Preparation method and applications of phosphorus-free scale-inhibiting and corrosion-inhibiting agent for reusing reclaimed water in power plant

A phosphorus-free corrosion and scale inhibitor technology, applied in the field of water treatment, can solve the problems of reduced scale and corrosion inhibition effect, poor scale and corrosion inhibition effect, and poor water quality conditions, and achieves excellent sterilization effect, corrosion inhibition and resistance. Improved scaling performance, good stability and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the non-phosphorus corrosion and scale inhibitor that the reclaimed water proposed by the present invention is reused in the power plant comprises the following steps:

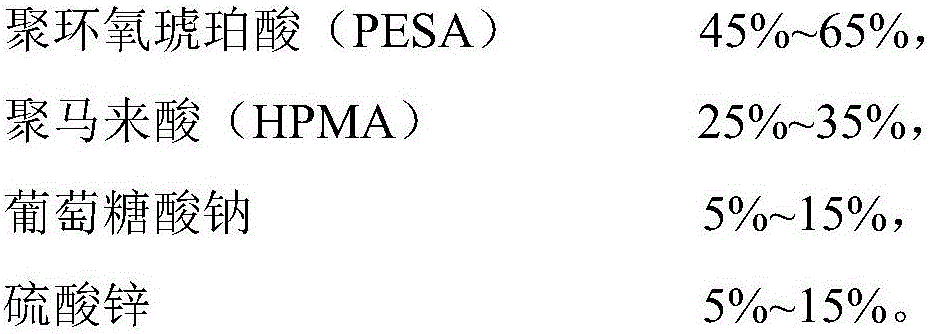

[0022] (1) Polyepoxysuccinic acid, polymaleic acid, sodium gluconate and zinc sulfate are weighed in proportion, and the mass percent is:

[0023]

[0024] The mass percent concentration of the polymaleic acid is 45% to 55%, and the free monomer of maleic acid is ≤9.0wt%;

[0025] The mass percent concentration of the polyepoxysuccinic acid is 30%-40%, and the degree of polymerization is 5-10.

[0026] (2) Mix polyepoxysuccinic acid, polymaleic acid and sodium gluconate weighed according to the above ratio, heat to 70-90°C, and keep for 1.5-2.0 hours to obtain the first solution;

[0027] (3) the zinc sulfate that weighs by above-mentioned ratio is mixed with the zinc sulfate aqueous solution that mass concentration is 10%~20%, in the first solution of above-mentioned step ...

Embodiment 1

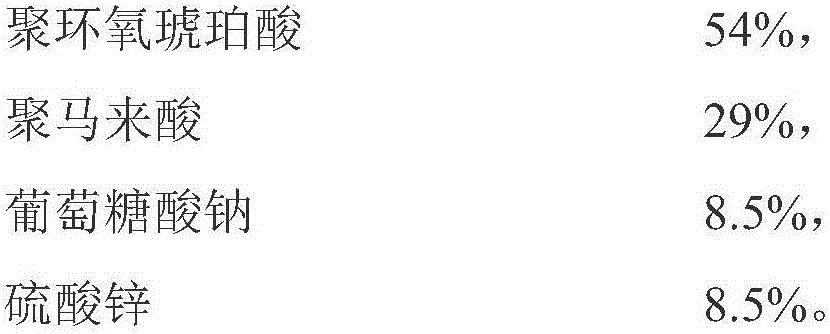

[0043] (1) Polyepoxysuccinic acid, polymaleic acid, sodium gluconate and zinc sulfate are weighed in proportion, and the mass percent is:

[0044] Polyepoxysuccinic acid (PESA) 54%,

[0045] Polymaleic acid (HPMA) 29%,

[0046] Sodium Gluconate 8.5%,

[0047] Zinc sulfate 8.5%.

[0048] (2) Mix polyepoxysuccinic acid, polymaleic acid and sodium gluconate weighed according to the above ratio, heat to 90°C, and keep for 2.0 hours to obtain the first solution;

[0049](3) the zinc sulfate weighing by the above-mentioned ratio is mixed with the zinc sulfate aqueous solution that mass concentration is 10%, in the first solution of above-mentioned step (2), this zinc sulfate aqueous solution is added dropwise, carries out ultrasonic treatment 20 minutes, obtains the second Two solutions;

[0050] (4) Filtrate the above-mentioned second solution, cool the filtrate to normal temperature, and obtain regenerated water to be reused as a phosphorus-free corrosion and scale inhibitor f...

Embodiment 2

[0052] (1) Polyepoxysuccinic acid, polymaleic acid, sodium gluconate and zinc sulfate are weighed in proportion, and the mass percent is:

[0053] Polyepoxysuccinic acid (PESA) 55%,

[0054] Polymaleic acid (HPMA) 30%,

[0055] Sodium Gluconate 10%,

[0056] Zinc sulfate 5%.

[0057] (2) Mix polyepoxysuccinic acid, polymaleic acid and sodium gluconate weighed according to the above ratio, heat to 80°C, and keep for 1.5 hours to obtain the first solution;

[0058] (3) the zinc sulfate weighing by the above-mentioned ratio is mixed with the zinc sulfate aqueous solution that mass concentration is 15%, in the first solution of above-mentioned step (2), this zinc sulfate aqueous solution is added dropwise, carries out ultrasonic treatment 15 minutes, obtains the second Two solutions;

[0059] (4) Filtrate the above-mentioned second solution, cool the filtrate to normal temperature, and obtain regenerated water to be reused as a phosphorus-free corrosion and scale inhibitor for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com