Pretreatment device and pretreatment method for electrode active material for supercapacitor

A technology of electrode active materials and supercapacitors, applied in the manufacture of hybrid/electric double layer capacitors, etc., can solve the problem of insufficient cycle life of monomers, and achieve the effect of high capacity and low surface functional group content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

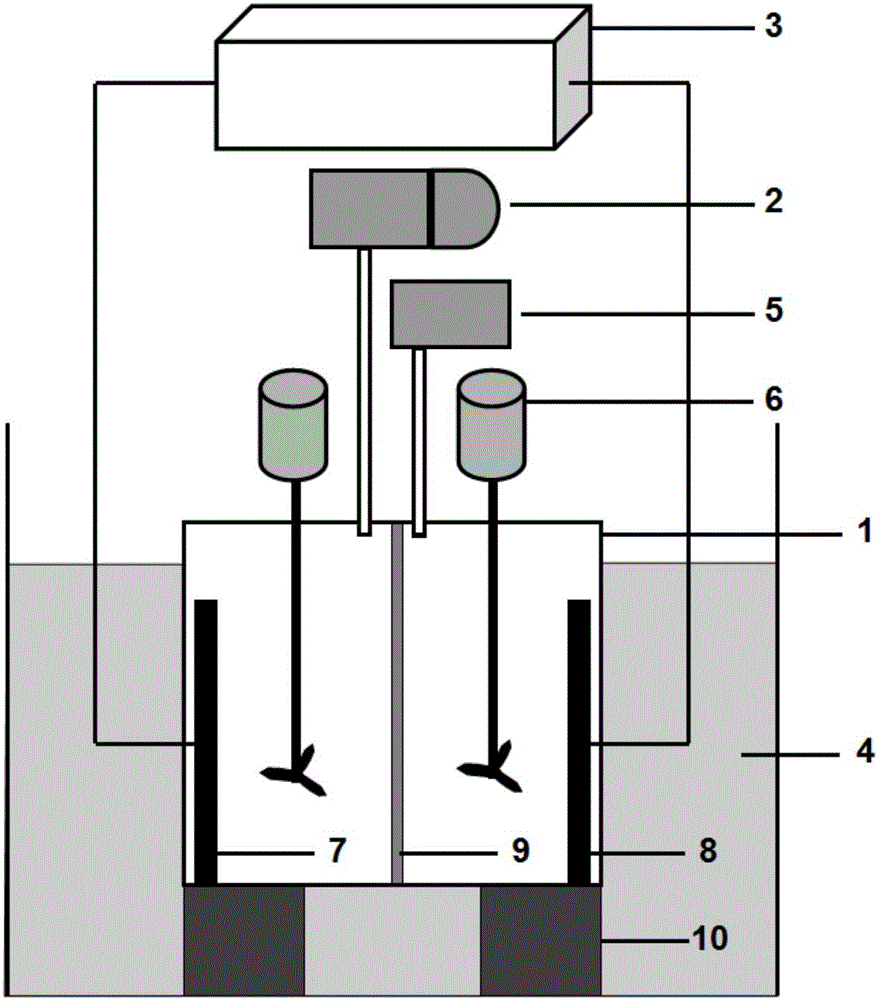

Image

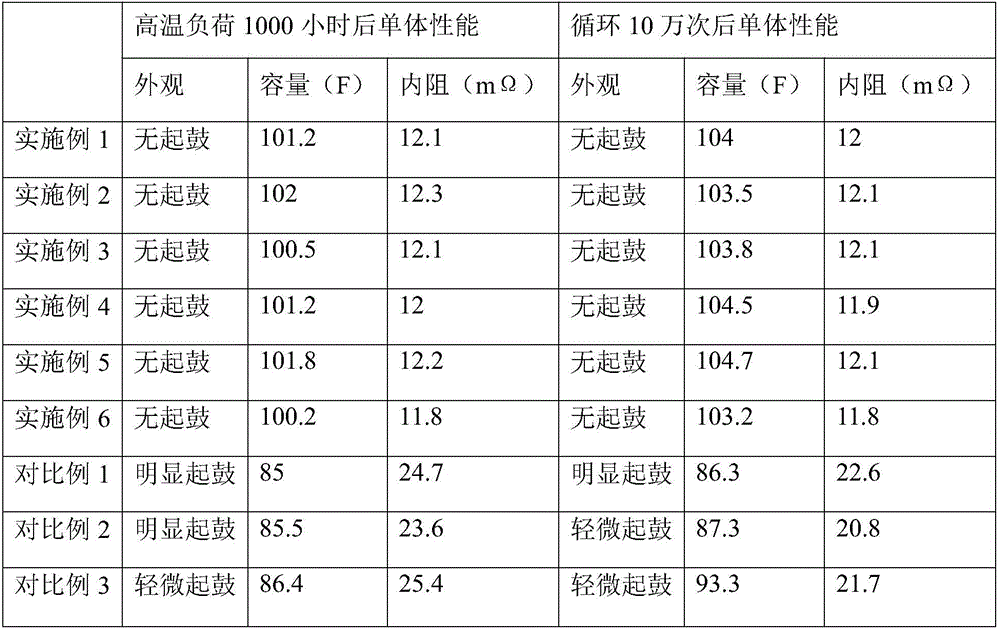

Examples

Embodiment 1

[0025] Take by weighing 1000 grams of activated carbon for supercapacitors and add them to the positive electrode area and the negative electrode area of the reactor stack respectively, seal the reactor stack, and vacuumize the reactor stack to -0.098MPa with a vacuum pump; inject 2000 MPa into the reactor stack with a liquid injection pump The solution of gram 1M tetraethylammonium tetrafluoroboric acid in acetonitrile, stir the positive electrode region and the negative electrode region of the reactor pile with a stirrer respectively, make the supercapacitor use activated carbon and the solution of 1M tetraethylammonium tetrafluoroboric acid in acetonitrile to form a solid A slurry with a content of 33.3wt%; adjust the temperature of the constant temperature water bath to 60°C, and after the temperature of the reactor pile is stable, connect the positive electrode current collector and the negative electrode collector of the reactor pile with a charge and discharge tester, a...

Embodiment 2

