Method and equipment for producing gas by coke gasification

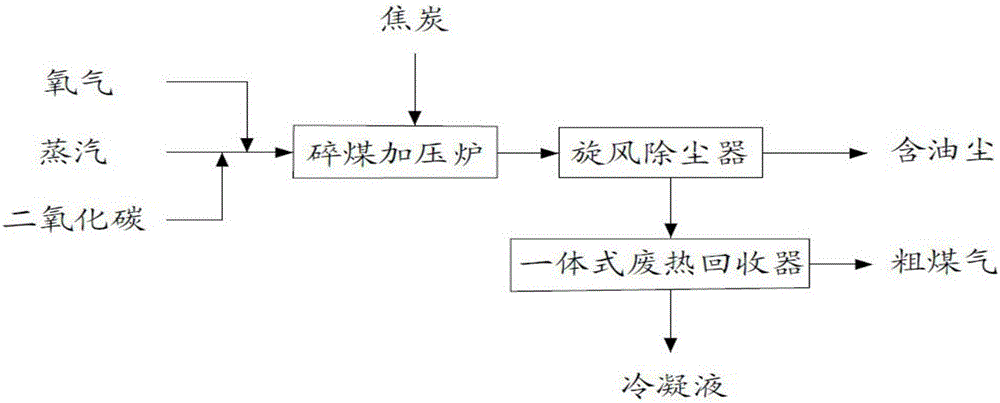

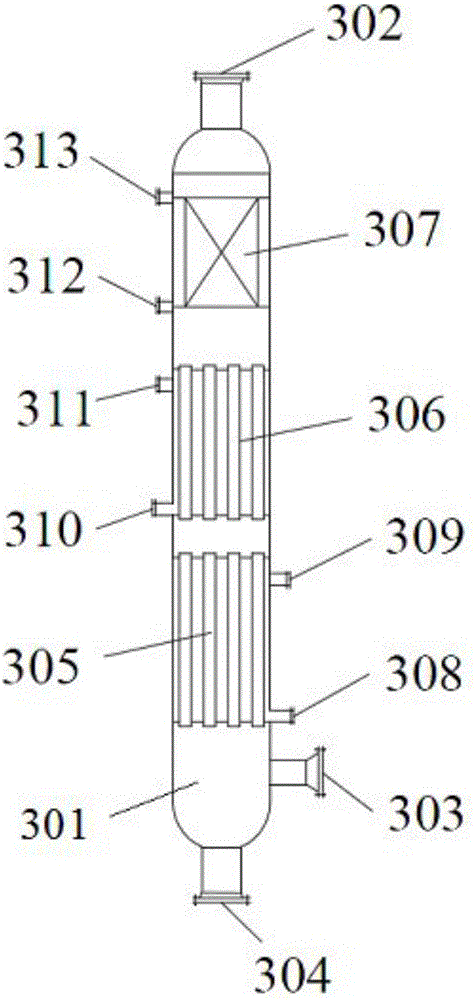

A coke and gas technology, applied in the field of coke gasification to produce gas, can solve the problems of high temperature of coke gasification gas, failure of waste heat recovery and utilization, and increase of the proportion of inferior coal, so as to achieve high heat recovery efficiency and facilitate the classification of waste heat Effect of recycling and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Crushed coal pressurized gasifier means that the height of the Lurgi furnace extends to 2.9 meters, and the Bosman sleeve adopts a water jacket structure.

