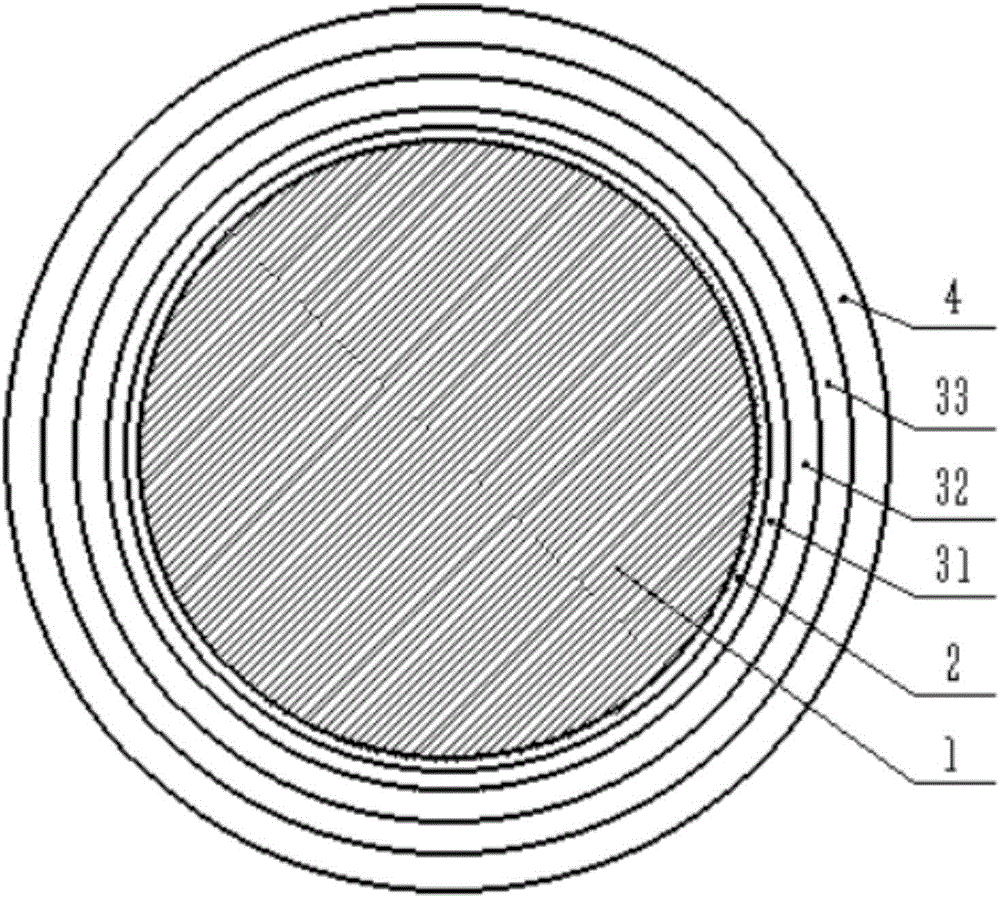

Road wheel and press-casting process thereof

A road wheel and process technology, which is applied to other household appliances, epoxy resin glue, tires, etc., can solve the problems of uneven vulcanization, non-compact interior, and low bonding strength of the metal wheel body, so as to avoid complicated processes, Improve the bonding strength and solve the effect of poor bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Step 1. Preparation of rubber strips: Pass the track compound rubber and vulcanizing agent on the open mill at a mass ratio of 100: (0.5-1.5), so that the track compound rubber and vulcanizing agent are mixed evenly and air bubbles are removed to obtain rubber Mixed material; then the rubber mixed material is preformed by a rubber extruder to obtain a cylindrical solid mixed rubber material, and the mixed rubber material is cut into 2000-3000mm rubber strips;

[0028] Step 2. Surface treatment of the metal wheel body: sand blast the outer surface of the metal wheel body, and then use a silane coupling agent to clean the sandblasted metal wheel body to completely remove the dust, oil and rust on the surface of the metal wheel body. Stand for 10-30min for use;

[0029] Step 3: The construction process of the adhesive layer: Apply the adhesive layer evenly on the outer surface of the metal wheel body obtained in step 2 by brushing or spraying, which specifically includes f...

Embodiment 1

[0034] A casting process, the casting process comprises the following steps:

[0035] Preparations before production:

[0036] To prepare a silane coupling agent, take the preparation of 1000g as an example, add 3g of KH-550 silane coupling agent and 2g of KH-560 silane coupling agent to 995g of acetone solvent to obtain a silane with a mass percentage concentration of 0.5wt%. Coupling agent, ready for use.

[0037]Step 1. Preparation of rubber strips: pass the track compound rubber and vulcanizing agent on the open mill at a mass ratio of 100:0.5, so that the track compound rubber and vulcanizing agent are evenly mixed and the air bubbles are removed to obtain a rubber compound; then The rubber compound is preformed by a rubber extruder to obtain a solid cylindrical compound with a plasticity of 0.35, and the compound is cut into 2000mm rubber strips;

[0038] Step 2, surface treatment of the metal wheel body: sandblasting the outer surface of the metal wheel body, and then...

Embodiment 2

[0044] A casting process, the casting process comprises the following steps:

[0045] Preparations before production:

[0046] To prepare a silane coupling agent, take the preparation of 1000g as an example, add 6g of KH-550 silane coupling agent and 4g of KH-560 silane coupling agent to 990g of acetone solvent to obtain a silane coupling agent with a mass percentage concentration of 1wt%. Joint agent, ready to use.

[0047] Step 1. Preparation of rubber strips: pass the track compound rubber and vulcanizing agent on the open mill at a mass ratio of 100:1.0, so that the track compound rubber and vulcanizing agent are evenly mixed and the air bubbles are removed to obtain a rubber compound; then The rubber compound is preformed by a rubber extruder to obtain a solid cylindrical compound with a plasticity of 0.45, and the compound is cut into 2500mm rubber strips;

[0048] Step 2, surface treatment of the metal wheel body: sandblasting the outer surface of the metal wheel body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com