Patents

Literature

33results about How to "Strong internal lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite polypropylene wax used for plastic and preparation method of composite polypropylene wax

The invention relates to a production method for composite polypropylene wax used for plastic. The composite polypropylene wax comprises polypropylene low polymers, Fischer-tropsch wax or microcrystalline wax and industrial hydrogenated oil, and has the properties that the softening point is 100 DEG C or above, and the average molecular weight ranges from 1500 to 3000. As an excellent dispersing agent, on the aspects of color master production and pigment dispersion, the composite polypropylene wax produced through the method has the advantages that effective molecular weights are concentrated, wherein the molecular weights are narrowly distributed and concentrated, and therefore the dispersion effect and the coloring force are easily improved, and relatively speaking, the addition amount can be decreased under the certain dispersion requirement; the excellent heat resistance and the excellent thermal stability are achieved; the melting point and the viscosity matching are moderate, and the shearing force is facilitated, wherein the softening point is 110 DEG C, the high viscosity is 150 CP / 140 DEG C, produced color master particles have high intermiscibility and mobility and moderate in viscosity, the shearing force is increased, and dispersity is improved.

Owner:扬州罗兰新材料有限公司

Preparation method for three-layer co-extruded composite high barrier blown film

InactiveCN104385565AReduce melt viscosityImprove melt fluidityLow-density polyethyleneLinear low-density polyethylene

The invention relates to a preparation method for a three-layer co-extruded composite high barrier blown film. The method includes: taking polyvinylidene chloride as the basic raw material, adding metallocene linear low density polyethylene, an ethylene-octene block copolymer, tributyl citrate, a rare earth calcium zinc composite stabilizer and butyl stearate, and carrying out a three-layer coextrusion blow molding process so as to obtain the film. The formula of the film surface layer involves: 80-88 parts by weight of metallocene linear low density polyethylene and 12-20 parts by weight of the ethylene-octene block copolymer. The interlayer comprises: 77-85 parts by weight of polyvinylidene chloride, 12-18 parts by weight of tributyl citrate, 2-3 parts by weight of the rare earth calcium zinc composite stabilizer, and 1-2 parts by weight of butyl stearate. The film prepared by the method provided by the invention has excellent oxygen obstruction and aqueous vapor permeation performance, good physical and mechanical properties and sanitation properties, and is suitable for packaging of cooked food, oily food, chilled fresh meat, dairy products, tea and drugs, etc.

Owner:FUJIAN NORMAL UNIV

High-density polyethylene modified material and preparation method thereof

The invention relates to a polyethylene modified material and a preparation method thereof, and in particular relates to a high-density polyethylene modified material and a preparation method thereof, and belongs to the plastic modification field. The invention discloses the high-density polyethylene modified material and the preparation method thereof, wherein the high-density polyethylene modified material is composed of the following raw materials in parts by weight: 50-70 parts of HDPE, 1-4 parts of polyethylene-octene elastomer, 0.01-0.5 part of polyurethane resin, 10-25 parts of calcium carbonate, 10-20 parts of metallocene modified polyethylene, 2-8 parts of dispersant, 0.1-5 parts of ultraviolet absorber and 0.5-3 parts of magnesium hydroxide. The preparation method comprises five steps of metering, mixing, extruding, drawing and cooling, and drying and pelletizing. The preparation method has excellent anti-aging capacity and anti-impact capacity, and is high in tenacity, not prone to change color and high in vapor infiltration preventing capacity, and is mainly applied to blowing middle and top grade food packages.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Special material of multilayer co-extrusion film produced by recycled PET bottle flakes and recycled LDPE alloy and preparation method thereof

The invention discloses a special material of a multilayer co-extrusion film produced by recycled PET bottle flakes and recycled LDPE alloy. The special material of the multilayer co-extrusion film is prepared from the following components: 60-85 part by weight of recycled PET bottle flakes, recycled LDPE reclaim particles, 3-15 part by weight of EVA, 3-10 part by weight of graft POE, 0.1-0.5 part by weight of oxidized PE wax, 0.1-0.2 part by weight of PPA, 0.1-0.3 part by weight of GMS and 0.1-0.3 part by weight of chain extender PMDA. The special material of the multilayer co-extrusion film solves the tearing and rupture phenomena of recycled plastic extrusion films and can partly replace fresh material PET and PE alloy.

Owner:四川塑金科技有限公司

PVC high-molecular waterproof coiled material

A disclosed PVC high-molecular waterproof coiled material is composed of the following raw materials in parts by weight: 10-20 parts of polyvinyl chloride, 5-10 parts of oxidized polyethylene, 5-10 parts of polyethylene, 20-40 parts of heavy calcium carbonate, 5-10 parts of stearic acid, 2-5 parts of a stabilizing agent, 3-7 parts of barium sulfate, 15-30 parts of industrial white oil, 0.5-2 parts of a filler, and 0.1-0.5 part of a defoaming powder. The beneficial effects comprise that the coiled material is prepared by taking PVC material as a main material and matching with multiple auxiliary materials and performing a high temperature reaction. The coiled material is good in flexibility, high in elongation percentage, resistant to corrosion and resistant to acids and alkalis, and is improved in service life.

Owner:XIAMEN LIKASAM WATERPROOF ENG

Formula and production process of oil-water type anti-slip material

The invention relates to the technical field of shoe sole anti-slip technology, in particular to a formula of an oil-water type skid-resistant material. The antiskid material is prepared from the following raw materials in parts by weight: N230S (JSR) nitrile butadiene rubber, 7030 (LG) nitrile butadiene rubber, brominated butyl rubber, carbon black, acetyl tributyl citrate, magnesium oxide, 997#zinc oxide, stearic acid, C9 resin and a lubricant. Nitrile butadiene rubber is selected as main rubber, so that on one hand, the oil resistance of the rubber material is improved; on the other hand,brominated butyl rubber is added to interfere in the normal crosslinking of the rubber and improve the hysteresis of the rubber. The surfaces of the carbon black and the brominated butyl rubber have polar groups, so that the antiskid performance of the natural rubber sole can be further improved. The C9 resin is added into the rubber, so that the free volume of a molecular chain in the vulcanizedrubber is reduced, the friction among chain segments, between fillers and between the chain segments and the carbon black is increased, and the lag is enhanced; therefore, the wet skid resistance of the nitrile rubber can be further enhanced.

Owner:ZHEJIANG AOKANG SHOES

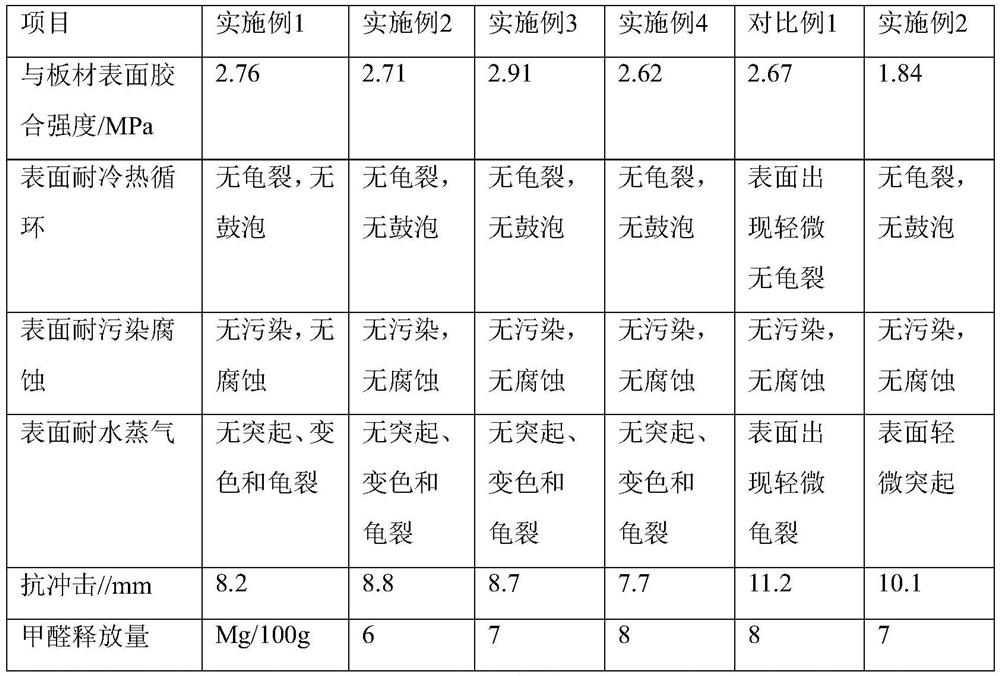

Weather-proof decorative paper and preparation method thereof

PendingCN112301797AGood weather resistanceAccelerated corrosionSpecial paperNon-macromolecular organic additionWeather resistanceProcess engineering

The invention relates to the technical field of decorative paper, in particular to weather-proof decorative paper and a preparation method thereof. The decorative paper comprises a base paper layer, an impermeable adhesive layer coating the surface of the base paper layer and a protective adhesive layer attached to the upper surface of the impermeable adhesive layer, and the base paper layer is provided with an ink pattern layer. The decorative paper has excellent weather resistance, corrosion resistance and mechanical properties, and is long in service life, good in appearance effect and highin practicability. The preparation method of the weather-proof decorative paper is simple, efficient, convenient to operate and control, stable in product quality and beneficial to industrial production.

