Preparation process of pickles

A preparation process, technology of pickled vegetables, applied to bacteria used in food preparation, functions of food ingredients, alcohol-containing food ingredients, etc., can solve the problem of single flavor of the product, achieve high nutritional value, stabilize blood pressure, and speed up production the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare the raw materials according to the following formula 1~8

[0032] Recipe 1: 35g mustard tuber, 24g radish, 11g cowpea.

[0033] Recipe 2: 48g cowpea, 23g mustard tuber.

[0034] Recipe 3: 30g mustard tuber, 20g radish, 20g cowpea.

[0035] Recipe 4: 25g mustard tuber, 25g yellow flower, 12g radish, 10g cowpea.

[0036] Recipe 5: 36g mustard tuber, 35g radish.

[0037] Recipe 6: 62g radish.

[0038] Recipe 7: 67g cowpea.

[0039] Recipe 8: 25g mustard tuber, 25g yellow flower, 11g radish, 10g cowpea.

Embodiment 2

[0041] Prepare auxiliary materials according to the following formula A~H

[0042] Formula A: Soybean 5g, Rapeseed Oil 5g, Edible Salt 3g, Chili 5g, Ginger 2g, Garlic 1.5g, Spices 2g (Star Anise 0.4g, Kaempferi 0.4g, Cumin 0.3g, Cinnamon Bark 0.3g, Grass Fruit 0.3g , Clove 0.3g), white wine 1g, white sugar 1g, yeast extract 1g, sodium glutamate 1g, lactic acid 0.5g, citric acid 0.5g, acesulfame K 0.01g, capsicum 0.2g, flavored nucleotide Disodium 0.585g, lemon yellow 0.005g, food flavor 0.2g, sodium D-isoascorbate 0.5g.

[0043] Recipe B: Rapeseed oil 6g, edible salt 3g, chili 6g, ginger 2g, garlic 1.5g, spices 2g (star anise 0.4g, kaempferi 0.4g, cumin 0.3g, cinnamon 0.3g, grass fruit 0.3g, clove 0.3 g), 1g white wine, 1g white sugar, 2g yeast extract, 2g sodium glutamate, 0.5g lactic acid, 0.5g citric acid, 0.01g acesulfame K, 0.1g capsicum, 0.885 disodium nucleotides g. Lemon yellow 0.005g, D-sodium erythorbate 0.5g.

[0044] Formula C: Soybean 6g, rapeseed oil 7.5g, edible sal...

