Preparation method of high density polyethylene resin special for abnormal-shape bottles

A high-density polyethylene and polyethylene special-shaped technology, which is applied in the field of high-end food and medicine packaging bottles, can solve the problems of increasing labor intensity of workers, high prices of raw materials in the same period, and easy deformation of bottles, so as to improve the appearance of finished products and improve production and processing. The effect of high efficiency and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The compound antioxidant consists of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, tris(2,4-di-tert-butylphenyl) phosphite, thio Dilauryl dipropionate is prepared according to the ratio of 60 / 24 / 16 (mass percentage).

[0031] On the HDPE device, a special processing aid compounded by antioxidant, lubricant calcium stearate, fluoroelastomer and oxidized polyethylene wax according to 10 / 50 / 20 / 20 (mass percentage) is added to the base resin, The addition amount is 0.6% (mass percentage), and it is melted, extruded and granulated in an extruder to directly prepare high-density polyethylene special-shaped bottle resin.

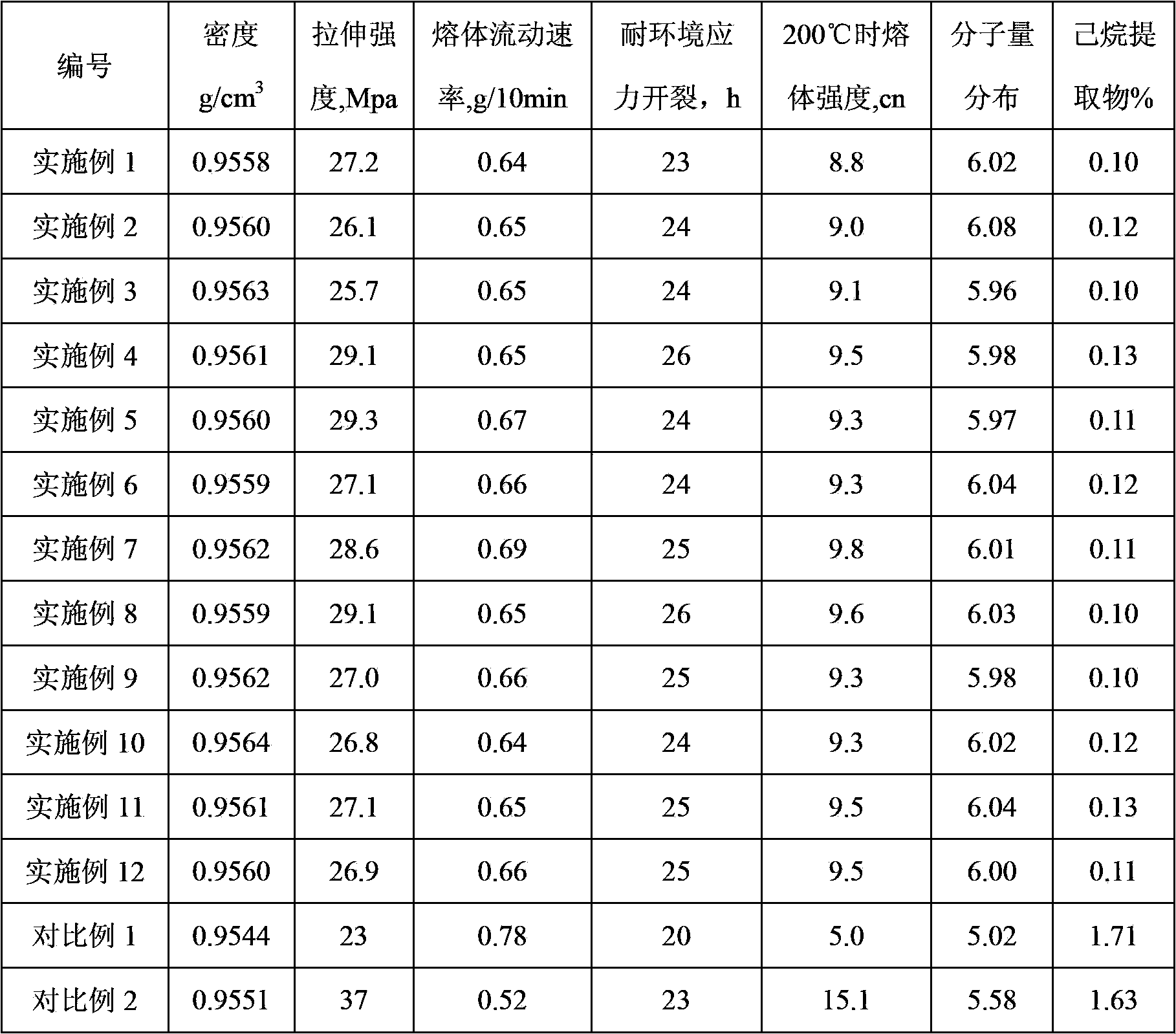

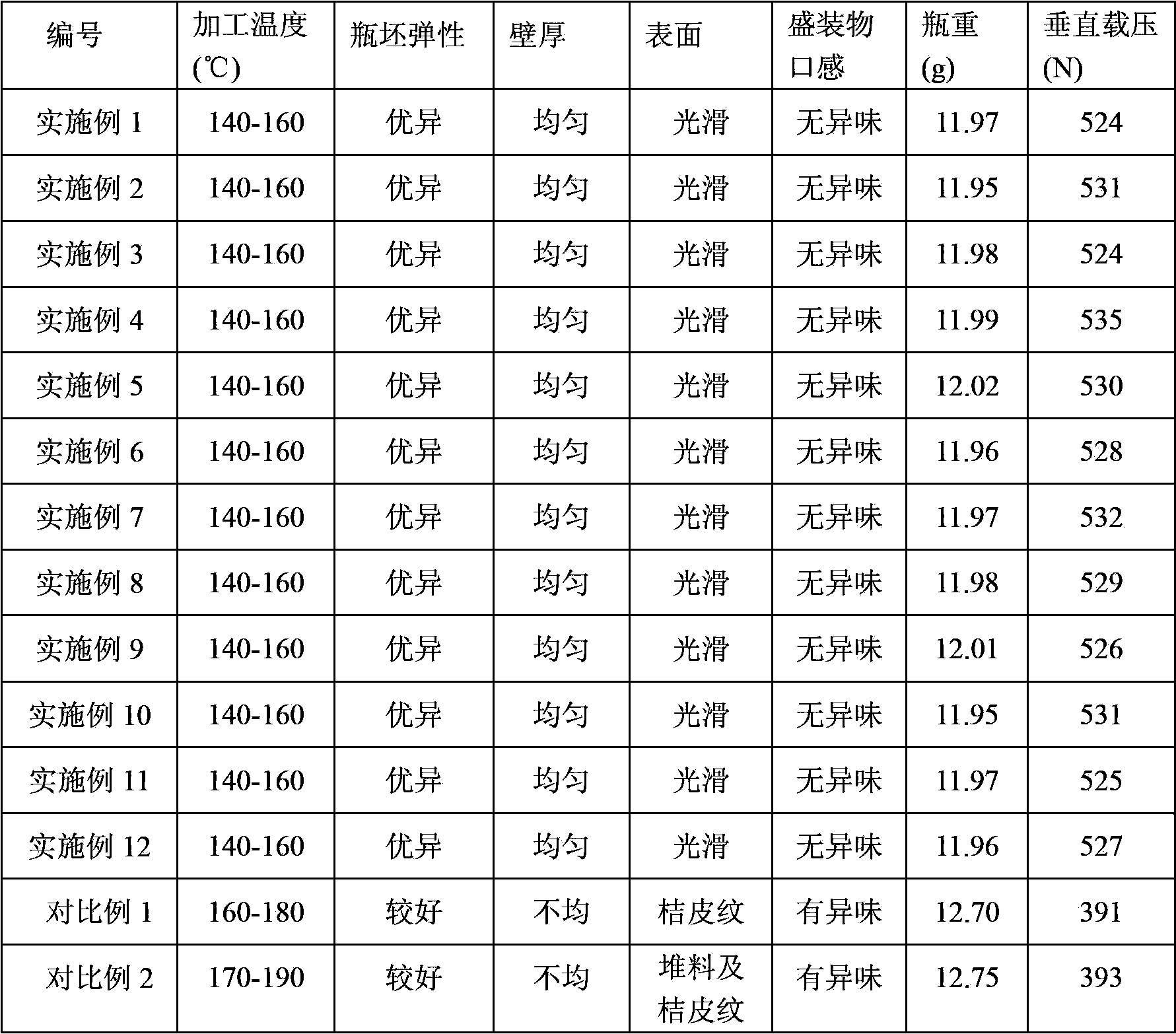

[0032] The physical property analysis and test of the obtained special resin are shown in Table 1, and the post-processing results are shown in Table 2.

Embodiment 2

[0034] The composite antioxidant consists of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, pentaerythritol bisphosphite di(octadecanol) ester, dithiodipropionate Lauryl ester is prepared according to the ratio of 60 / 24 / 16 (mass percentage).