Owner:GUANGDONG FUMEI NEW MATERIAL TECH CO LTD

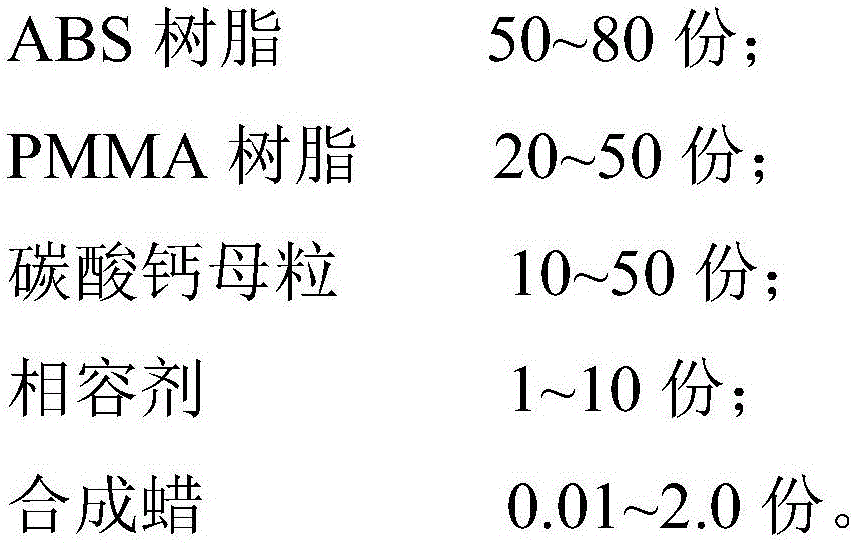

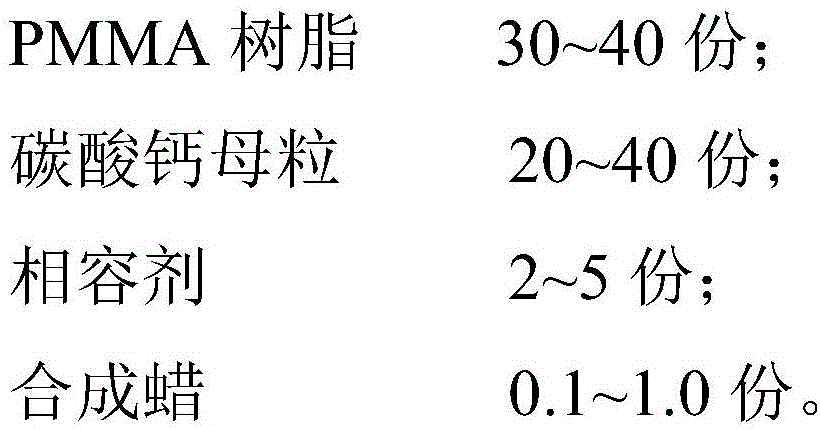

Efficient solid screw cleaning agent and preparation method thereof

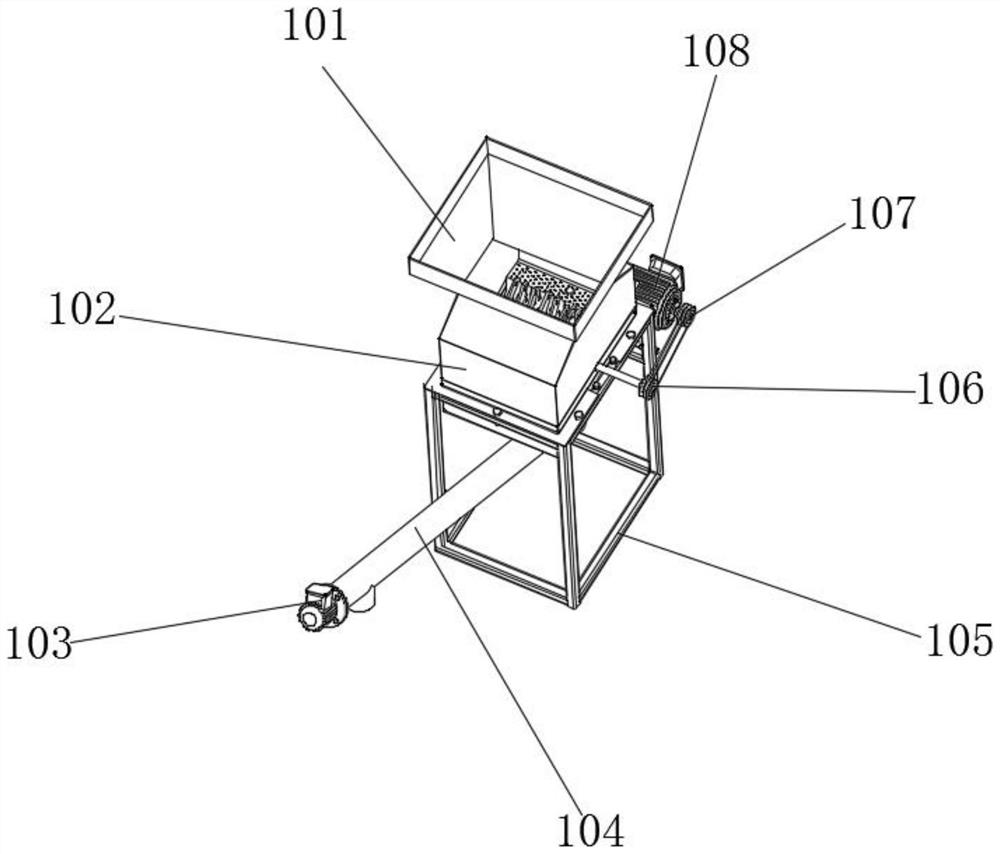

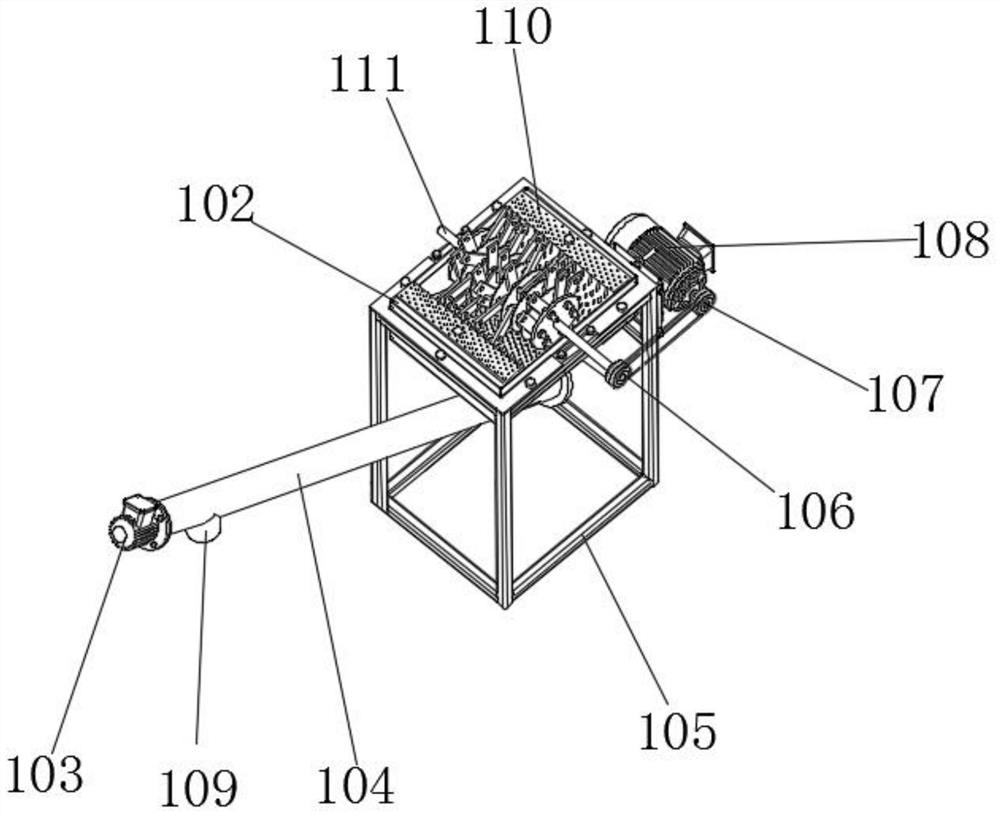

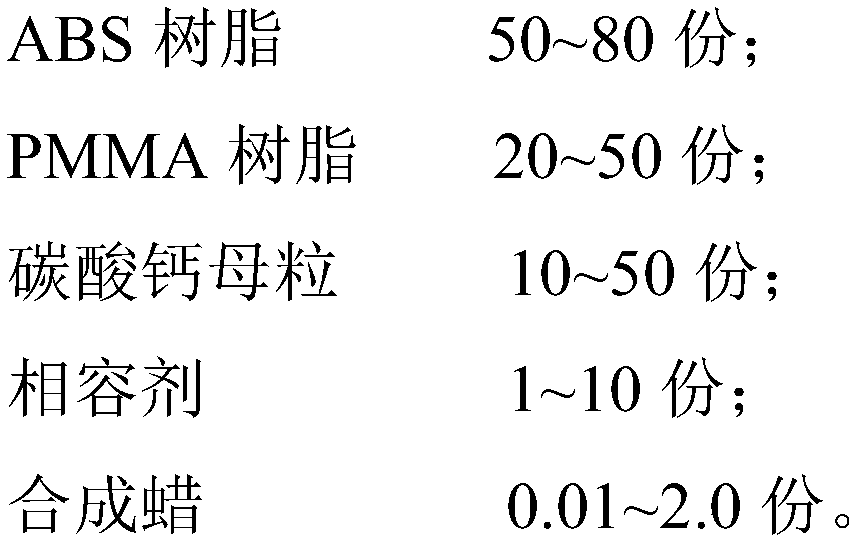

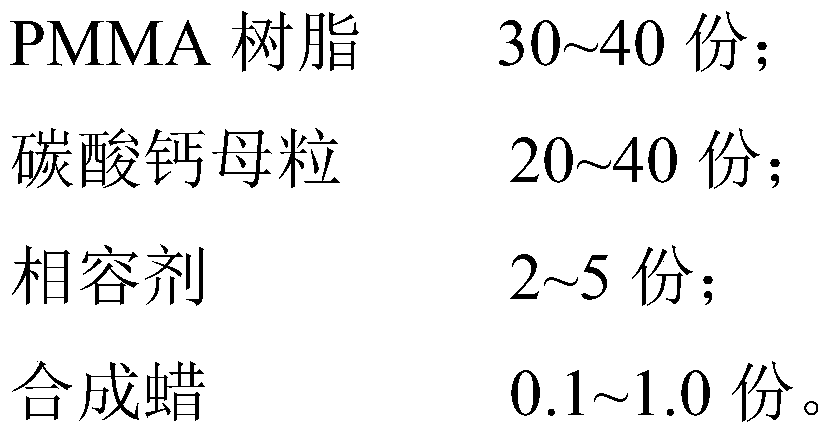

The invention discloses an efficient solid screw cleaning agent and a preparation method thereof. The efficient solid screw cleaning agent is prepared from ABS (acrylonitrile-butadiene-styrene) resin, PMMA (polymethyl methacrylate) resin, calcium carbonate masterbatch, a compatilizer and synthetic wax, wherein the cleaning capacity can be improved by means of the high-viscosity PMMA resin in the cleaning agent, compatibility between the ABS resin and the PMMA resin can be improved by means of the compatilizer, the abnormal phenomena of bar breakage and the like in an extruding granulation process are reduced, stabilization of production is facilitated, and the cleaning agent is discharged out of equipment by a follow-up material more easily during cleaning of the equipment; the capacity of the cleaning agent for cleaning residual substances can be improved by means of the synthetic wax; besides, inorganic powder is replaced with the calcium carbonate masterbatch, so that the phenomenon of powder floating is reduced, the production environment is improved, and harm of powder to the environment and the human body is reduced.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