Embodiment 2~18

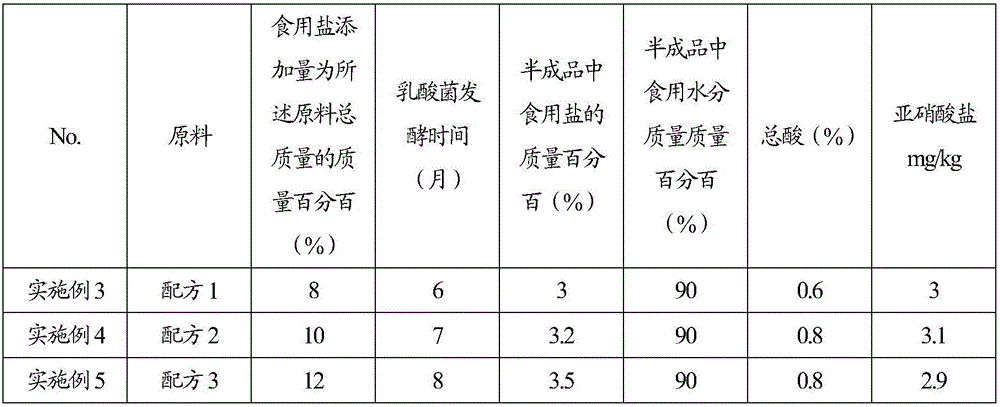

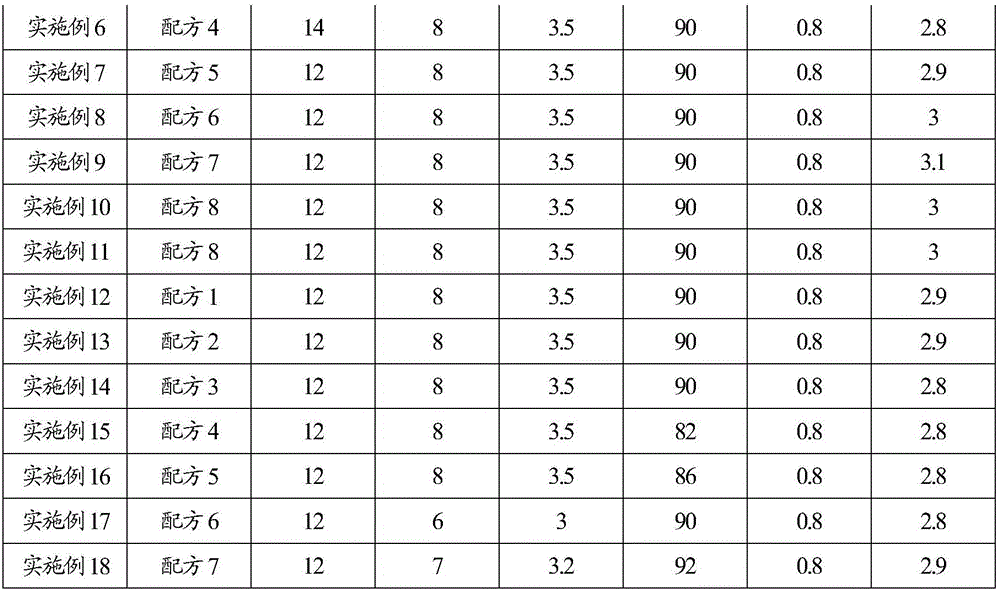

[0051] Vegetable salting: According to Table 1, select raw material formulas 1-8, add edible salt sand, press and seal, and add 0.01-0.02% lactic acid bacteria natural fermentation of the raw material.

[0052] Cleaning: Clean with tap water, remove foreign objects, trim old tendons and old skin.

[0053] Shaping: Cut raw materials into shreds, slices, dices, etc. according to the process.

[0054] Desalination: Desalination on the desalination machine to control the edible salt content.

[0055] Dehydration: Dehydrate on the press to control the moisture content to obtain semi-finished products.

[0056] The first test: In the semi-finished product, the quality percentage of edible salt calculated as NaCl; the quality percentage of water; the total acid content calculated as lactic acid; NaNO 2 Calculated nitrous acid content. The test results are shown in Table 1.

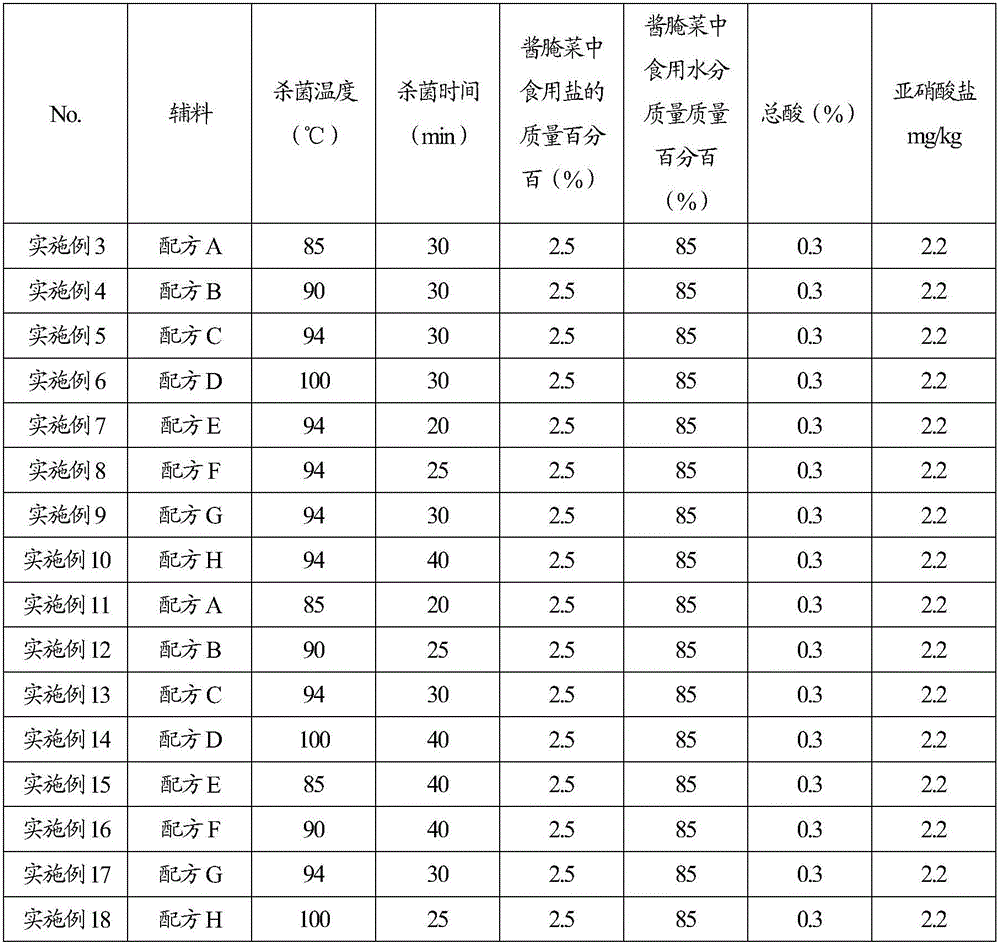

[0057] Seasoning: According to the testing data of semi-finished products, use formula A to H to season according to Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com