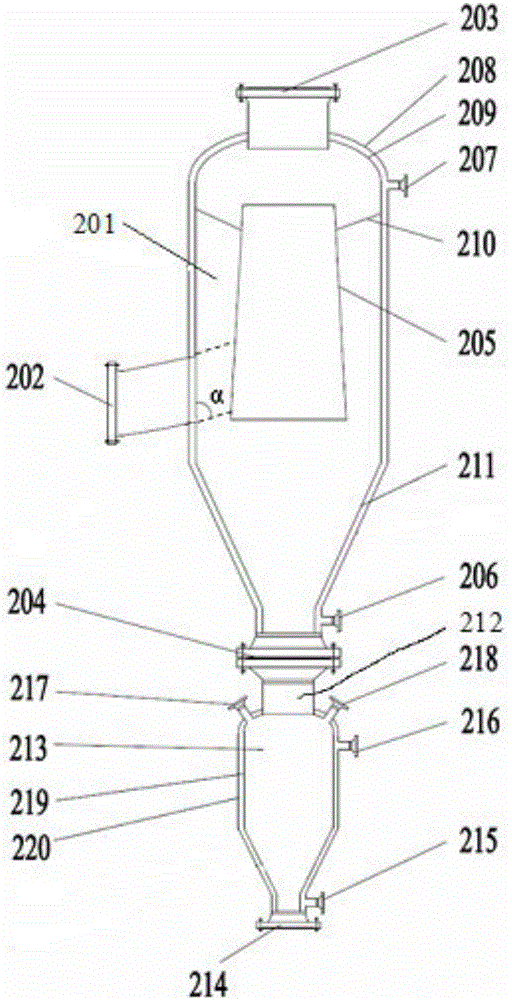

[0041] The dust removal cyclone separator device includes a cyclone dust collector 201 and an ash tank 213. The cyclone dust collector 1 includes an outer cylinder body 211 and an inner cylinder body 205. The upper part of the outer cylinder body 211 is a straight cylinder, the lower part is an inverted cone, and the outer cylinder body 211 is composed of the outer wall 208 of the outer cylinder and the inner wall 209 of the outer cylinder, and forms a jacket structure. The inner cylinder 205 is fixed on the inner wall 209 of the outer cylinder through a stretching member 210. The crude gas inlet 202 containing oil and dust passes through the outer cylinder 211 and The lower part of the inner cylinder 205 is connected, the crude gas outlet 203 is located at the top of the outer cylinder 211, the upper part of the out...

Embodiment 2

[0059] The crushed coal pressurized gasifier is a 1.1-meter-high extension of the Saiding furnace, and the Bosman sleeve adopts a water jacket structure.

[0060] The angle α formed between the oily and dusty crude gas inlet 202 and the inner wall 209 of the outer cylinder is 76 degrees. The wall temperature of the inner wall 209 of the outer cylinder and the inner wall 219 of the ash tank is 273°C.

[0061] The cyclone dust collector 201 of the present invention is based on the diameter of 1 m of the inner wall 209 of the outer cylinder, and other structural relative parameters are shown in Table 3.

[0062] Table 3 Design structural parameters of cyclone dust collector

[0063]

[0064]

[0065] (1) Coke is used as raw material to generate crude gas containing oil and dust with a pressure of 7.8MPa and a temperature of 640°C through crushed coal pressurized gasification;

[0066] (2) The crude gas containing oil and dust enters the cyclone separator 201 in the dust r...

Embodiment 3

[0070] The crushed coal pressurized gasifier is a 2.5-meter-high extension of the Saiding furnace, and the Bosman sleeve adopts a water jacket structure.

[0071] The angle α formed between the oily and dusty crude gas inlet 202 and the inner wall 209 of the outer cylinder is 82 degrees. The wall temperature of the inner wall 209 of the outer cylinder and the inner wall 219 of the ash tank is 225°C.

[0072] The cyclone dust collector 201 of the present invention is based on the diameter of 1 m of the inner wall 209 of the outer cylinder, and other structural relative parameters are shown in Table 4.

[0073] Table 4 Design structural parameters of cyclone dust collector

[0074] serial number

structure name

Structural relative parameters (unit m)

1

209 diameter of the inner wall of the outer cylinder

1.0

2

Oil and dust crude gas inlet 202 position (measured from the bottom of the straight cylinder of the outer cylinder)

0.40

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com