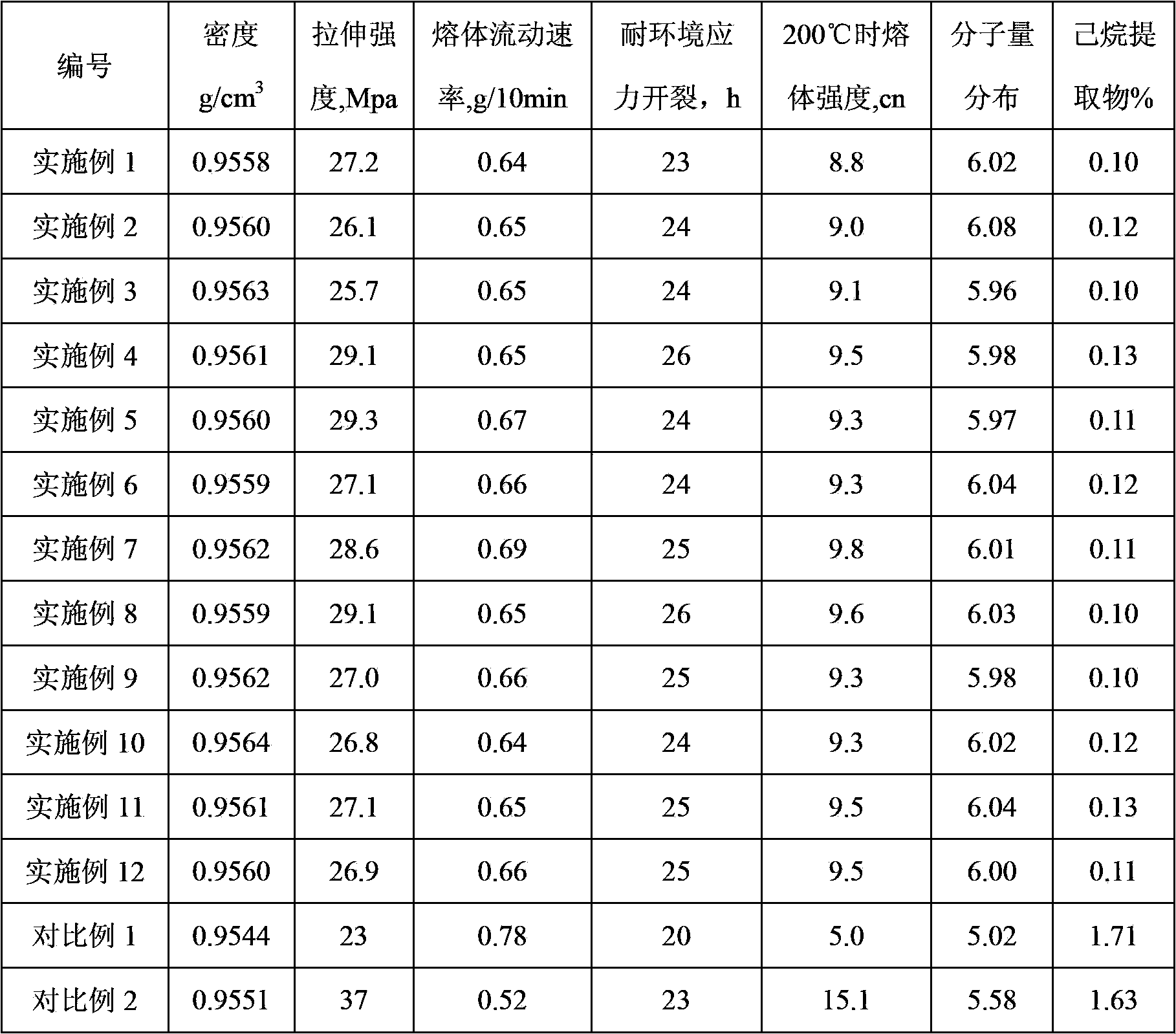

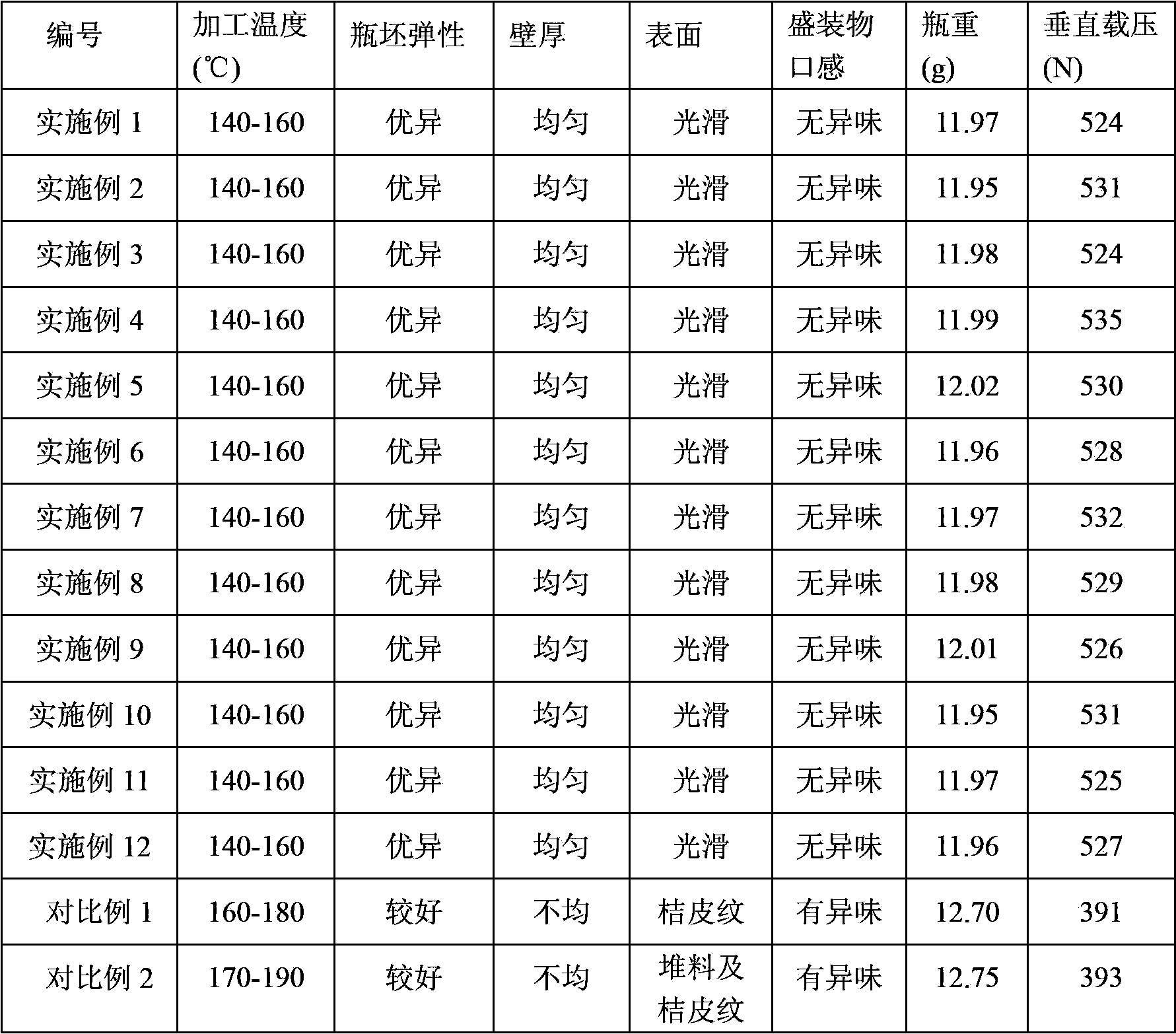

Preparation method of high density polyethylene resin special for abnormal-shape bottles

The invention relates to a preparation method of high density polyethylene resin special for abnormal-shape bottles; in a granulation workshop section of a high density polyethylene device, 0.01-0.8% by mass percentage of a composite processing additive is added for direct preparation of the high density polyethylene resin special for the abnormal-shape bottles; the composite processing additive is prepared from the following substances: by mass, 10-20% of an antioxidant, 35-50% of a lubricant, 20-30% of a fluorine elastomer and 15-20% of oxidized polyethylene wax; the resin has the characteristics of moderate melt strength and wide molecular weight distribution, and the characteristics are necessary for a special material suitable for blowing the abnormal-shape bottles; the resin has excellent processing performances, and solves the problems that: during production of the abnormal-shape bottles by use of blend resin, the produced abnormal-shape bottles have unsmooth surfaces and uneven wall thickness, articles contained in the abnormal-shape bottles may produce peculiar smell, and the like.

Owner:PETROCHINA CO LTD

High-density polyethylene (HDPE) modified material and preparation method thereof

The invention discloses a high-density polyethylene (HDPE) modified material, which is composed of the following raw materials in parts by weight: 55-65 parts of HDPE, 1-4 parts of polyethylene octylene blending elastomer, 10-20 parts of polyurethane resin, 8-15 parts of calcium carbonate powder, 8-15 parts of metallocene modified polyethylene, 2-8 parts of polyethylene wax, 1-5 parts of light stabilizer, and 0.1-3 parts of ultraviolet light absorber. The invention further discloses a preparation method of the HDPE modified material. The preparation method comprises the steps of mixing, extruding, cooling, granulating and the like. The HDPE modified material disclosed by the invention has ageing-resistant ability and impact-resistant ability, and has the advantages of being high in toughness and difficult to change colour.

Owner:CHENGDU JINHUI TECH

Anti-bite cable protective covering

The invention provides an anti-bite cable protective covering. A shell of the anti-bite cable protective covering is prepared from, by mass, 90-110 parts of polyvinyl chloride resin, 40-60 parts of calcium carbonate, 10-20 parts of o-benzene dioctyl, 11-16 parts of chlorinated paraffin, 2-4 parts of compound stabilizer, 0.4-0.8 part of stearic acid and 3-5 parts of anti-mouse-bite master batch 9074-FT-40. The anti-bite cable protective covering is environmentally friendly and safe in formula, is free of toxin and harms to human bodies and the environment, meets the ecological requirements, and meanwhile well achieves a mouse bite prevention function; the prepared cable protective covering is firm and durable, resistant to aging and higher in flexibility and can better achieve a cable core protecting effect.

Owner:ZHEJIANG COMMSPACE CABLE

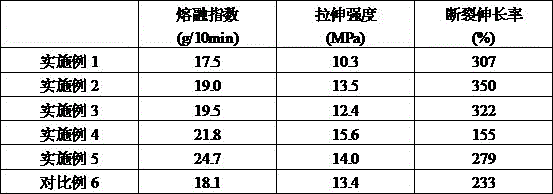

High-fluidity elastomer and preparation method thereof

InactiveCN106221109AHigher than the surfaceImprove the effect of surface modificationElastomerHeat stability

The invention discloses a high-fluidity elastomer and a preparation method thereof. A low-temperature liquid nitrogen refrigeration smashing device of the company is utilized to smash an elastomer, a lubricating agent, a plasticizer, a function additive and other assistants are utilized to conduct surface modification on smashed elastomer particles, the surface energy of the particles is reduced, the friction among the particles is reduced, and the lubricity of the particle surfaces is improved. Therefore, the elastomer has higher liquidity and excellent processing performance. The assistants in the inside do not easily migrate, the elastomer has higher heat stability and weather resistance, does not easily oxidize, is difficult to volatilize, has excellent electrical insulation properties, belongs to an environmentally friendly high-fluidityelastomer, is low in cost and suitable for large-scale industrial production, can be applied to special buffering materials, can also greatly serve as the material required for top-grade home furnishing and can be further used for efficient synergists, flame retardants and the like of high-performance foaming materials, shoe materials, top-grade hot melt adhesives and other hot melt adhesives.

