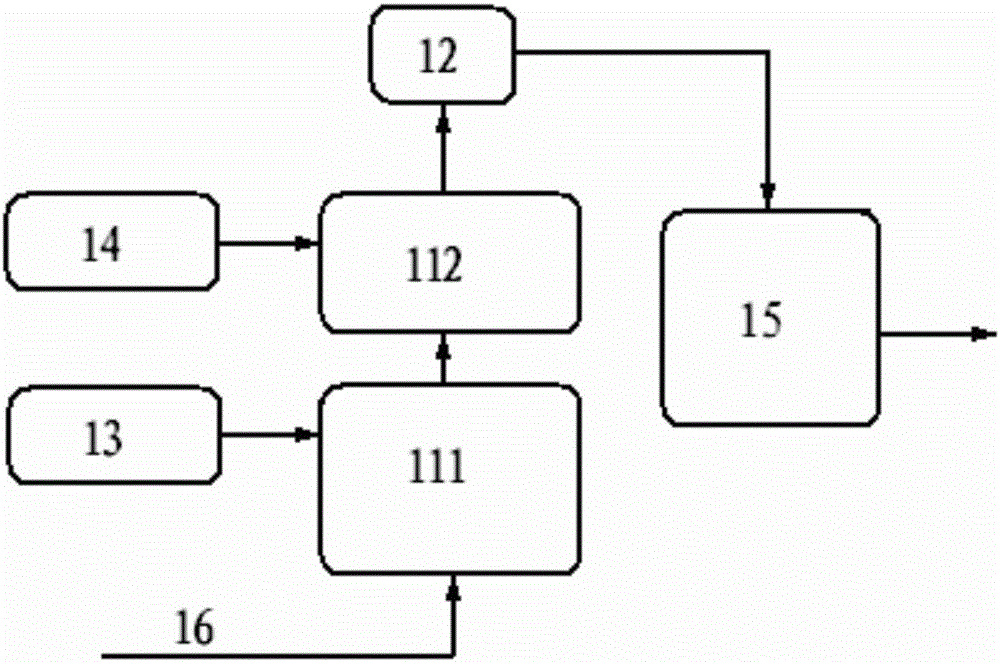

Method and system for treating foul gas

A technology of malodorous gas and treatment method, which is applied in the directions of gas treatment, separation method, chemical instrument and method, etc., can solve the problems of limited chemical oxidant oxidation-reduction potential, unsatisfactory purification effect, difficult reaction, etc., to improve the scope of application , Enhance purification efficiency, strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

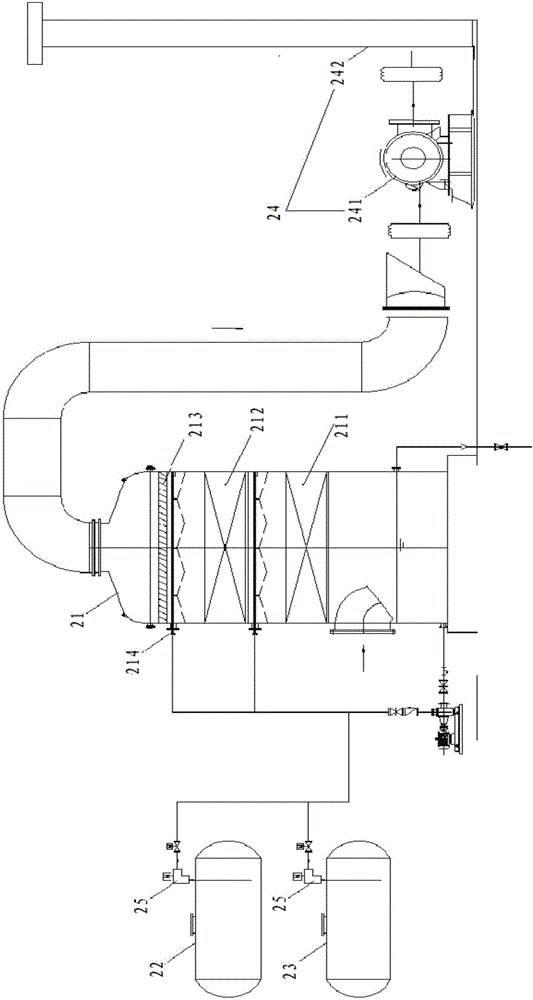

Embodiment 1

[0075] 500 tons of domestic waste incineration treatment plant is processed a day, and the amount of odorous exhaust gas in the waste storage pit is 30,000m in emergency situations 3 / h, the odor concentration is 10000, the phase transfer accelerator used is polyether, the molecular weight is 600, and the concentration of its aqueous solution is 1wt%; the oxidant is hydrogen peroxide aqueous solution, and the concentration of use is 3wt%. The oxidation tower adopts the method of entering from the bottom and exiting from the top, with a tower diameter of 4m. It is equipped with two-stage contact reaction units, which are the phase transfer treatment unit and the oxidation treatment unit (the phase transfer treatment unit is located at the bottom, the oxidation treatment unit is located at the top, and the gas to be treated enters first. phase transfer treatment unit, and then into the oxidation treatment unit), the height of each stage is 800mm, the spray unit is composed of noz...

Embodiment 2

[0079] The incineration plant handles 600 tons of domestic waste per day, and the amount of odorous exhaust gas in the waste storage pit is 35,000m in emergency situations 3 / h, the odor concentration is 12000, the phase transfer accelerator used is tetrabutylphosphonium bromide, the concentration of its aqueous solution is 5wt%; the oxidant is sodium hypochlorite aqueous solution, and the concentration of use is 1wt%. The oxidation tower adopts the method of entering from the bottom and exiting from the top, with a tower diameter of 4m. It is equipped with two-stage contact reaction units, which are the phase transfer treatment unit and the oxidation treatment unit (the phase transfer treatment unit is located at the bottom, the oxidation treatment unit is located at the top, and the gas to be treated enters first. phase transfer treatment unit, and then into the oxidation treatment unit), the height of each stage is 600mm, the spray unit is composed of nozzles and nozzles, the ...

Embodiment 3

[0083] The incineration plant handles 800 tons of domestic waste per day, and the amount of odorous exhaust gas in the waste storage pit is 25,000m in emergency situations 3 / h, the odor concentration is 11000, the phase transfer accelerator used is polyether, the molecular weight is 400, and the concentration of its aqueous solution is 0.2wt%; the oxidant is hydrogen peroxide aqueous solution, and the concentration of use is 10wt%. The oxidation tower adopts the method of entering from the bottom and exiting from the top, with a tower diameter of 4m. It is equipped with two-stage contact reaction units, which are the phase transfer treatment unit and the oxidation treatment unit (the phase transfer treatment unit is located at the bottom, the oxidation treatment unit is located at the top, and the gas to be treated enters first. phase transfer treatment unit, and then into the oxidation treatment unit), the height of each stage is 1000mm, the spray unit is composed of nozzles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Ball diameter | aaaaa | aaaaa |

| Ball diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com