[0028]Weigh 1,000 grams of graphene and add them to the positive and negative regions of the reactor stack, seal the reactor stack, and use a vacuum pump to evacuate the reactor stack to -0.098MPa; inject 1,500 grams of 1M into the reactor stack with a liquid injection pump. For the solution of tetraethylammonium tetrafluoroboric acid in propylene carbonate, stir the positive electrode area and the negative electrode area of the reactor pile with a stirrer respectively, so that the solution of graphene and 1M tetraethylammonium tetrafluoroboric acid in propylene carbonate forms a solid Content is the slurry of 40wt%; Regulate the temperature of constant temperature water bath to 70 ℃, after the reactor stack temperature reaches stable, connect the positive electrode collector and the negative electrode collector of the reactor stack with the charge and discharge tester, the reactor stack is constant Flow charge to 2.5V, then charge the reactor pile at a constant voltage of 2....

Embodiment 3

[0031] Weigh 1,000 grams of activated carbon fibers and add them to the positive and negative regions of the reactor stack, seal the reactor stack, and vacuum the reactor stack to -0.098MPa with a vacuum pump; inject 3,000 grams of 1M into the reactor stack with a liquid injection pump. The solution of triethylmethylammonium tetrafluoroboric acid in propylene carbonate, stir the positive electrode area and the negative electrode area of the reactor stack with a stirrer respectively, so that activated carbon fiber and 1M triethylmethylammonium tetrafluoroboric acid are mixed in propylene carbonate The solution in the solution forms a slurry with a solid content of 25wt%; adjust the temperature of the constant temperature water bath to 70 ° C, and after the temperature of the reactor stack is stable, connect the positive electrode current collector and the negative electrode current collector of the reactor stack with a charge and discharge tester. Charge the reactor pile with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com