Owner:广州市新稀冶金化工有限公司

Ultraviolet light curing silk-screen fission printing ink

The invention discloses ultraviolet light curing silk-screen fission printing ink. The silk-screen fission printing ink is prepared from, by weight, 30-40 parts of TPGDA, 5-10 parts of trimethylolpropane triacrylate, 5-10 parts of ethoxyquin trimethylolpropane triacrylate, 20-30 parts of epoxy resin, 20-30 parts of polyurethane resin, 4.8-7 parts of photo initiator, 0.1-0.3 part of polydimethylsiloxane and 0.3-1 part of a lubricant. The silk-screen fission printing ink has the advantages of being good in flexibility, high in adhesive force and good in wear resistance.

Owner:浙江银鹿新材料有限公司

Irradiation crosslinked low smoke halogen-free flame-retardant ethylene vinyl acetate elastomer and preparation method thereof

ActiveCN103467837AGood ozone aging resistanceAvoid stickingPlastic/resin/waxes insulatorsInsulated cablesElastomerAluminium hydroxide

The invention relates to an irradiation crosslinked low smoke halogen-free flame-retardant ethylene vinyl acetate elastomer and a preparation method thereof and in particular relates to a raw material used for preparing soft cable sheaths with oil resistance and a preparation method thereof. The irradiation crosslinked low smoke halogen-free flame-retardant ethylene vinyl acetate elastomer is prepared by mixing the raw materials including a base resin A, a base resin B, a modified resin C, aluminium hydroxide, magnesium hydroxide, zinc stearate, a lubricant, an antioxidant, a crosslinking agent and the like in a closed mixer at 130-140 DEG C and then extruding the mixture with a double-screw extruder with six temperature stages. The wires and cables prepared by adopting the elastomer have the characteristics of good softness, halogen-free flame retardance, good heat resistance (110 DEG C under the condition of long-term use), good oil and solvent resistance, good wear resistance, simplicity in processing, lower production costs and the like.

Owner:WUXI JAKE PLASTIC

Irradiation crosslinked low-smoke halogen-free flame-retardant ethylene vinyl acetate elastomer and preparation method thereof

ActiveCN103467837BGood ozone aging resistanceLow viscosityPlastic/resin/waxes insulatorsInsulated cablesElastomerAluminium hydroxide

The invention relates to an irradiation crosslinked low smoke halogen-free flame-retardant ethylene vinyl acetate elastomer and a preparation method thereof and in particular relates to a raw material used for preparing soft cable sheaths with oil resistance and a preparation method thereof. The irradiation crosslinked low smoke halogen-free flame-retardant ethylene vinyl acetate elastomer is prepared by mixing the raw materials including a base resin A, a base resin B, a modified resin C, aluminium hydroxide, magnesium hydroxide, zinc stearate, a lubricant, an antioxidant, a crosslinking agent and the like in a closed mixer at 130-140 DEG C and then extruding the mixture with a double-screw extruder with six temperature stages. The wires and cables prepared by adopting the elastomer have the characteristics of good softness, halogen-free flame retardance, good heat resistance (110 DEG C under the condition of long-term use), good oil and solvent resistance, good wear resistance, simplicity in processing, lower production costs and the like.

Owner:WUXI JAKE PLASTIC

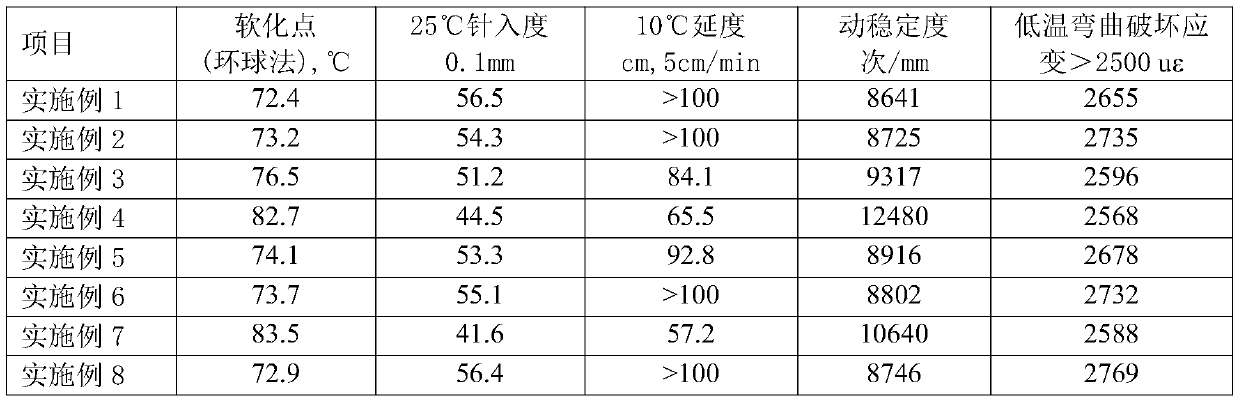

High performance composite modified asphalt, and preparation method thereof

ActiveCN109880386ASimple processImprove high temperature performanceBuilding insulationsRoad engineeringPhosphoric acid

The invention belongs to the technical field of road engineering material and environment protection, and relates to a high performance composite modified asphalt, and a preparation method thereof. The high performance composite modified asphalt is composed of, by weight, 80-95 parts of an A component and 5-20 parts of a B component; wherein the A component is composed of 79.8 to 94.8 parts of matrix asphalt, and 0.2 to 2.5 parts of polyphosphoric acid; the B composition is composed of 1 to 10 parts of recycled polyethylene wax, 0 to 8 parts of rock asphalt, 0.1 to 5 parts of a filling material, 0.5 to 8 parts of rubber, and 0 to 5 parts of extract oil. The preparation method comprises following steps: the A component and the B component are prepared respectively; the B component is addedinto the chemically modified A component, and sufficiently stirring is carried out so as to obtain the high performance composite modified asphalt. The processing technology is simple; processing temperature is low; processing time is short; production at any mixing stations can be realized; the high temperature performance reaches and even exceeds anti-rut agent adding indexes; and the low temperature performance reaches and even exceeds that of SBS modified asphalt.

Owner:云南云天化以化磷业研究技术有限公司 +1

Special self-sinking rubber pipe for aerated oxygenation and manufacturing method thereof

InactiveCN104844966ADoes not affect normal useNot easy to aging and crackingPolymer sciencePolyvinyl chloride

The invention discloses a special self-sinking rubber pipe for aerated oxygenation. The self-sinking rubber pipe comprises the following specific components in parts by weight: 88-102 parts of PVC (Polyvinyl Chloride) resin, 45-65 parts of dioctyl phthalate, 38-54 parts of heavy calcium, 1-3 parts of a calcium-zinc composite stabilizer, 8-16 parts of epoxidized soybean oil, 16-25 parts of superfine iron powder, 5-12 parts of nitrile rubber P83, 0.6-1.5 parts of an antioxidant, 3-6 parts of ACR (Acrylic Ester) resin, 0.1-1 part of an ultraviolet light absorber UV-531 and 0.3-0.8 part of PE (Poly Ethylene) wax. The invention also discloses a manufacturing method of the special self-sinking rubber pipe for the aerated oxygenation. The self-sinking rubber pipe is resistant to strong acid and strong base corrosion, unlikely to age and crack, and long in service life; the use of the self-sinking rubber pipe is not affected under high-temperature or low-temperature conditions.

Owner:淮安市绿泉工贸有限公司

Novel plastic steel door-window sectional material

The invention relates to a novel plastic steel door-window sectional material comprising the following raw materials by weight: 70-80kg of resin, 20-26kg of rock powder, 3-4kg of titanium pigment, 3-4kg of precipitant, 8-9kg of chlorinated polyethylene, 0.4-0.8kg of modified resin, 10-14g of ultramarine, 10-14g of whitening agent, 40-60g of polyethylene wax, 70-90g of stearic acid and 10-12g of ammonium polyphosphate. According to the novel plastic steel door-window sectional material, the resin is used as the main raw material, the rock powder for reducing the product cost as well as the titanium pigment, whitening agent and ultramarine achieving a whitening effect are added to ensure that the product can not turn yellow when used for a long time, and chlorinated polyethylene with impact resistance as well as PE wax and stearic acid for lubrication are added at the same time. The plastic steel door-window sectional material disclosed by the invention has relatively strong corrosion resistance, ultraviolet resistance, fire resistance, insulating property and the like, and is high in safety factor, low in cost and suitable for the level of mass consumption.

