A kind of quick-bonding self-drying emulsion type adhesive and its preparation method and application

An emulsion type and adhesive technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of unclear preparation process conditions, poor stability of water-based adhesives, and reduced adhesive performance, etc., to achieve reduction Effects of oxidation aging rate, improvement of practical performance, and improvement of adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

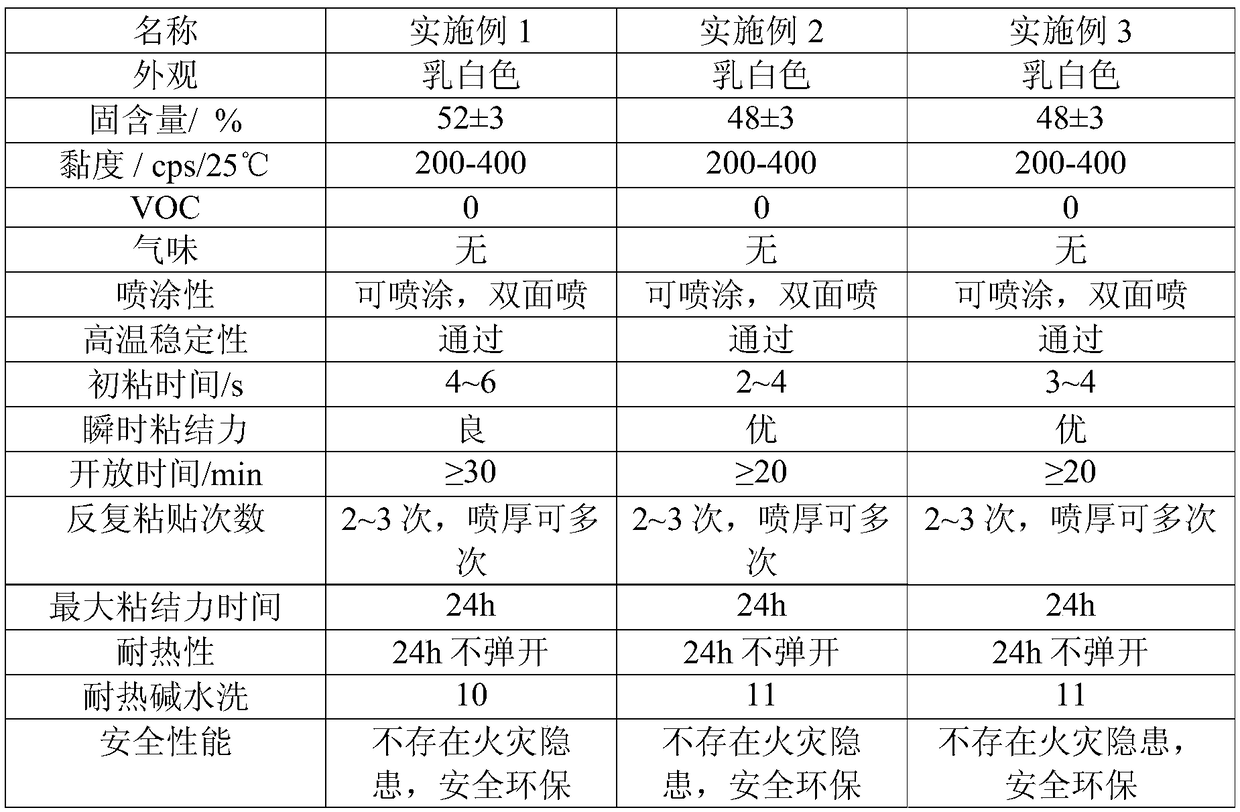

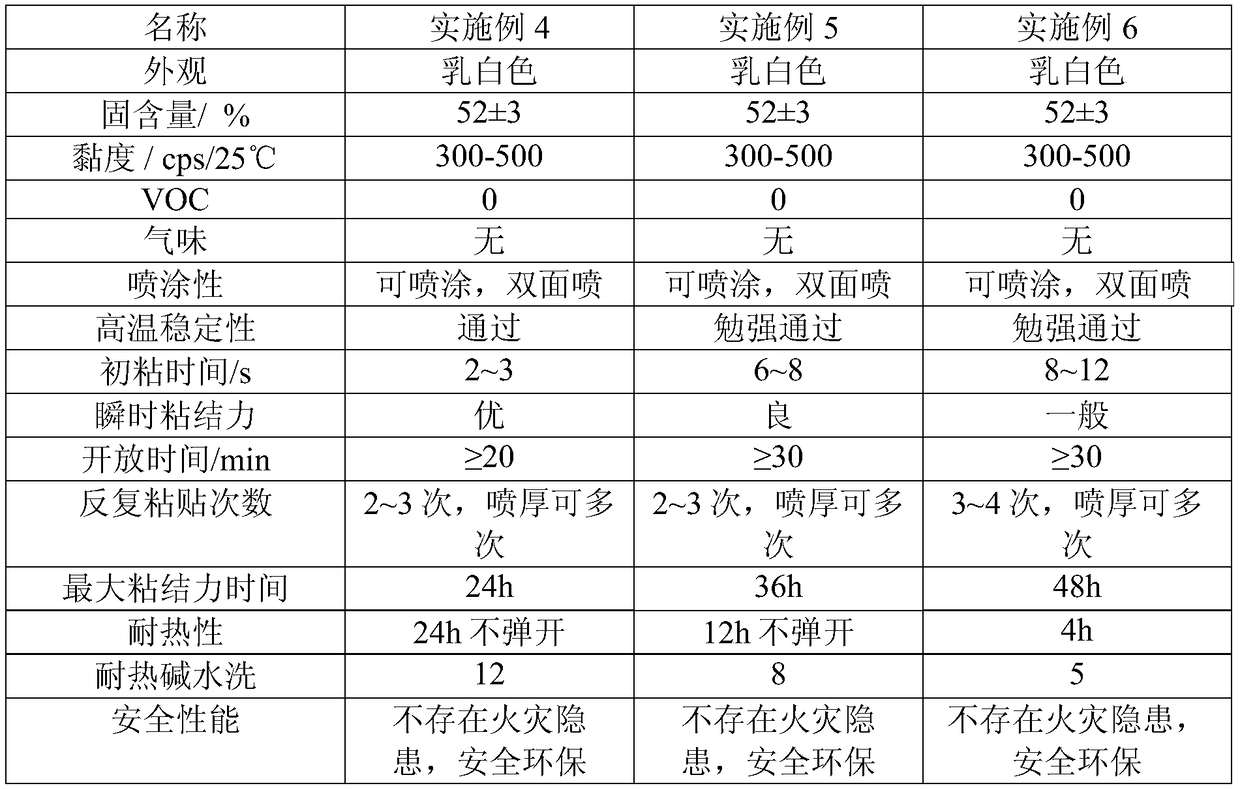

Embodiment 1

[0054] A kind of preparation method of quick-bonding self-drying emulsion type adhesive, comprises the steps:

[0055] (1) Take 50g of acrylate emulsion (particle size is 250~200nm, glass transition temperature is -65°C), and adjust the pH value of the emulsion with Deqian MA-95 amine neutralizer under the stirring condition of 300 rpm Be 9, obtain alkaline acrylate emulsion;

[0056] (2) Take 0.75g of hydrophilic fumed nano-silica (with a particle size below 100nm) and dissolve it in 7.5g of deionized water; add 0.15g of Deqian Disponer W-519 anionic wetting and dispersing agent to disperse evenly, Then add 0.75g nanometer zinc oxide dispersion liquid to disperse evenly, obtain mixed solution;

[0057] (3) Add the mixed solution prepared in step (2) into the alkaline acrylate emulsion in step (1), and disperse for 10 minutes under stirring conditions at 500 rpm to obtain a mixed solution containing acrylate;

[0058] (4) Take by weighing 80g high crystallization rate water-...

Embodiment 2

[0062] A kind of preparation method of quick-bonding self-drying emulsion type adhesive comprises the steps:

[0063] (1) Take 60g of acrylate emulsion (with a particle size of 150-200nm and a glass transition temperature of -60°C), and adjust the pH value of the emulsion to 10 with ethylenediamine under the stirring condition of 400 rpm to obtain an alkaline Acrylic emulsion;

[0064] (2) Weigh 1.2g of hydrophilic fumed nano-silica with a particle size of 70 nm or less, dissolve it with 9.6g of deionized water; add 0.24g of Deqian Disponer W-519 anionic wetting and dispersing agent to disperse evenly, Add 1.2g of nano-zinc oxide dispersion liquid to disperse evenly to obtain a mixed solution;

[0065] (3) Add the mixed solution prepared in step (2) into the alkaline acrylate emulsion in step (1), and disperse for 15 minutes under stirring conditions at 400 rpm to obtain a mixed solution containing acrylate;

[0066] (4) Take by weighing 60g high crystallization rate water-b...

Embodiment 3

[0070] A kind of preparation method of quick-bonding self-drying emulsion type adhesive comprises the steps:

[0071] (1) Take 80g of acrylate emulsion (with a particle size below 150nm and a glass transition temperature of -65°C), and adjust the pH value of the emulsion to 10 with ethylenediamine under the stirring condition of 400 rpm to obtain basic acrylic acid Ester emulsion;

[0072] (2) Weigh 2.16g of hydrophilic fumed nano-silica (particle size is less than 70 nanometers), dissolve it with 12.6g of deionized water; add 0.45g of BYK-152 water-based polyacrylate ammonium salt wetting and dispersing agent to disperse evenly , adding 2.25g of nano-zinc oxide dispersion liquid to disperse evenly to obtain a mixed solution;

[0073] (3) Add the mixed solution prepared in step (2) into the alkaline acrylate emulsion in step (1), and disperse for 15 minutes under stirring conditions at 400 rpm to obtain a mixed solution containing acrylate;

[0074] (4) Take by weighing 40g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com