High-temperature-resistant polyester for powder coating and preparation method of high-temperature-resistant polyester

A powder coating, high temperature resistant technology, applied in powder coatings, fire retardant coatings, coatings, etc., can solve problems such as unsatisfactory adhesion and gloss, and achieve equipment cost-free, easy to operate, and simple to prepare. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

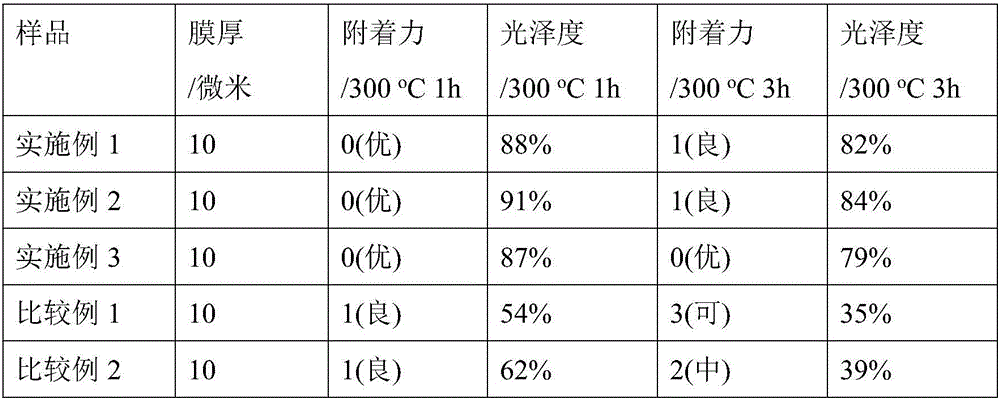

Examples

Embodiment 1

[0032] Prepare the high temperature resistant powder coating polyester of the present invention according to the following method, the method comprises the following steps: 1) add terephthalic acid, isophthalic acid, trimellitic anhydride, neopentyl glycol and tetraisopropyl titanate in a reaction vessel , and its parts by weight are respectively 15 parts, 7 parts, 3 parts, 11 parts and 0.1 part, while adding xylene as a solvent;

[0033] 2) Heat to 170°C to melt all the materials, then add 0.3 parts of triphenyl phosphite, slowly raise the temperature to 220°C, and the heating rate is 10-20°C / h;

[0034] 3) When the temperature is higher than 220°C, control the temperature of the reaction mixture between 220-240°C, and the reaction time is 3-12h;

[0035] 4) Cool down to 180°C, add 1 part of trimethylolpropane, slowly heat up to 220°C to continue the reaction, so that the acid value is less than 10mgKOH / g; then add xylene to form a polyester intermediate solution with a solid...

Embodiment 2

[0041] Prepare the high temperature resistant powder coating polyester of the present invention according to the following method, the method comprises the following steps: 1) add terephthalic acid, isophthalic acid, trimellitic anhydride, neopentyl glycol and tetraisopropyl titanate in a reaction vessel , and its parts by weight are respectively 16 parts, 7.5 parts, 3.5 parts, 12 parts and 0.1 parts, while adding xylene as a solvent;

[0042] 2) Heat to 170°C to melt all the materials, then add 0.3 parts of triphenyl phosphite, slowly raise the temperature to 220°C, and the heating rate is 10-20°C / h;

[0043] 3) When the temperature is higher than 220°C, control the temperature of the reaction mixture between 220-240°C, and the reaction time is 3-12h;

[0044] 4) Cool down to 180°C, add 1.5 parts of trimethylolpropane, slowly raise the temperature to 220°C to continue the reaction, so that the acid value is less than 10mgKOH / g; then add xylene to form a polyester intermediate s...

Embodiment 3

[0050] Prepare the high temperature resistant powder coating polyester of the present invention according to the following method, the method comprises the following steps: 1) add terephthalic acid, isophthalic acid, trimellitic anhydride, neopentyl glycol and tetraisopropyl titanate in a reaction vessel , its parts by weight are respectively 17 parts, 8 parts, 4 parts, 14 parts and 0.1 part, adding xylene simultaneously as solvent;

[0051] 2) Heat to 170°C to melt all the materials, then add 0.3 parts of triphenyl phosphite, slowly raise the temperature to 220°C, and the heating rate is 10-20°C / h;

[0052] 3) When the temperature is higher than 220°C, control the temperature of the reaction mixture between 220-240°C, and the reaction time is 3-12h;

[0053] 4) Cool down to 180°C, add 2 parts of trimethylolpropane, slowly raise the temperature to 220°C to continue the reaction, so that the acid value is less than 10mgKOH / g; then add xylene to form a polyester intermediate sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com