Owner:江苏荣光塑料科技发展有限公司

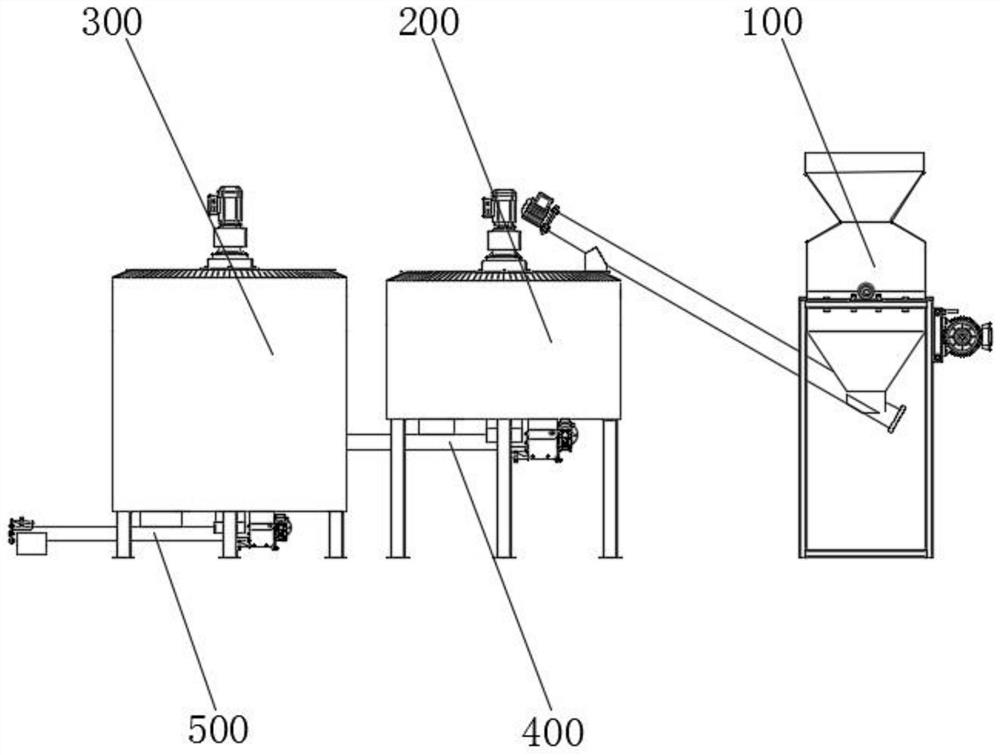

Recycling treatment method of waste plastic particles

The invention discloses a waste plastic particle recycling treatment method, which comprises the following steps: waste plastic particles can be prepared into waste plastic powder, and then the wasteplastic powder is matched with wood fiber powder, clay, a plasticizer, a stabilizer, PE wax, stearic acid, a foaming regulator, a foaming agent and a dispersing agent to prepare a wood-plastic raw material; waste plastic resources can be fully utilized, and the prepared wood-plastic material is excellent in performance; according to the recycling treatment method, recycling processing equipment isused for processing the waste plastic particles; the waste plastic particles are crushed into powder; the waste plastic powder is conveyed into a first mixing tank and uniformly mixed with a plasticizer and a stabilizer; a first mixture is prepared, and then the first mixture is transported to a second mixing tank and mixed with other raw materials to obtain wood-plastic raw materials. Accordingto the present invention, the equipment has the high automation degree, the production efficiency of the wood-plastic material is effectively improved, and the problem that the waste plastic pollutesthe environment is well solved.

Owner:亳州丰色信息科技有限公司

Carbide-base ceramic abrasive paste as well as preparation method and application method thereof

The invention discloses a carbide-base ceramic abrasive paste as well as a preparation method, belongs to the field of cutter polishing and aims to provide a cutter abrasive paste which is rapid in polishing speed, smooth in polishing surface, good in dispersibility and easy to clean. According to the technical scheme, the abrasive paste comprises the following components in parts by mass: 60-70 parts of carbide-base ceramic powder, 10-15 parts of a dispersant, 5-10 parts of a filler, 20-30 parts of a nonionic surfactant, 10-20 parts of a lubricant and 1-5 parts of oxidized polyethylene wax micro powder, wherein the filler is one of vanadium titano-magnetite powder, vanadium titano-magnetite powder or vermiculite powder. When being used in a polishing process for cutter processing, the abrasive paste is capable of effectively improving polishing efficiency, and a cutter surface can be smooth.

Owner:CHANGZHOU JINGMEITE PRECISION TOOL CO LTD

A pvc polymer waterproof membrane

A disclosed PVC high-molecular waterproof coiled material is composed of the following raw materials in parts by weight: 10-20 parts of polyvinyl chloride, 5-10 parts of oxidized polyethylene, 5-10 parts of polyethylene, 20-40 parts of heavy calcium carbonate, 5-10 parts of stearic acid, 2-5 parts of a stabilizing agent, 3-7 parts of barium sulfate, 15-30 parts of industrial white oil, 0.5-2 parts of a filler, and 0.1-0.5 part of a defoaming powder. The beneficial effects comprise that the coiled material is prepared by taking PVC material as a main material and matching with multiple auxiliary materials and performing a high temperature reaction. The coiled material is good in flexibility, high in elongation percentage, resistant to corrosion and resistant to acids and alkalis, and is improved in service life.

Owner:XIAMEN LIKASAM WATERPROOF ENG

Preparation process of transparent PVC (polyvinyl chloride) cold-bending electrical conduit

The invention discloses a preparation process of a transparent PVC (polyvinyl chloride) cold-bending electrical conduit. The preparation process of the transparent PVC cold-bending electrical conduit comprises the following steps of (1) mixing PVC resin powder, a methyl tin stabilizer, polyethylene wax and stearic acid to obtain a PVC resin mixture; (2) adding the PVC resin mixture into a high-speed mixer, heating, and stirring and mixing for 23 to 27 minutes at a high speed; (3) transferring the PVC resin mixture heated to 143 to 147 DEG C into a low-speed mixer, cooling, and stirring and mixing for 14 to 16 minutes at a low speed; (4) transferring the PVC resin mixture cooled to 43 to 47 DEG C into a double-screw extruder for high-temperature extrusion, mulling and homogenization; (5) transferring the PVC resin mixture extruded from the double-screw extruder into a PVC electrical conduit extrusion die, and extruding to form a die; and (6) carrying out cooling molding on the demolded PVC resin electrical conduit extruded from the PVC electrical conduit extrusion mold under vacuum, then carrying out traction, cutting and packaging processes, and then carrying out inspection and warehousing. According to the preparation process of the transparent PVC cold-bending electrical conduit provided by the invention, the cost is low, the prepared PVC cold-bending electrical conduit can be transparent without adding a brightener and an organic toner into ingredients, and granulation is not needed.

Owner:NANYANG SENYUAN PLASTIC

Efficient solid screw cleaning agent and preparation method thereof

The invention discloses an efficient solid screw cleaning agent and a preparation method thereof. The efficient solid screw cleaning agent is prepared from ABS (acrylonitrile-butadiene-styrene) resin, PMMA (polymethyl methacrylate) resin, calcium carbonate masterbatch, a compatilizer and synthetic wax, wherein the cleaning capacity can be improved by means of the high-viscosity PMMA resin in the cleaning agent, compatibility between the ABS resin and the PMMA resin can be improved by means of the compatilizer, the abnormal phenomena of bar breakage and the like in an extruding granulation process are reduced, stabilization of production is facilitated, and the cleaning agent is discharged out of equipment by a follow-up material more easily during cleaning of the equipment; the capacity of the cleaning agent for cleaning residual substances can be improved by means of the synthetic wax; besides, inorganic powder is replaced with the calcium carbonate masterbatch, so that the phenomenon of powder floating is reduced, the production environment is improved, and harm of powder to the environment and the human body is reduced.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

A kind of composite polyethylene wax for plastics and preparation method thereof

The invention relates to a production method for composite polypropylene wax used for plastic. The composite polypropylene wax comprises polypropylene low polymers, Fischer-tropsch wax or microcrystalline wax and industrial hydrogenated oil, and has the properties that the softening point is 100 DEG C or above, and the average molecular weight ranges from 1500 to 3000. As an excellent dispersing agent, on the aspects of color master production and pigment dispersion, the composite polypropylene wax produced through the method has the advantages that effective molecular weights are concentrated, wherein the molecular weights are narrowly distributed and concentrated, and therefore the dispersion effect and the coloring force are easily improved, and relatively speaking, the addition amount can be decreased under the certain dispersion requirement; the excellent heat resistance and the excellent thermal stability are achieved; the melting point and the viscosity matching are moderate, and the shearing force is facilitated, wherein the softening point is 110 DEG C, the high viscosity is 150 CP / 140 DEG C, produced color master particles have high intermiscibility and mobility and moderate in viscosity, the shearing force is increased, and dispersity is improved.

