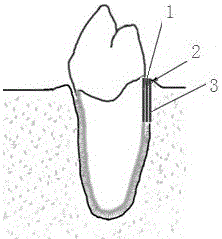

Biomimetic layered stent for periodontal tissue defect repair and preparation method thereof

A periodontal tissue and bionic layer technology, applied in the field of bionics, can solve the problems of chronic tissue inflammation, inability to fully produce the three-layer structure of periodontal tissue, etc., to ensure the effect of periodontal repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Synthesis of CH-PCL copolymer: 6g of chitosan with a degree of deacetylation of 100% and 18g of phthalic anhydride were heated to 130°C in dry dimethylformamide, and reacted for 5 -7 hours, the mixture turned into a clear yellow liquid; this moment to obtain the intermediate product A (phthalylated chitosan), then the above-mentioned mixture containing A and 21g of caprolactone in N 2 Protection, stirring constantly under the condition of 100 ℃, reacting for 20 hours, at this time, the intermediate product B (phthalylated chitosan-g-polycaprolactone) is obtained, and then the reactant is placed in a Soxhlet extractor Extract with acetone for 24 hours to remove the homopolymer in the reaction; finally take 30g of the extracted B product and dissolve it in 600ml of dimethylformamide, 100°C, N 2 Incubate for 2 hours under protective conditions, cool to room temperature and allow it to precipitate naturally, collect the precipitate, rinse with double distilled water and ...

Embodiment 2

[0073] 1. Synthesis of CH-PCL copolymer: 20g of chitosan with 100% degree of deacetylation and 60g of phthalic anhydride were heated to 130°C in dry dimethylformamide, and reacted for 5 -7 hours, the mixture turned into a clear yellow liquid; at this moment, the intermediate product A (phthalylated chitosan) was obtained, and then the above-mentioned mixture containing A and the caprolactone of 72g were protected in N , at 100C Stir constantly under condition, react 20 hours, obtain intermediate product B (phthalylated chitosan-g-polycaprolactone) this moment, then reactant is placed in Soxhlet extractor with acetone extraction 24 hours to remove homopolymers in the reaction; finally take 42g of the extracted B product and dissolve it in 840ml of dimethylformamide, incubate at 100°C for 2 hours under N2 protection conditions, cool to room temperature and allow it to precipitate naturally, and collect the precipitate The substance was rinsed with double distilled water and etha...

Embodiment 3

[0102]1. Synthesis of CH-PCL copolymer: 14g of chitosan with a degree of deacetylation of 100% and 42g of phthalic anhydride were heated to 130°C in dry dimethylformamide, and reacted under conventional experimental conditions for 5 -7 hours, the mixture turned into a clear yellow liquid; at this time, the intermediate product A (phthalylated chitosan) was obtained, and then the above-mentioned mixture containing A and 21g of caprolactone were protected under N2 at 100°C Stir constantly under the condition, react 20 hours, obtain intermediate product B (phthalylated chitosan-g-polycaprolactone) at this moment, then reactant is placed in Soxhlet extractor and extracted with acetone 24 hours to remove the homopolymer in the reaction; finally take 36g of the extracted B product and dissolve it in 720ml of dimethylformamide, incubate at 100°C for 2 hours under N2 protection conditions, cool to room temperature and allow it to precipitate naturally, collect The precipitate was rins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com