A kind of degradable plastic and preparation method thereof

A technology for degrading plastics and raw materials, applied in the field of plastics, can solve the problems of limited plastic products, poor interface compatibility, uneven mechanical properties of degradable plastics, etc., and achieve excellent external lubricity, good compatibility, and small friction coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

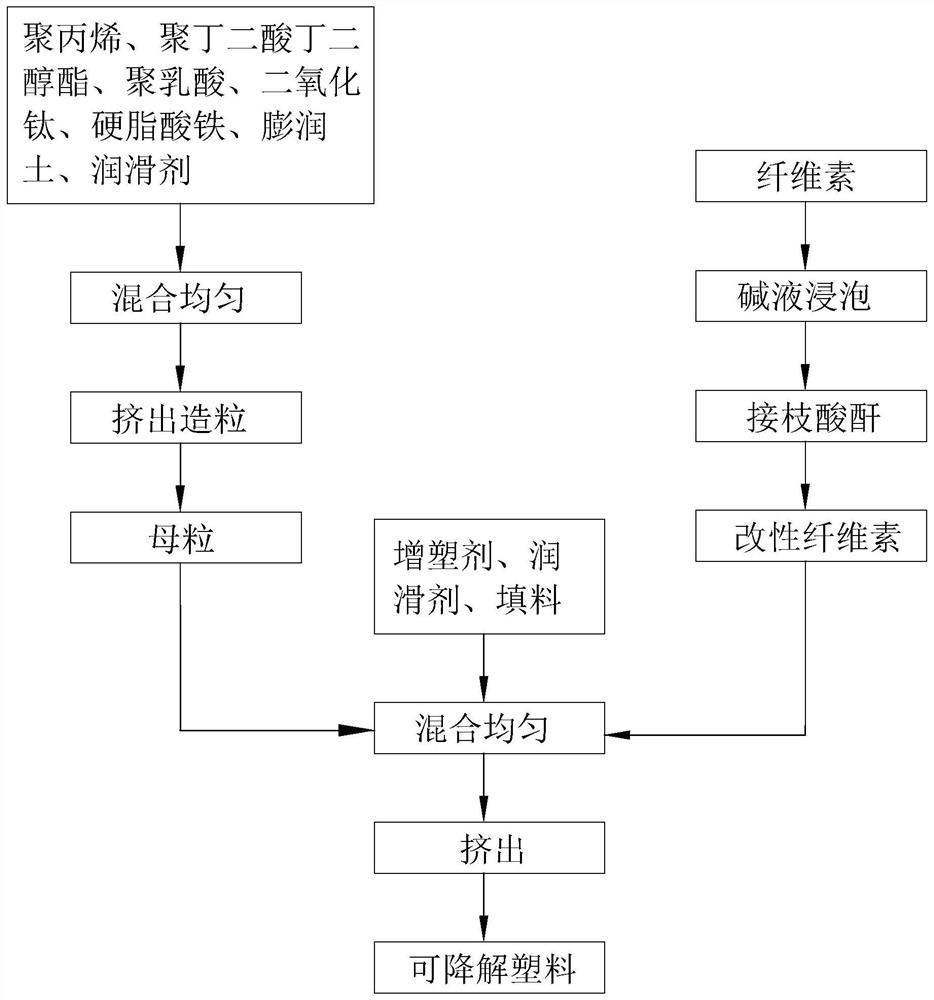

Method used

Image

Examples

Embodiment 1

[0032] Table 1 is each raw material and weight thereof of a kind of degradable plastic of embodiment 1

[0033] components mass (kg) components mass (kg) Modified Cellulose 40 Oxidized polyethylene wax 1 Polypropylene 15 Ground calcium carbonate 4 polybutylene succinate 8 Titanium dioxide 2 polylactic acid 12 Iron stearate 1 glycerin 5 Bentonite 5

[0034] Wherein the preparation method of modified cellulose is: 1) soak 100kg cellulose in 2000kg lye for 5h, lye is the mixing of 1600kg mass fraction of 5wt% sodium hydroxide aqueous solution and 400kg mass fraction of 2wt% hydrogen peroxide solution solution, the temperature of the alkali solution is 60°C, and the soaking process is continuously stirred; 2) After soaking, filter and wash 4 times until the filtrate is neutral, and the filter cake is dried and ground; 3) After melting 300kg of glutaric anhydride, add 1kg Concentrated sulfuric acid with a mass fraction ...

Embodiment 2

[0039] Table 2 is each raw material and weight thereof of a kind of degradable plastic of embodiment 2

[0040] components mass (kg) components mass (kg) Modified Cellulose 45 Silicone powder 1 Polypropylene 10 Ground calcium carbonate 5 polybutylene succinate 10 Titanium dioxide 3 polylactic acid 15 Iron stearate 2 Dibutyl phthalate 5 Bentonite 3

[0041] Wherein the preparation method of modified cellulose is: 1) soak 100kg cellulose in 2200kg lye for 3h, lye is the mixing of 1760kg mass fraction of 5wt% sodium hydroxide aqueous solution and 440kg mass fraction of 2wt% hydrogen peroxide solution solution, the temperature of the lye is 60°C, and the soaking process is continuously stirred; 2) After soaking, filter and wash 5 times until the filtrate is neutral, and the filter cake is dried and ground; 3) According to the number of parts by mass, 400kg After the acid anhydride is melted, add 2 kg of concentrated ...

Embodiment 3

[0046] Table 3 is each raw material and weight thereof of a kind of degradable plastic of embodiment 3

[0047] components mass (kg) components mass (kg) Modified Cellulose 50 Stearamide 1 Polypropylene 12 Ground calcium carbonate 6 polybutylene succinate 12 Titanium dioxide 4 polylactic acid 13 Iron stearate 3 glycerin 5 Bentonite 4 Dibutyl phthalate 3

[0048] Wherein the preparation method of modified cellulose is: 1) soak 100kg cellulose in 2400kg lye for 4h, lye is the mixing of 1920kg mass fraction of 5wt% sodium hydroxide aqueous solution and 480kg mass fraction of 2wt% hydrogen peroxide solution solution, the temperature of the lye is 40°C, and the soaking process is continuously stirred; 2) After soaking, filter and wash 4 times until the filtrate is neutral, and the filter cake is dried and ground; 3) According to the number of parts by mass, 350kg After the acid anhydride is melted, add 1.5kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com