Owner:扬州罗兰新材料有限公司

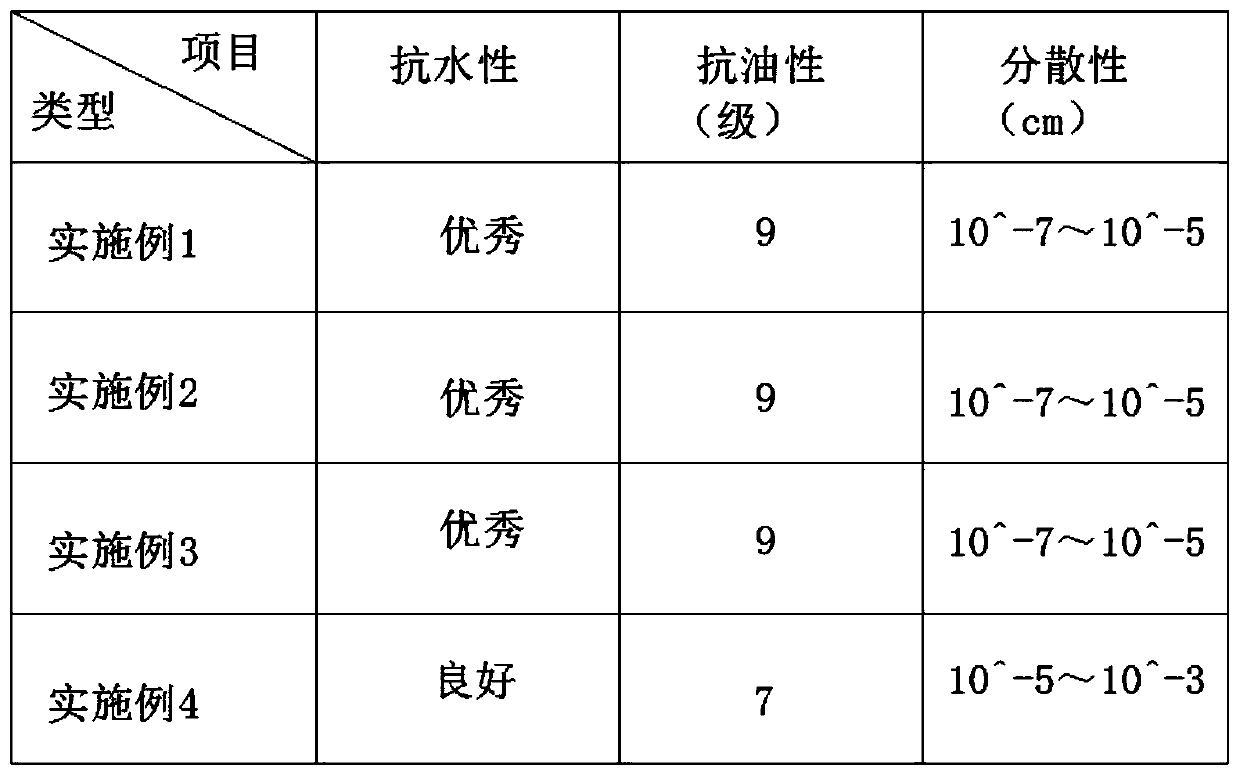

Water-resistant oil-dispersion-resistant rosin size and preparation method thereof

InactiveCN110924222AImprove water resistanceGood oil resistanceWater-repelling agents additionSurfactants additionAlkanePolymer science

The invention discloses a water-resistant oil-dispersion-resistant rosin size and a preparation method thereof. The water-resistant oil-dispersion-resistant rosin size is characterized by comprising,50-60% of rosin size, 30-40% of rosin maleic anhydride polyol ester, 20-30% of rosin, 20-30% of anhydride, 9-13% of oligomeric surfactant, 8-12% of reinforced rosin size, 8-10% of petroleum wax, 10-12% of tall oil, 8-10% of oxidized polyethylene wax, 6-8% of emulsifier, 15-25% of a tricyclic diterpene oxygen-containing compound, 10-14% of polyacrylamide dispersant, 1-2% of catalyst, 20-30% of polyethylene glycol, 30-40% of alkylene oxide, 10-12% of antioxidant and 6-9% of esterifying agent. The water-resistant oil-dispersion-resistant rosin size has the technical effects that the rosin size prepared by the formula and the preparation process has relatively high water resistance, oil resistance and dispersity.

Owner:龙游富田造纸精化有限公司

Composite material for manufacturing dry powder fire extinguisher nozzle and method for manufacturing nozzle using same

Owner:苏州厚利春塑胶工业股份有限公司

A kind of rosin sizing agent and preparation method thereof

ActiveCN113718550BKeep dryImprove water resistanceWater-repelling agents additionNon-macromolecular organic additionPolymer scienceCyclodextrin

