CMOS process integrated temperature sensor used for TEC-free infrared imaging system

An infrared imaging system and temperature sensor technology, which is used in thermometers, thermometers, instruments and other directions that use electrical/magnetic components that are directly sensitive to heat, can solve the problem that the temperature sensor cannot accurately detect the temperature of the detector chip substrate, and achieve accurate detection. The effect of reflecting the temperature change of the chip substrate, reducing the number of MOS, and simplifying the circuit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in combination with specific embodiments.

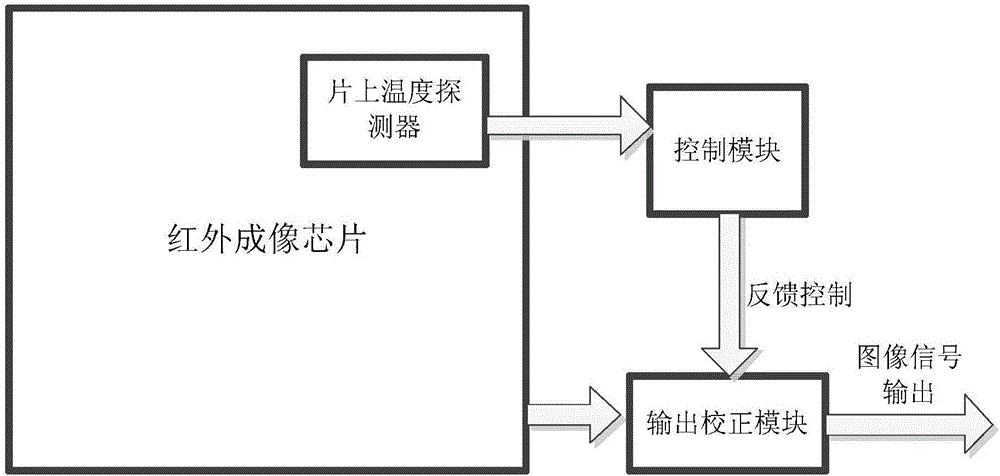

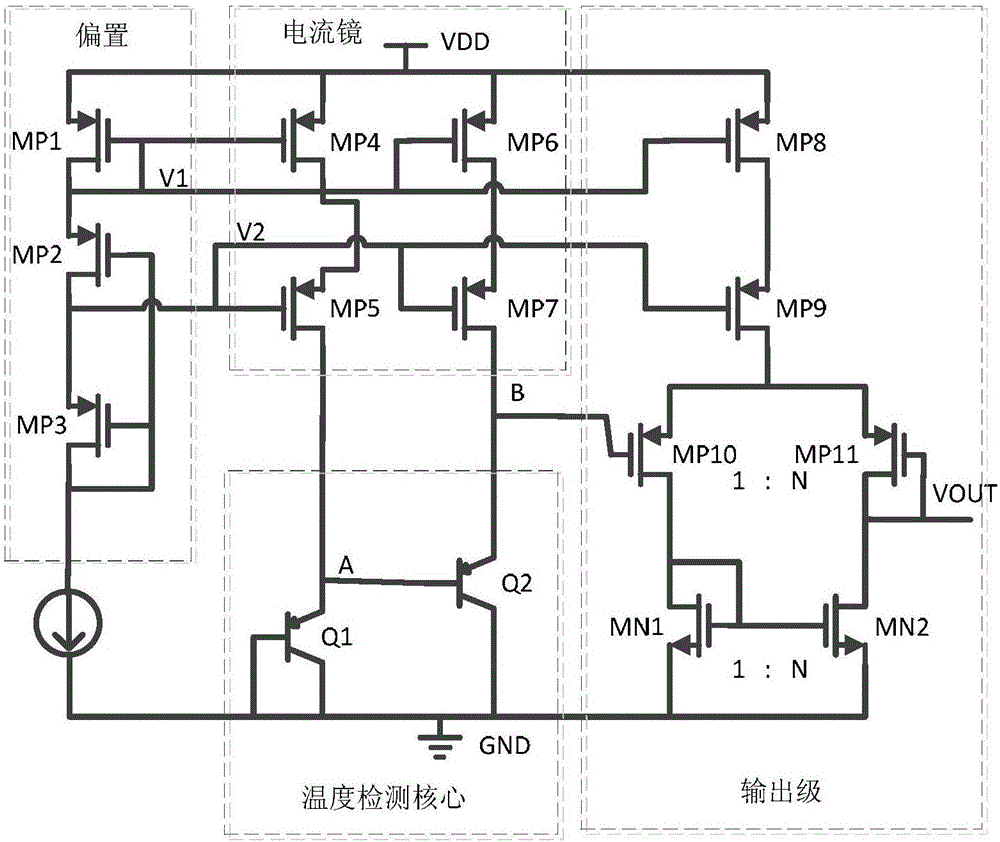

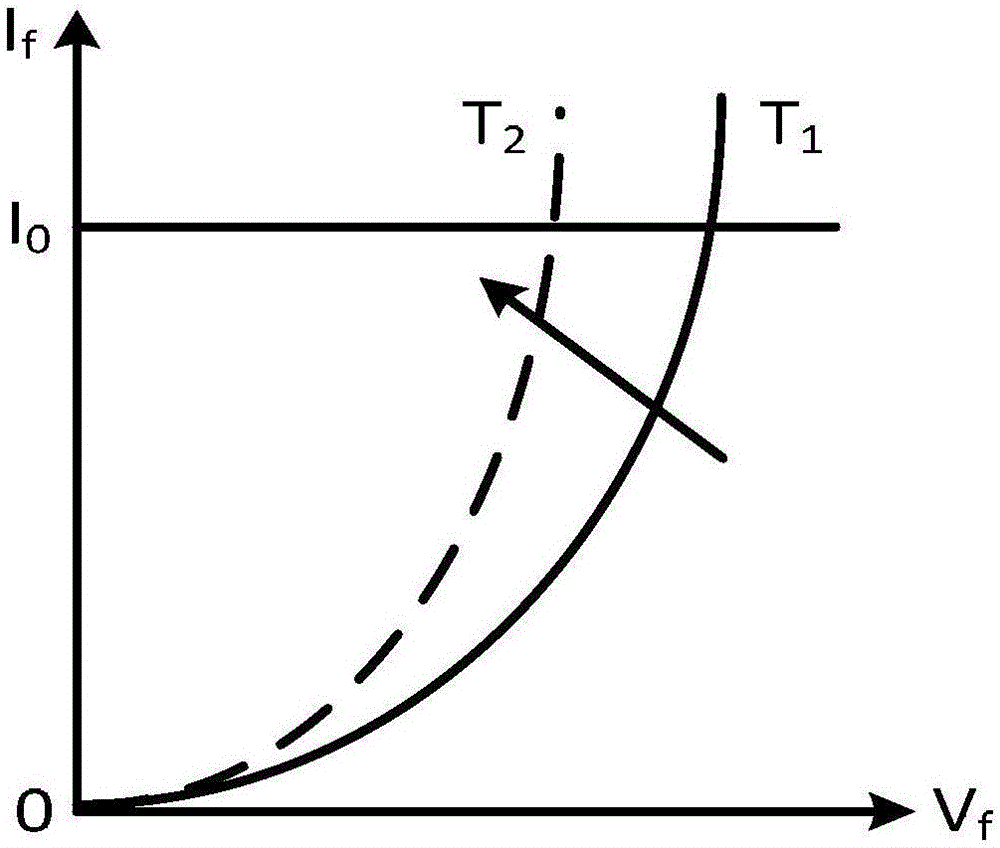

[0018] In order to solve the problem that the traditional discrete component temperature sensor cannot meet the requirements of the non-TEC infrared imaging system to accurately detect the substrate temperature of the detector chip, the present invention proposes a CMOS process integrated temperature sensor for the non-TEC infrared imaging system, which can save area and reduce power consumption, see attached figure 1 . Since the diodes in the standard CMOS process usually work under the condition of reverse bias, it is difficult to meet the requirements for using the diodes in the forward bias. The present invention equivalently realizes the effect of the diodes in forward bias series by using the form of series connection of triodes. The temperature is detected by using the temperature characteristics of the forward-biased diode, and the detection result is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com