Polyurethane insulation material

A thermal insulation material and polyurethane technology, which is applied in the field of thermal insulation materials, can solve the problems of atmospheric ozone layer destruction, dimensional stability, and the performance of sound insulation and heat insulation cannot meet living requirements, and achieves low cost, good thermal insulation effect, and high-efficiency flame retardant ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

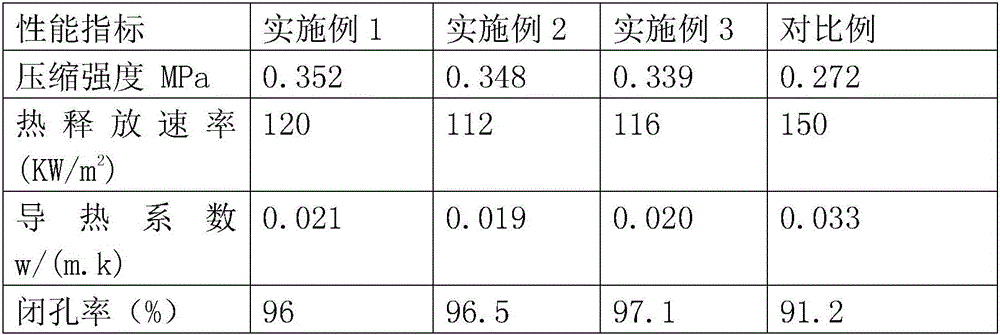

Examples

Embodiment 1

[0023] A polyurethane thermal insulation material is made by foaming raw materials in the following proportions by weight:

[0024] Diphenylmethane diisocyanate 60kg, plant fiber-based polyether polyol 40kg, vegetable oil-based polyether polyol 30kg, catalyst 1kg, organic flame retardant 1kg, blowing agent 0.5kg, silicone oil 1kg, deionized water 6kg.

[0025] The plant fiber-based polyether polyol is a polyether polyol made from agricultural and forestry waste, with a viscosity of 2800 mPa·s and an average functionality of 4.

[0026] The vegetable oil-based polyether polyol is a polyether polyol made from waste oil or non-edible oil, with a viscosity of 2800 mPa·s and an average functionality of 4.5.

[0027] The catalyst is N,N-dimethylcyclohexylamine.

[0028] The organic flame retardant is a phosphorus-nitrogen intumescent flame retardant.

[0029] The blowing agent is cyclopentane.

[0030] The preparation method of above-mentioned polyurethane insulation material com...

Embodiment 2

[0036] A polyurethane thermal insulation material is made by foaming raw materials in the following proportions by weight:

[0037] 70kg of diphenylmethane diisocyanate, 50kg of plant fiber-based polyether polyol, 40kg of vegetable oil-based polyether polyol, 2kg of catalyst, 2kg of organic flame retardant, 0.8kg of foaming agent, 2kg of silicone oil, and 7kg of deionized water.

[0038] The plant fiber-based polyether polyol is a polyether polyol made from agricultural and forestry waste, with a viscosity of 2800 mPa·s and an average functionality of 4.5.

[0039] The vegetable oil-based polyether polyol is a polyether polyol made from waste oil or non-edible oil, with a viscosity of 2800 mPa·s and an average functionality of 4.8.

[0040] The catalyst is N,N-dimethylcyclohexylamine.

[0041] The organic flame retardant is a phosphorus-nitrogen intumescent flame retardant.

[0042] The blowing agent is cyclopentane.

[0043] The preparation method of above-mentioned polyur...

Embodiment 3

[0049] A polyurethane thermal insulation material is made by foaming raw materials in the following proportions by weight:

[0050] 80kg of diphenylmethane diisocyanate, 60kg of plant fiber-based polyether polyol, 50kg of vegetable oil-based polyether polyol, 3kg of catalyst, 3kg of organic flame retardant, 1kg of foaming agent, 3kg of silicone oil, and 8kg of deionized water.

[0051] The plant fiber-based polyether polyol is a polyether polyol made from agricultural and forestry waste, with a viscosity of 2800 mPa·s and an average functionality of 5.

[0052] The vegetable oil-based polyether polyol is a polyether polyol made from waste oil or non-edible oil, with a viscosity of 2800 mPa·s and an average functionality of 5.

[0053] The catalyst is N,N-dimethylcyclohexylamine.

[0054] The organic flame retardant is a phosphorus-nitrogen intumescent flame retardant.

[0055] The blowing agent is cyclopentane.

[0056] The preparation method of above-mentioned polyurethane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com