Owner:浙江百斯特化工有限公司

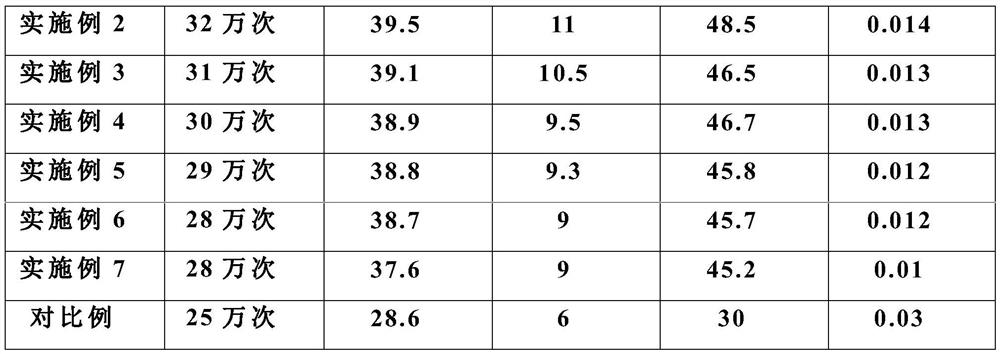

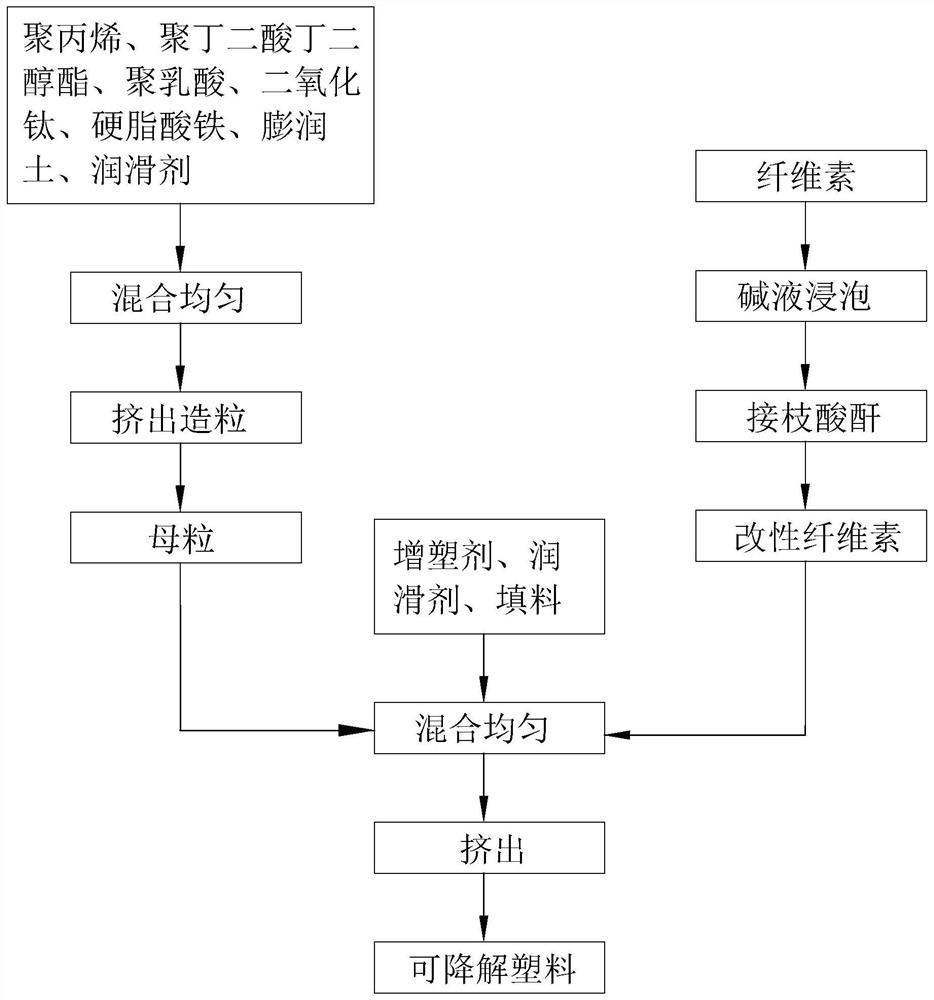

A kind of degradable plastic and preparation method thereof

The invention relates to a degradable plastic and a preparation method thereof, belonging to the technical field of plastics, comprising the following raw materials in terms of parts by mass: 40-50 parts of modified cellulose, 10-15 parts of polypropylene, polybutylene succinate 8-12 parts of glycol ester, 12-15 parts of polylactic acid, 5-8 parts of plasticizer, 1-3 parts of lubricant, 4-7 parts of filler, 2-5 parts of titanium dioxide, 1-3 parts of iron stearate And 3 to 5 parts of bentonite. The invention modifies the cellulose so that the interfacial compatibility between the modified cellulose and other raw materials is good, so that the prepared degradable plastic has excellent mechanical properties and uniform properties everywhere.

Owner:宝兴精密(深圳)有限公司

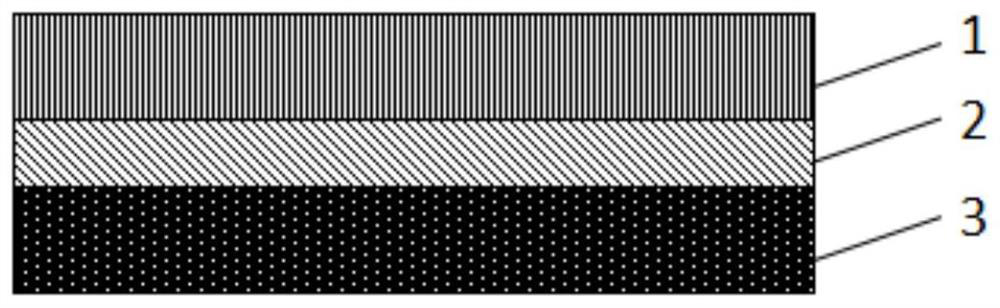

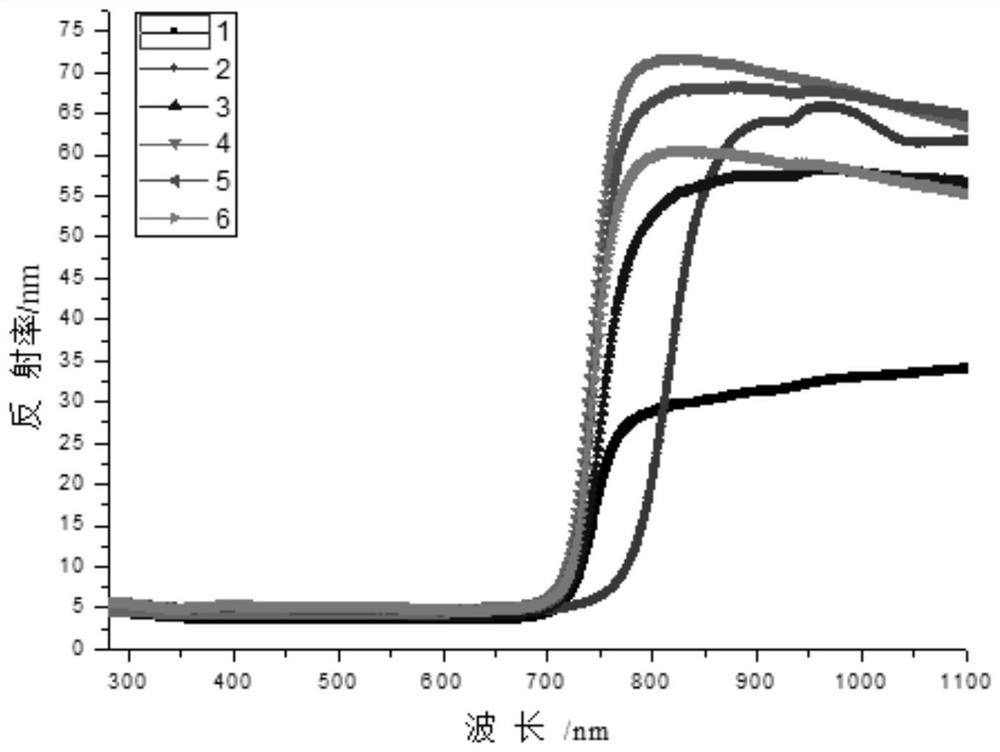

A kind of high reflectivity black solar battery back plate and preparation method thereof

ActiveCN111682083BHigh reflectivity effectImprove absorption conversion efficiencyPhotovoltaic energy generationSemiconductor devicesPolyolefinEngineering

The invention relates to the technical field of solar cells, in particular to a high-reflectivity black solar cell backplane and a preparation method thereof. The solar cell backplane comprises a weather-resistant layer, an adhesive layer and a black reflective layer sequentially arranged from top to bottom. The black reflective layer includes the following raw materials in parts by weight: 20-90 parts of a first polyolefin resin, 15-90 parts of a first adhesive resin, and 10-25 parts of a black functional masterbatch. The backplane of the present invention can have a reflectivity of 25-80% for near-infrared light of 700-1100 nanometers, and can reflect the near-infrared light to crystalline silicon, thereby improving the solar cell backplane's absorption and conversion efficiency of the solar spectrum. In addition, the The preparation method is simple and efficient, the operation and control are convenient, and the quality of the produced product is high, which is favorable for industrialized production, and at the same time, the absorption and conversion efficiency of the prepared solar cell back sheet to the solar spectrum is improved.

Owner:SUZHOU MINGGUAN NEW MATERIAL TECH CO LTD

A kind of thin film for solar battery backplane and preparation method thereof

ActiveCN104112785BGood weather resistanceImprove barrier propertiesFinal product manufacturePhotovoltaic energy generationBlow moldingPolyolefin

The invention relates to the technical field of solar cell back plate, and particularly to a film used for a synergistic type solar cell back plate and a preparation method thereof. The film is 15-150 microns in thickness and comprises the following raw materials in parts by weight: 10-90 parts by weight of polyolefin resin, 10-90 parts by weight of adhesive resin and 5-25 parts by weight of functional master batch; the preparation method of the film comprises the following steps of: mixing a polyolefin resin powder material, an adhesive resin powder material and a functional assistant, and extruding the mixture at 100-250 DEG C by adopting a screw extruder to obtain the functional master batch; mixing the prepared functional master batch with the polyolefin resin and the adhesive resin, and preparing the film at 100-250 DEG C by adopting an extrusion tape casting mode or a blow molding mode. The film disclosed by the invention can absorb ultraviolet lights of 10-400 nm, can convert and utilize optical waves which an existing battery piece cannot convert, can widen a solar spectrum absorption and conversion range, and enables a prepared solar cell component to have high photoelectric conversion efficiency.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com