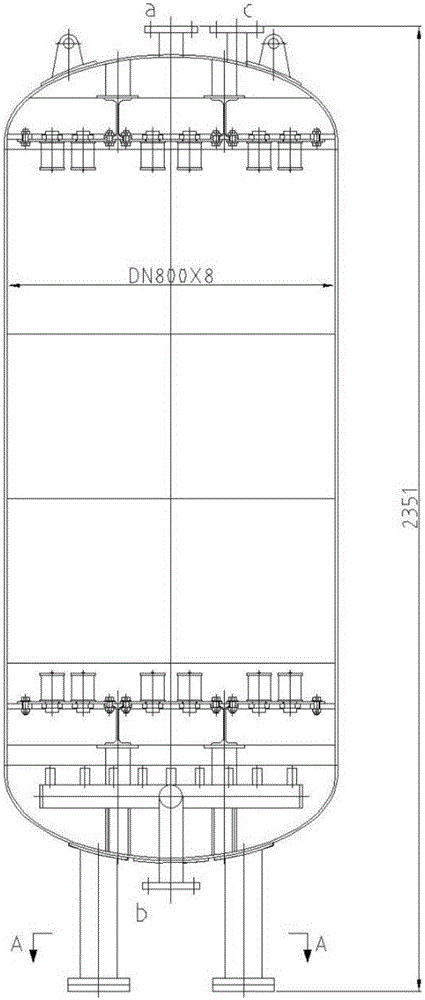

Microfiltration membrane oil filed sewage processing device and processing method

A technology for oilfield sewage and treatment equipment, which is applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., which can solve the problems of decreased membrane flux, low treatment accuracy, and formation of filter cake layers To achieve the effect of streamlining the process, ensuring the effect of backwashing and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] Experimental conditions: The injection water quality of many oil production fields in Yanchang Oilfield was significantly exceeded due to the limitation of the treatment effect of the sewage treatment process of the joint station. It is planned to build a microfiltration membrane oilfield sewage treatment integrated skid at the 1876 treatment station of Dingbian Oil Production Plant The device was installed to conduct research on sewage treatment technology, and the experimental results are shown in Table 1:

[0072] Table 1 Particle size distribution of suspended solids in effluent water samples

[0073]

[0074]

[0075] It can be seen from Table 1 that the particle size distribution of suspended solids in oilfield produced water treated by the microfiltration membrane sewage treatment device is between 91.28 and 955.4 nm, and the median particle size of suspended solids is less than 1 μm. This index has reached Requirements of "Injection Water Quality Indicator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com