Manufacturing method for GTAW double-synchronization filler rod additive of non-closed thin-wall structural member

A technology of thin-walled structural parts and additive manufacturing, which is applied in the field of additive manufacturing, can solve the problems that the quality control of non-closed path structural parts is not yet feasible, the forming process cannot continue, and the size difference of formed components increases. Effects of improving build-up forming quality, shortening additive manufacturing cycle, and increasing cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

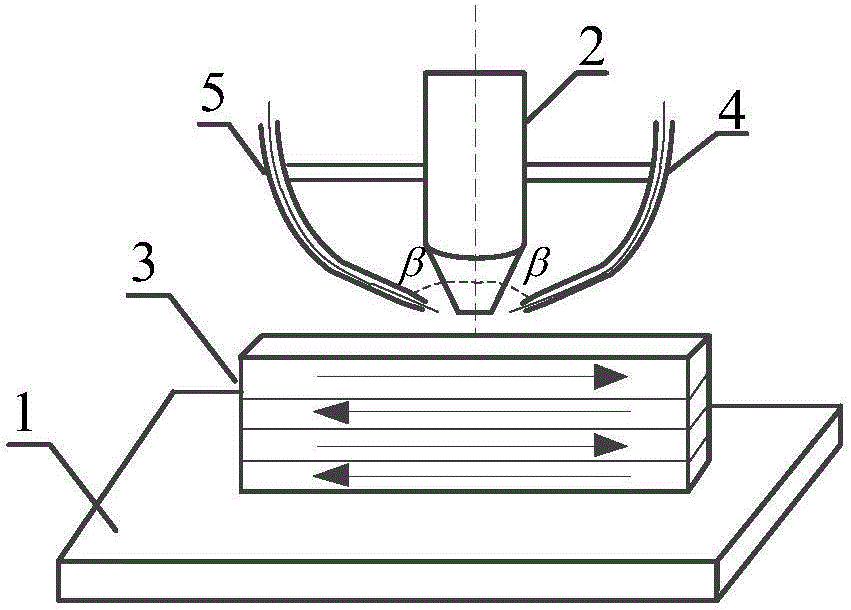

[0032] combine figure 1 Describe this embodiment, a non-closed thin-walled structural part GTAW double synchronous wire-filling additive manufacturing method described in this embodiment, the non-closed thin-walled structural part is a multi-layer single-channel structural part that is not connected from end to end, Described method is realized through the following steps:

[0033] Step 1: Install the copper alloy wire guide tubes 5 and 4 symmetrically on the left and right sides of the GTAW welding torch 2 respectively, and the angle β between the wire guide tube and the welding torch is 35°.

[0034]Step 2: Grinding the surface of the substrate 1 before stacking, and then using acetone to remove oil stains on the surface of the substrate 1, and fixing the cleaned substrate 1 on a fixture for additive manufacturing. The GTAW welding torch 2 is moved above the substrate so that the tip of the tungsten pole is 2mm away from the substrate surface, and the starting point of the ...

Embodiment 2

[0040] combine figure 1 Describe this embodiment, a non-closed thin-walled structural part GTAW double-filling wire additive manufacturing method described in this embodiment, the non-closed thin-walled structural part is a multi-layer single-channel structural part that is not connected from end to end, so Said method is realized through the following steps:

[0041] Step 1: install the copper alloy wire guide tubes 5 and 4 symmetrically on the left and right sides of the GTAW welding torch 2 respectively, and the angle β between the guide wire tube and the welding torch is 65°.

[0042] Step 2: Grinding the surface of the substrate 1 before stacking, and then using acetone to remove oil stains on the surface of the substrate 1, and fixing the cleaned substrate 1 on a fixture for additive manufacturing. The GTAW welding torch 2 is moved above the substrate so that the tip of the tungsten pole is 6mm away from the substrate surface, and the starting point of the accumulation ...

Embodiment 3

[0048] combine figure 1 Describe this embodiment, a non-closed thin-walled structural part GTAW double-filling wire additive manufacturing method described in this embodiment, the non-closed thin-walled structural part is a multi-layer single-channel structural part that is not connected from end to end, so Said method is realized through the following steps:

[0049] Step 1: install the copper alloy wire guide tubes 5 and 4 symmetrically on the left and right sides of the GTAW welding torch 2 respectively, and the angle β between the wire guide tube and the welding torch is 50°.

[0050] Step 2: Grinding the surface of the substrate 1 before stacking, and then using acetone to remove oil stains on the surface of the substrate 1, and fixing the cleaned substrate 1 on a fixture for additive manufacturing. The GTAW welding torch 2 is moved above the substrate so that the tip of the tungsten pole is 6mm away from the substrate surface, and the starting point of the accumulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com