High-fluidity elastomer and preparation method thereof

A high fluidity, elastomer technology, applied in the field of thermoplastic elastomers and their preparation, can solve the problems of high viscosity and poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

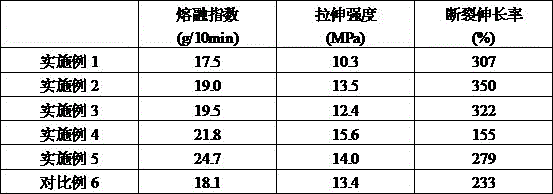

Examples

Embodiment 1

[0026] All the materials involved were placed in a vacuum drying oven and dried for 8 hours for later use. First, 10 kg of elastomers were crushed using the low-temperature liquid nitrogen freezing and crushing equipment owned by the company, and then 100 g of lubricants (75 g hard Zinc fatty acid and 25g solid paraffin mixture), 10g Ca-Zn stabilizer are added to the high-speed mixer that has been preheated to a certain temperature and mixed evenly, then slowly add 100g plasticizer (80g phthalic acid di octyl ester and 20g dioctyl sebacate). Due to the internal heat generated by high-speed mixing, add 5g of n-octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate and the mixing temperature will rise to 100°C~105°C. At this time, Dioctyl phthalate and dioctyl sebacate are absorbed by the elastomer powder, resulting in swelling, and other ingredients are also uniformly dispersed in the mixture. Then put the material into the cooling mixer, when it drops to 50°C, add 50g of ...

Embodiment 2

[0028]All the materials involved were placed in a vacuum drying oven and dried for 8 hours for later use. First, 10 kg of elastomers were crushed using the low-temperature liquid nitrogen freezing and crushing equipment owned by the company, and then 500 g of lubricants (275 g hard Zinc fatty acid and 225g solid paraffin mixture), 50g Ca-Zn stabilizer were added to the high-speed mixer that has been preheated to a certain temperature and mixed evenly, then slowly added 1kg plasticizer (800g phthalic acid di octyl ester and 200g dioctyl sebacate). Due to the internal heat generated by high-speed mixing, add 5g of n-octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate and the mixing temperature will rise to 100°C~105°C. At this time, Dioctyl phthalate and dioctyl sebacate are absorbed by the elastomer powder, resulting in swelling, and other ingredients are also uniformly dispersed in the mixture. Then put the material into the cooling mixer, when it drops to 50°C, add 50...

Embodiment 3

[0030] All the materials involved were placed in a vacuum drying oven and dried for 8 hours for later use. First, 10 kg of elastomers were crushed using the low-temperature liquid nitrogen freezing and crushing equipment owned by the company, and then 500 g of lubricants (275 g hard Zinc fatty acid and 225g solid paraffin mixture), 50g Ca-Zn stabilizer are added to the high-speed mixer that has been preheated to a certain temperature and mixed evenly, then slowly add 100g plasticizer (80g phthalic acid di octyl ester and 20g dioctyl sebacate). Due to the internal heat generated by high-speed mixing, add 10g of n-octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate and the mixing temperature will rise to 100°C~105°C. At this time, Dioctyl phthalate and dioctyl sebacate are absorbed by the elastomer powder, resulting in swelling, and other ingredients are also uniformly dispersed in the mixture. Then put the material into the cooling mixer, when the temperature drops to 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com