[0035] On the HDPE device, a special composite processing compounded by antioxidant, lubricant calcium stearate, fluoroelastomer and oxidized polyethylene wax according to the ratio of 10 / 50 / 20 / 20 (mass percentage) is added to the base resin Auxiliary, added in an amount of 0.6% (mass percentage), melted and extruded in an extruder to granulate, and directly prepared high-density polyethylene special-shaped bottle resin.

[0036] The physical property analysis and test of the obtained special resin are shown in Table 1, and the post-processing results are shown in Table 2.

Embodiment 3

[0038] The composite antioxidant is composed of β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate n-octadecanoate, tris(2,4-di-tert-butylphenyl) phosphite, thio Dilauryl dipropionate is prepared according to the ratio of 60 / 24 / 16 (mass percentage).

[0039] On the HDPE device, a special composite processing compounded by antioxidant, lubricant calcium stearate, fluoroelastomer and oxidized polyethylene wax according to the ratio of 10 / 50 / 20 / 20 (mass percentage) is added to the base resin Auxiliary, added in an amount of 0.6% (mass percentage), melted and extruded in an extruder to granulate, and directly prepared high-density polyethylene special-shaped bottle resin.

[0040] The physical property analysis and test of the obtained special resin are shown in Table 1, and the post-processing results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com